Sheet glue and gluing method thereof

A sheet and colloid technology, applied in the direction of bonding methods, film/sheet adhesives, adhesives, etc., can solve the problems of waste of adhesive, poor bonding, easy formation of air bubbles, etc., to achieve easy sizing, Reduce waste and ensure the effect of adhesive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

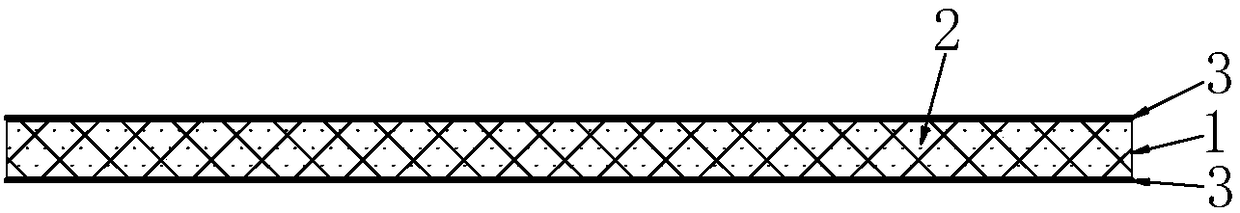

[0029] Such as figure 1 As shown, the present invention provides a single-component sheet glue, including a sheet carrier 1, a colloid 2 and an isolation film 3, the sheet carrier 1 has a plurality of non-closed accommodation spaces densely distributed, wherein, The non-enclosed accommodation space can be a hole or a similar cavity formed in a single-layer grid cloth, or a regular or irregular-shaped grid or a similar cavity in a three-dimensional grid cloth, or a multi-layer grid cloth The pores or similar cavities in the interior, or the micropores or similar cavities in the polymer sheet skeleton with micropores, or the pores or similar cavities in the fiber cloth interwoven with natural fibers, synthetic fibers or mixed fibers cavity, and the material of the sheet carrier is a material that does not react with the colloid and has good stability, such as non-woven fabrics, woven fabrics, fiber fabrics, polymer sheet skeletons with micropores, or sheet-like mesh adhesive fil...

Embodiment 2

[0034] For this embodiment 1, embodiment 2 of the present invention also provides the gluing method of this one-component sheet glue, comprises the following steps:

[0035] S1, providing the sheet glue as described in the above-mentioned embodiment 1;

[0036] S2. Remove the isolation film of the sheet glue and place it on the surface to be glued;

[0037] S3, providing curing conditions, so that the sheet glue is cured.

[0038] The above-mentioned one-component adhesive sheet material can be taken according to the size of the pasting interface, reducing the waste of adhesive materials. Moreover, the unused part is placed in a sealed package state and will not cure, which is convenient for long-term adhesive operations. There is no need for stirring and other actions, and it also avoids the generation of air bubbles, especially in the narrow bonding interface, which can facilitate sizing and effectively avoid the problem of incomplete adhesion.

Embodiment 3

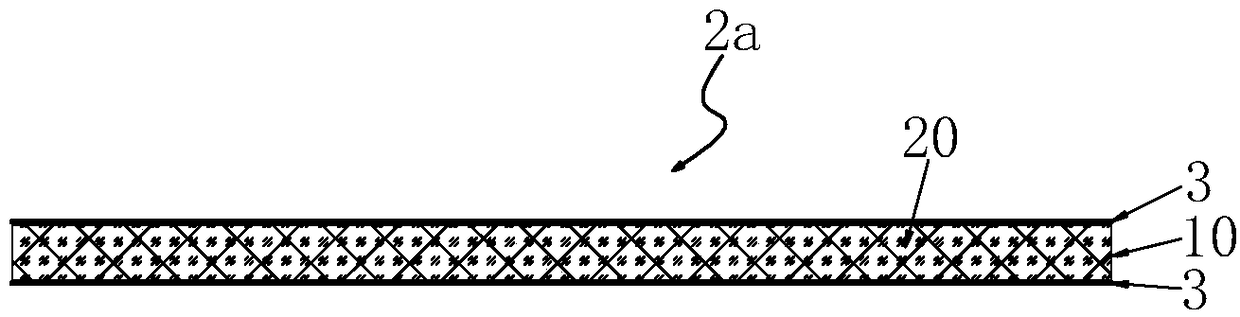

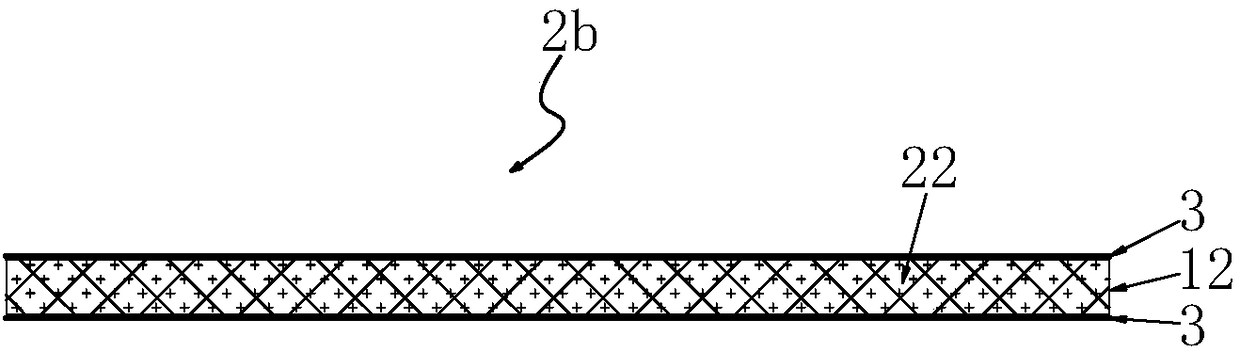

[0040] refer to figure 2 with image 3 , figure 2 with image 3Shown is the schematic diagram of the two-component sheet glue, including the first sheet carrier 10, the second sheet carrier 12, the first glue 20, the second glue 22 and the isolation film 3, wherein the first glue, the second Colloid is respectively one of this glue and curing agent, and described sheet material carrier 1 comprises first sheet material carrier 10 and second sheet material carrier 12, all has densely distributed in described first sheet material carrier and second sheet material carrier A plurality of non-enclosed accommodation spaces, wherein the non-enclosed accommodation spaces can be pores or similar cavities formed in a single-layer mesh cloth, or regular or irregularly shaped grids or grids in a three-dimensional mesh cloth. Similar cavities, or pores or similar cavities in multi-layer grid cloth, or micropores or similar cavities in the polymer sheet skeleton with micropores, or made...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com