Nanometer material surface glue spreading device

A technology of gluing device and nano-materials, which is applied to devices and coatings for coating liquid on the surface, can solve the problems of single function, increase the cost of nano-sheets, and low working efficiency of the device, so as to improve the filling efficiency and enhance the Convenience and functionality, the effect of a convenient gluing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

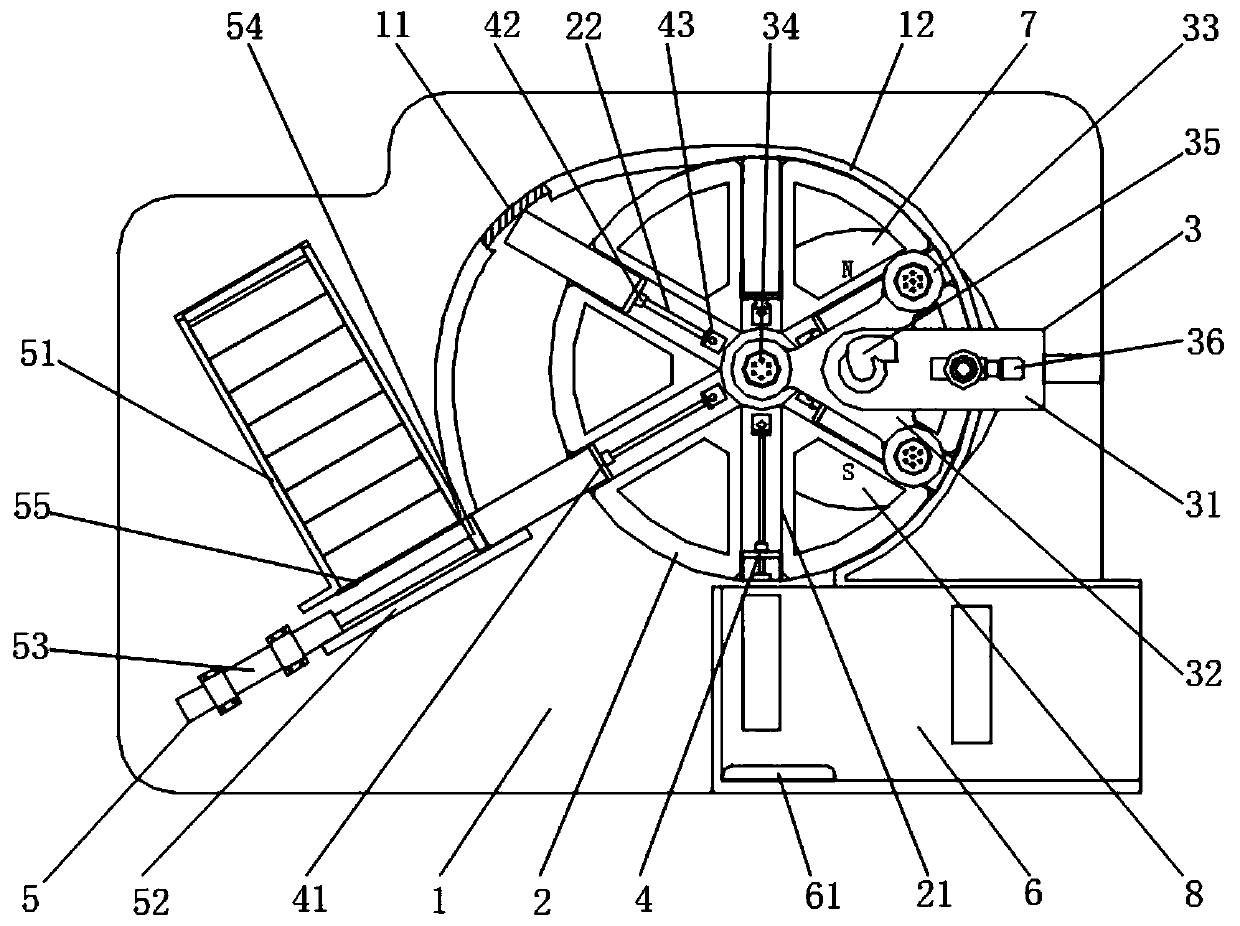

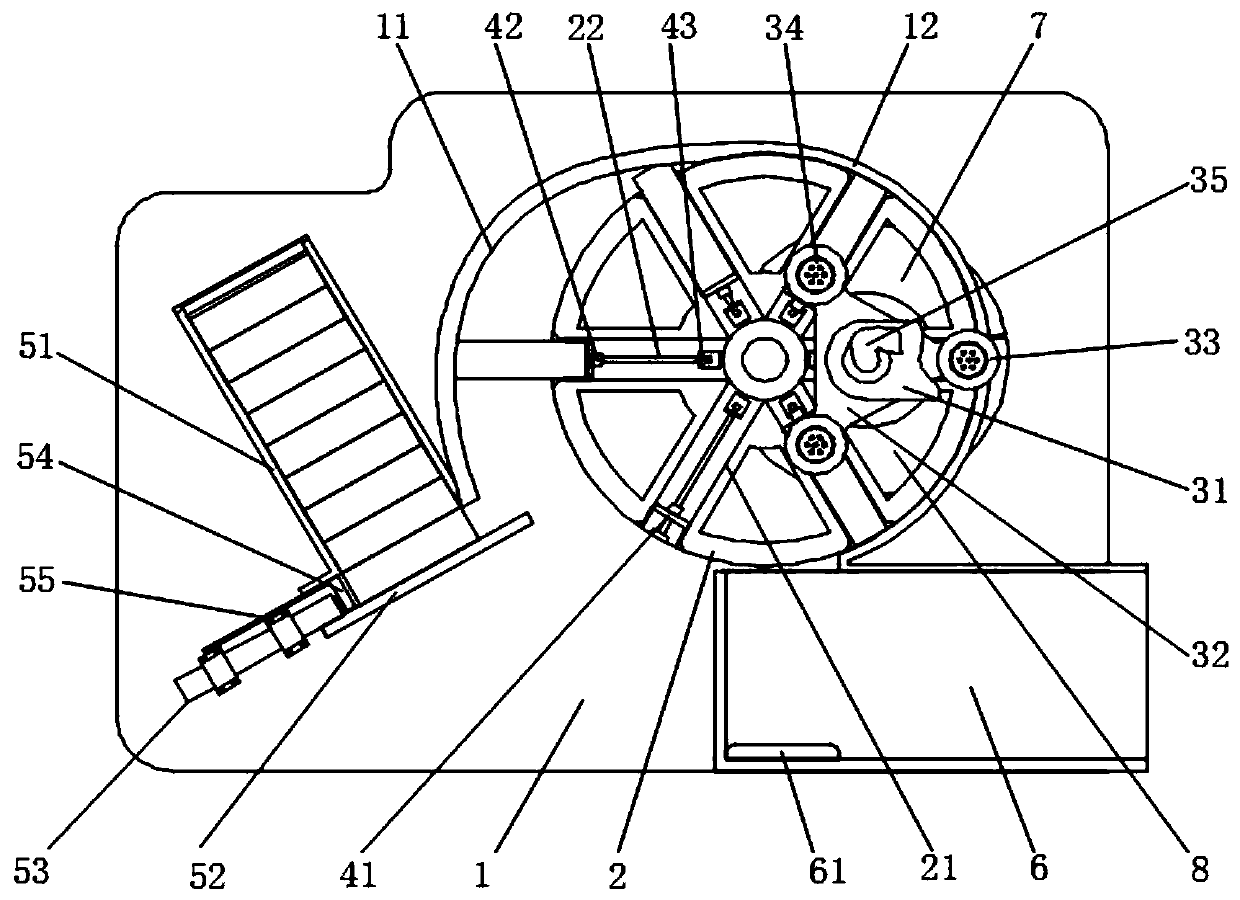

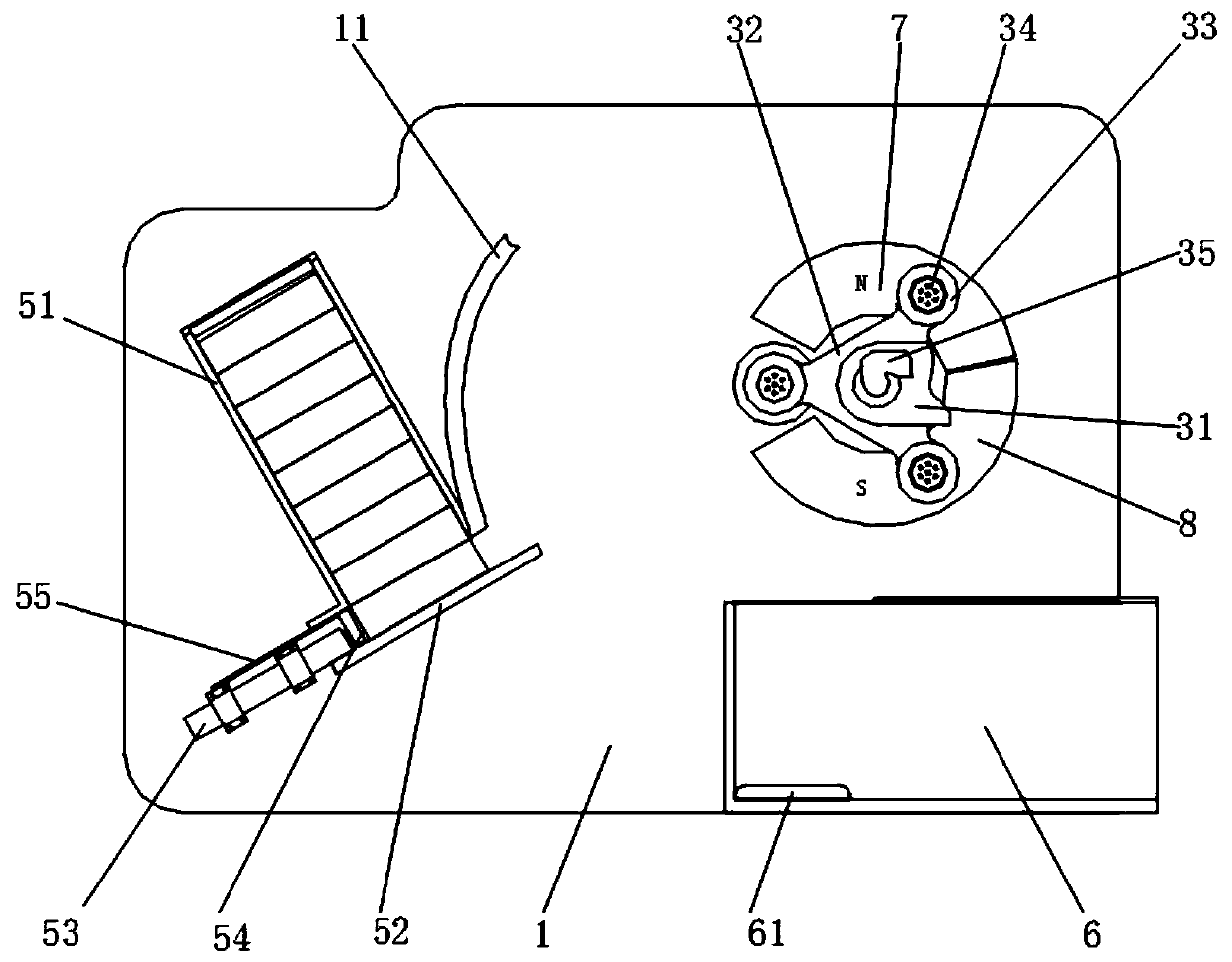

[0031] The present invention provides such Figure 1-8A kind of nano material surface gluing device shown, comprises workbench 1, and the top of described workbench 1 is provided with turntable 2, and the top of described turntable 2 is evenly opened with six T-shaped chute 22, and six The T-shaped chute 22 is radially distributed on the top of the turntable 2, the bottom of the turntable 2 is fixedly connected with a rotating shaft 23, and the bottom end of the rotating shaft 23 runs through the workbench 1 and is rotatably connected with the workbench 1. A gear ring 24 is fixedly installed on the outside of the bottom end of the rotating shaft 23, and a drive motor 25 is fixedly installed on the bottom of the workbench 1. The drive motor 25 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com