One-time molding device for cord gluing and conveyor belt cord layer

A molding device and conveyor belt technology, which is applied to the surface coating liquid device, coating, etc., can solve the problems of long time consumption, low efficiency, complicated process, etc., and achieve high efficiency, simple molding process and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

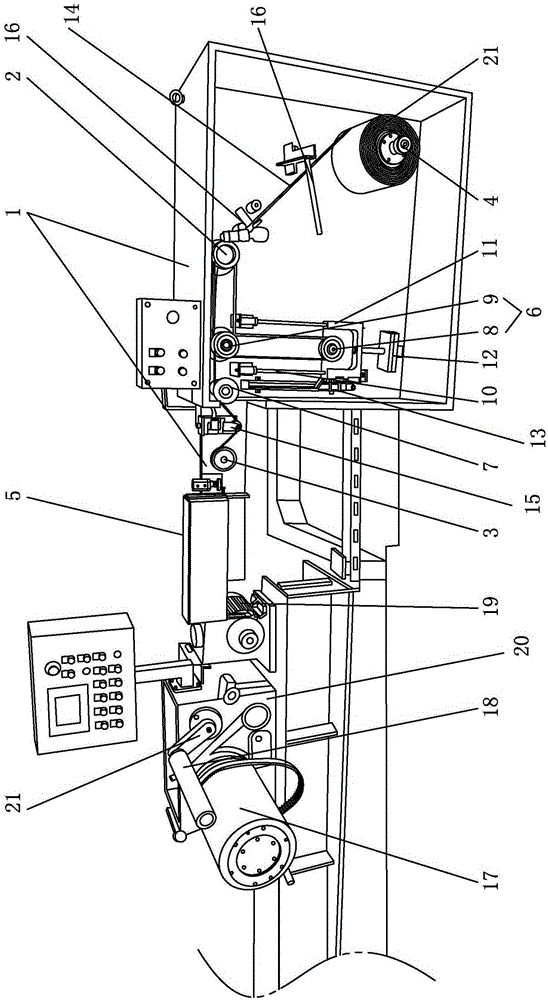

[0018] The present invention will be further described below with specific embodiment, see figure 1 :

[0019] A one-time molding device for cord gluing and conveyor belt cord layer. An input roller 2 and an output roller 3 are arranged on a frame 1, and several rollers are arranged between the input roller 2 and the output roller 3. One side of the roller 2 is provided with a rope roller 4, one side of the output roller 3 is provided with a molten rubber container 5, and one side of the molten rubber container 5 is provided with a winding drum, and the winding drum is driven by power to rotate.

[0020] A first roller 6 and a second roller 7 are arranged between the above-mentioned input roller 2 and the output roller 3, and the first roller 6 includes an upper roller 9 and a lower roller 8 arranged at intervals up and down, upper and lower rollers 9, The center distance between 8 is adjustable.

[0021] The adjustable center distance between the above-mentioned upper and l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com