Aldehyde-free soybean modified wood bonding agent and method for preparing same

A wood adhesive and modification technology, which is applied in the preparation of adhesive, animal glue or gelatin, adhesive type, etc., can solve the problems of low bonding strength, high viscosity, high production cost, etc., and achieve the effect of saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

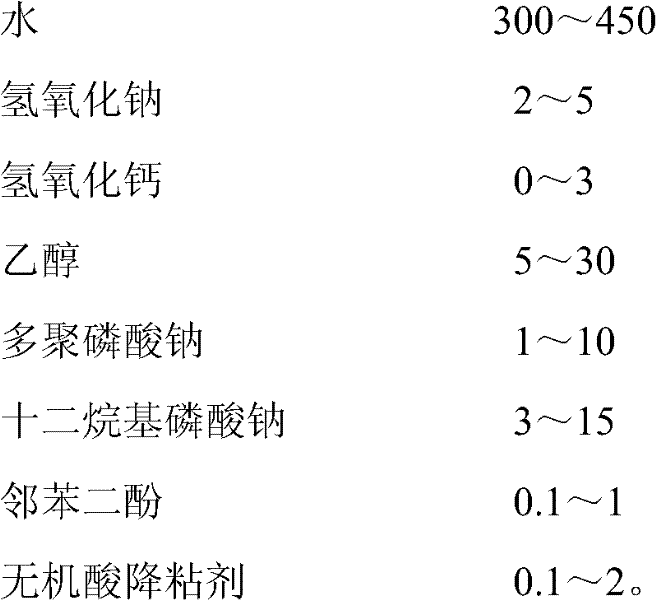

Method used

Image

Examples

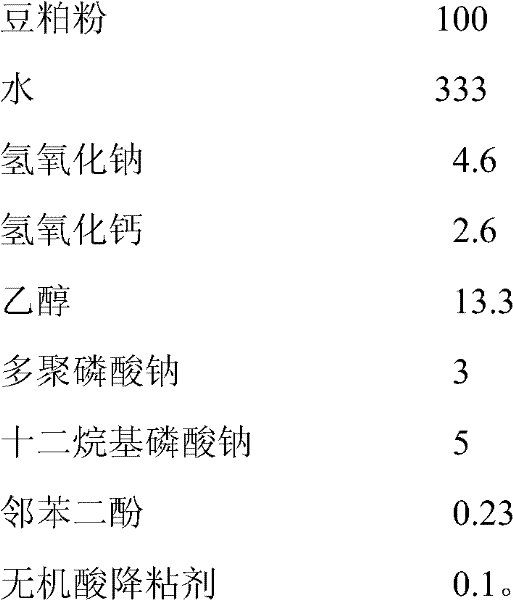

Embodiment 1

[0045] Prepare the formaldehyde-free soybean modified wood adhesive of the present invention according to the following steps

[0046] a material preparation

[0047] ①Soybean meal crushing

[0048] The dried soybean meal is pulverized, passed through a 100-mesh sieve, and set aside;

[0049] ②. Respectively prepare the composite crosslinking agent raw materials into an aqueous solution

[0050] Among them, 3 parts by weight of sodium polyphosphate containing an appropriate amount of antifoaming agent is prepared into a 5-40% aqueous solution; 5 parts by weight of sodium dodecyl phosphate is prepared into a 0.1-30% aqueous solution, and phthalate 0.23 parts by weight of phenol, prepared as a 0.1-5% aqueous solution, for subsequent use;

[0051] ③. 0.1 parts by weight of the inorganic acid viscosity reducer is prepared into a 0.1-5% aqueous solution for subsequent use;

[0052] b. Alkali, ethanol mixed solution denaturation treatment

[0053] According to the proposed form...

Embodiment 2~ Embodiment 6

[0074] According to the method and steps of Example 1, prepare the formaldehyde-free soybean modified wood adhesive of the present invention according to the formula in Table 1

[0075] Table 1

[0076] raw material

[0077] Catechol

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Bonding strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com