Color ring printing and coloring one-step forming technology and device for optical fibers

A molding process and optical fiber technology, applied in cladding optical fiber, optical waveguide and light guide, etc., can solve problems such as waste of production efficiency, equipment redundancy, and increased risk of fiber breakage, so as to simplify equipment, improve production efficiency, and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

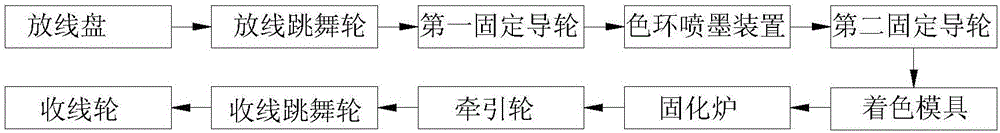

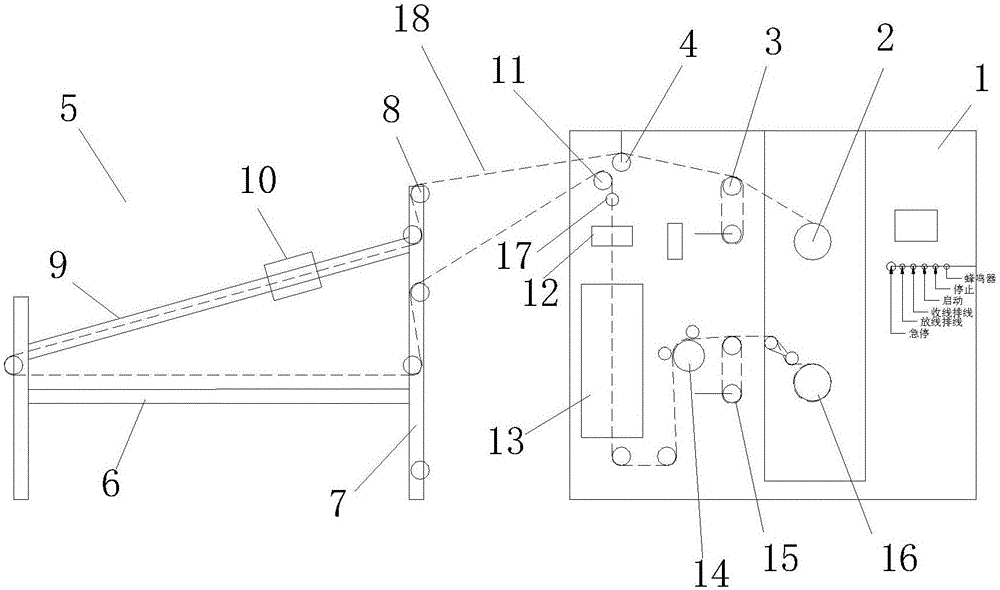

[0012] Embodiment: the color ring of the optical fiber and the coloring one-time molding process, as attached figure 1 and figure 2 As shown, the color ring inkjet device and the coloring mold are installed on the machine base at the same time, so that the optical fiber can perform color ring inkjet and fiber coloring at the same time, and improve the production efficiency of the optical fiber. Specifically, the process first uses the optical fiber pay-off reel to pay off, and then enters the inkjet ring machine through the pay-off dancing wheel and the first fixed guide wheel to perform color ring inkjet, then solidifies and dries, and then passes through the transition guide wheel and the first fixed guide wheel. The second fixed guide wheel enters the coloring mold for optical fiber coloring, then is cured in a curing oven, and finally enters the optical fiber take-up reel through the traction wheel and the take-up dancing wheel to take up the line. Still further, a singl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com