End part metal piece structure for transmission insulating rod of gas insulated switchgear and manufacturing method of end part metal piece structure

A technology of gas insulated switches and insulating rods, which is applied to the setting of switchgear, electric switches, switchgear, etc., can solve problems such as poor interface bonding performance, and achieve the goal of improving strength, enhancing bonding strength, and ensuring reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

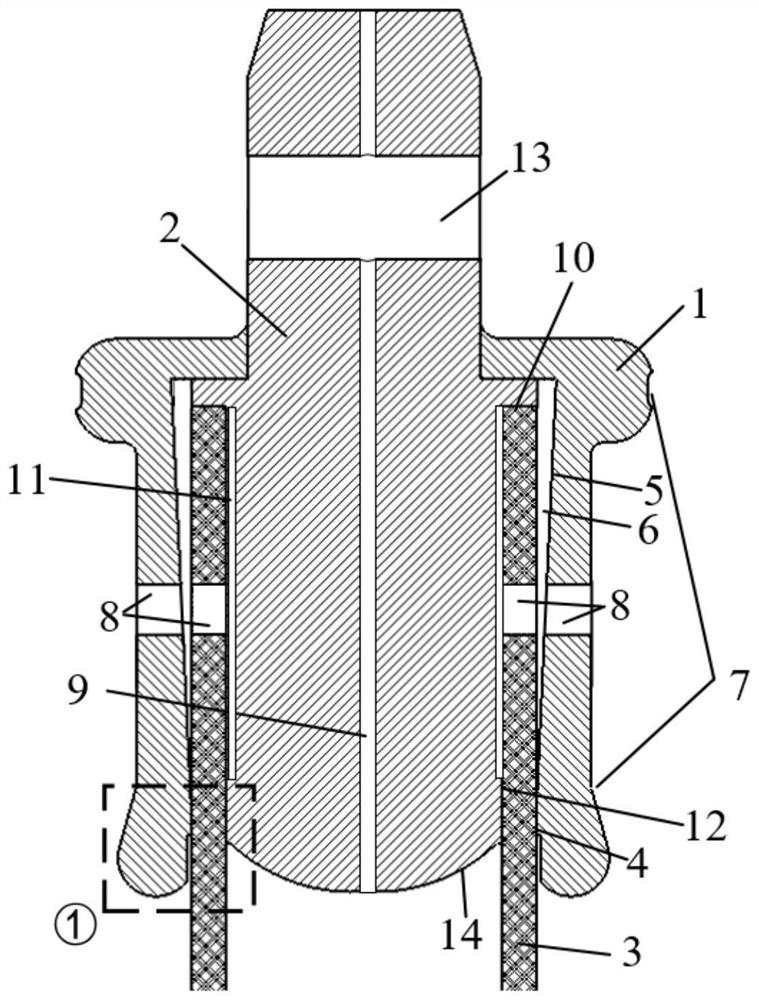

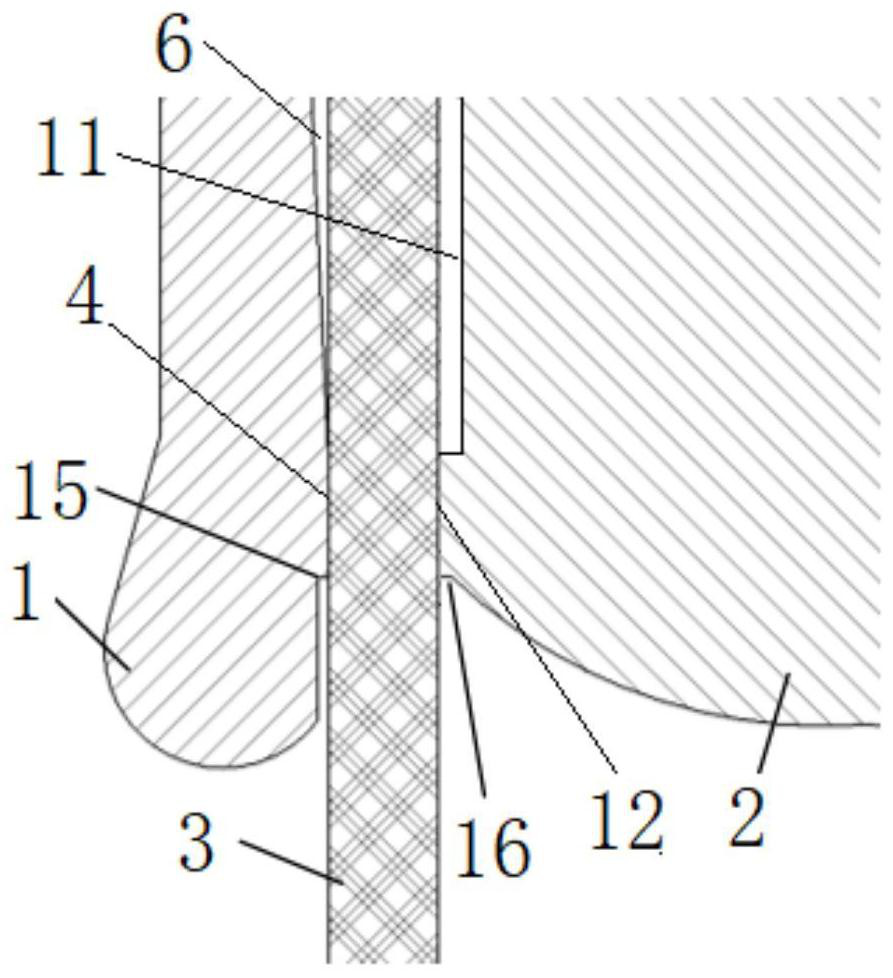

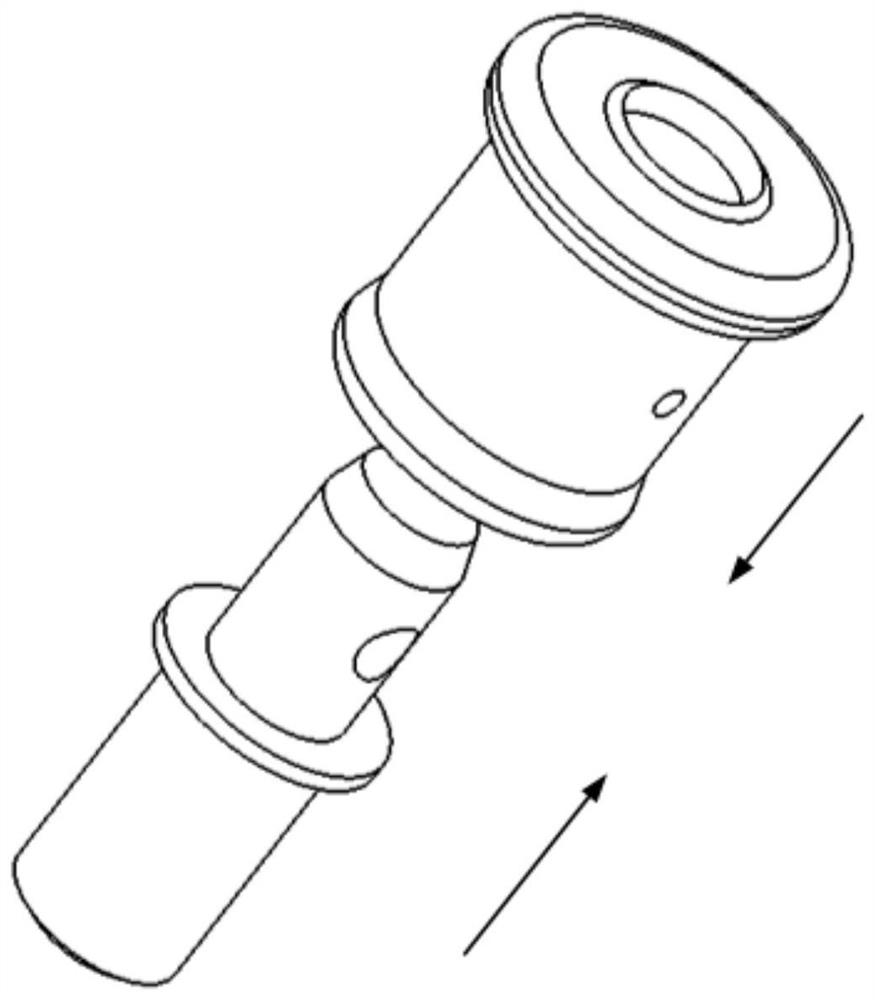

[0043] Such as Figure 1-Figure 3 As shown, in the following description of this embodiment, all use figure 1 and figure 2 The orientation shown is taken as an example for illustration. This embodiment is used for the end metal part structure of the transmission insulating rod of the gas insulated switchgear, including the outer sleeve 1, the metal insert 2, and the fiber-reinforced epoxy as the main insulating body of the pull rod. Composite pipe 3, the inner profile of the outer sleeve 1 includes a second parallel section 4 forming an interference fit with the fiber reinforced epoxy composite pipe 3, an inclined section 5 forming a certain angle with the fiber reinforced epoxy composite pipe 3, and a second Two chamfers 15, a wedge-shaped bonding section 6 (that is, the glue injection cavity) is formed between the inclined section 5 and the fiber-reinforced epoxy composite pipe 3 . The outer contour of the outer sleeve 1 includes an annular groove 7, and the annular groov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com