Liquid crystal glass waste crushing and recycling equipment

A technology of liquid crystal glass and recycling equipment, applied in the direction of using liquid separation agent, removal of solid waste, fixed filter element, etc. The effect of recycling processing efficiency, improving safety, enhancing functionality and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

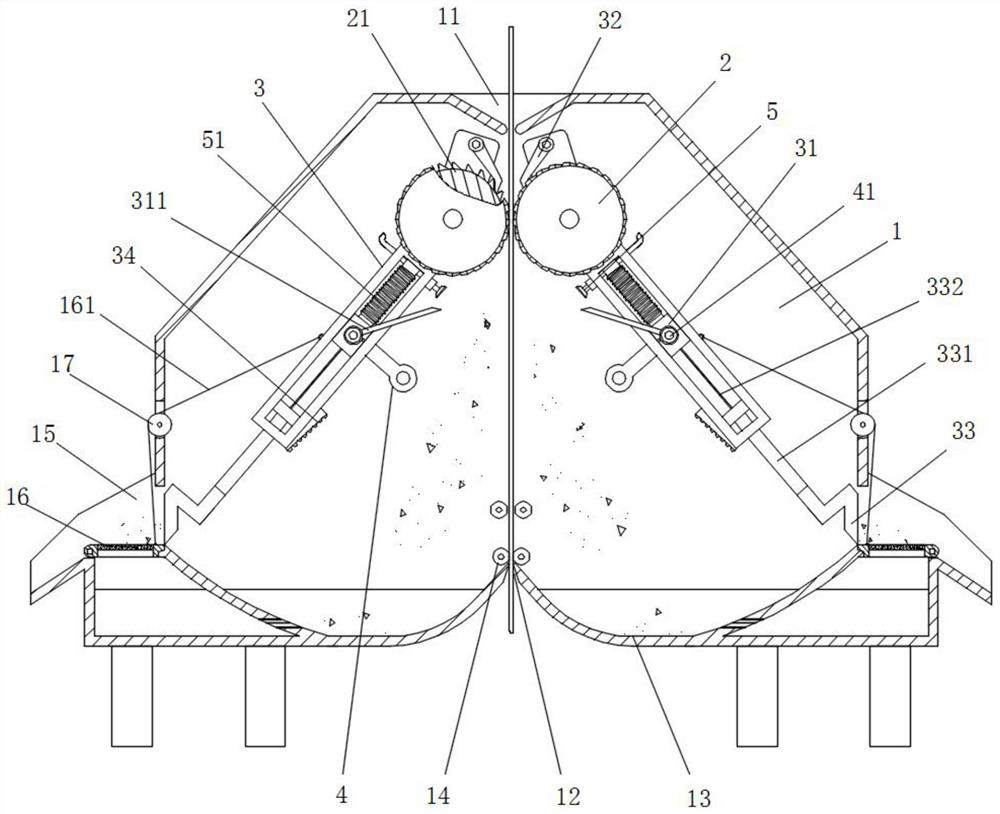

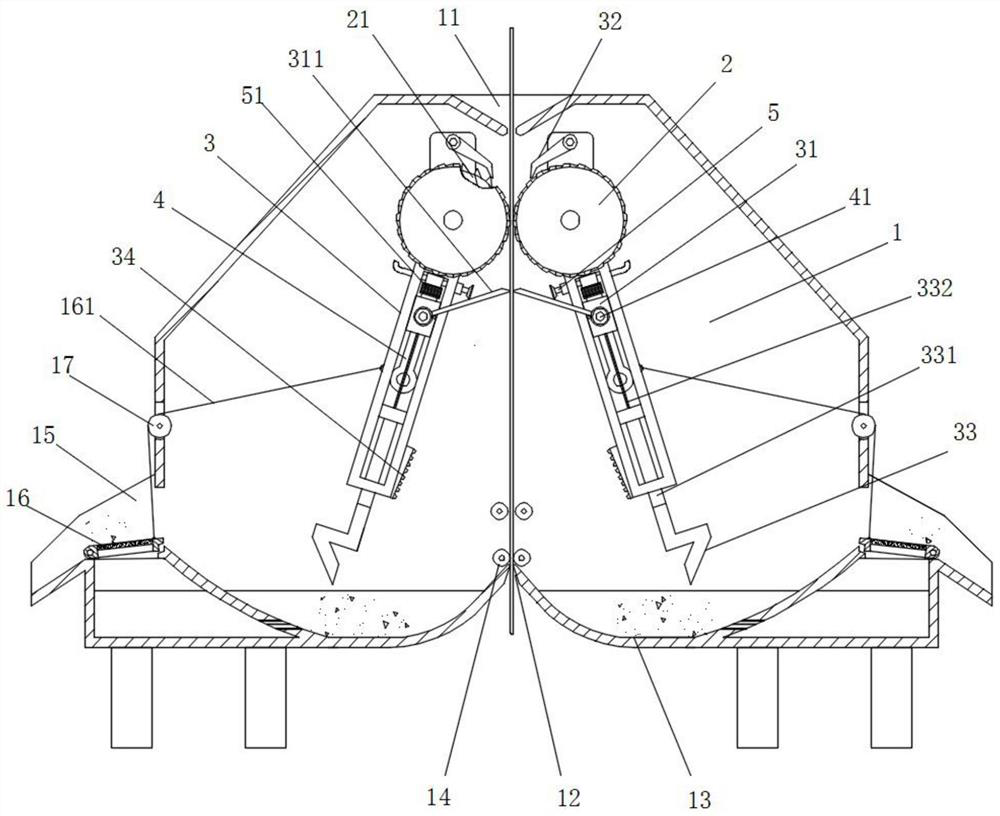

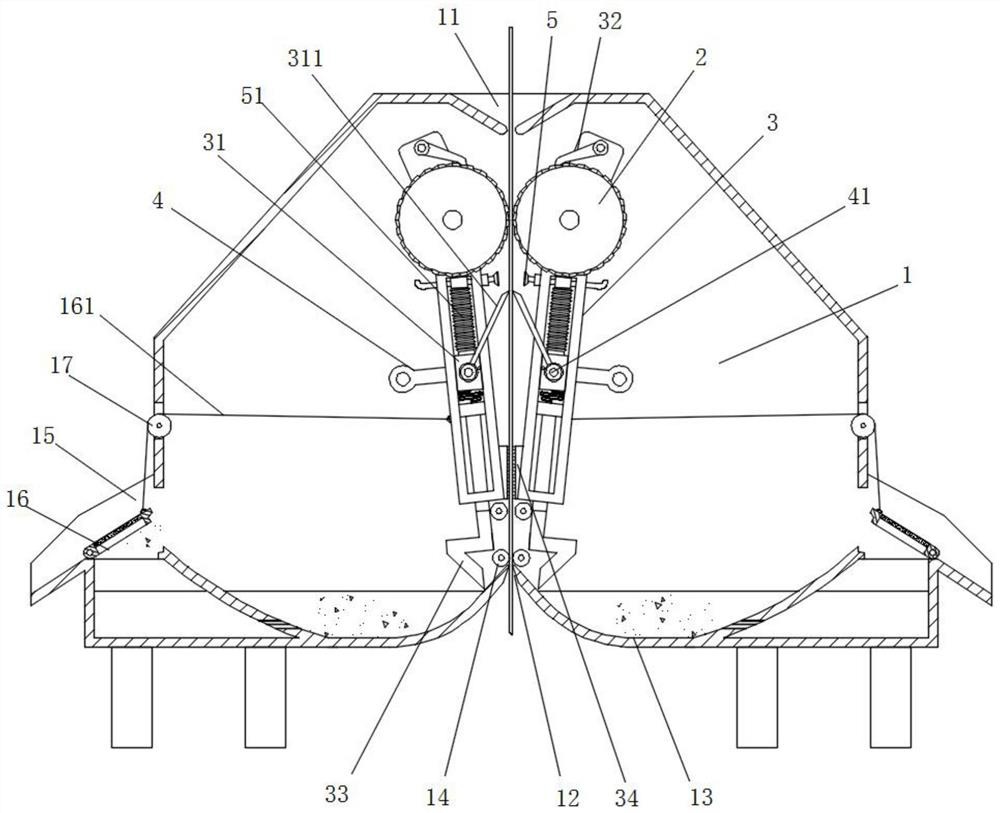

[0028] The present invention provides such Figure 1-5 A liquid crystal glass waste crushing and recycling equipment shown includes a cabinet 1, the top of the cabinet 1 is provided with an input port 11, and the bottom of the cabinet 1 is provided with a film outlet 12, and the film outlet 12 corresponds to the input port 11, the two sides of the film outlet 12 are set as an arc-shaped bottom chamber 13, and the arc-shaped bottom chamber 13 stores the processing liquid. The inside of the cabinet 1 is symmetrically provided with two groups of crushing mechanisms, and the crushing mechanisms include Rotate the crushing roller 2 installed inside the cabinet 1, the two groups of crushing rollers 2 mesh with each other, the end of the crushing roller 2 is rotatably installed with a pendulum 3, and the inner wall of one side of the cabinet 1 is rotatably installed with two sets of drive Fork 4, two groups of said driving fork 4 are rotated and driven by external drive equipment, an...

Embodiment 2

[0036] Based on Example 1, the difference is that, as Figure 1-4 A liquid crystal glass waste crushing and recycling equipment shown includes a cabinet 1, the top of the cabinet 1 is provided with an input port 11, and the bottom of the cabinet 1 is provided with a film outlet 12, and the film outlet 12 corresponds to the input port 11, the two sides of the film outlet 12 are set as an arc-shaped bottom chamber 13, and the arc-shaped bottom chamber 13 stores the processing liquid. The inside of the cabinet 1 is symmetrically provided with two groups of crushing mechanisms, and the crushing mechanisms include Rotate the crushing roller 2 installed inside the cabinet 1, the two groups of crushing rollers 2 mesh with each other, the end of the crushing roller 2 is rotatably installed with a pendulum 3, and the inner wall of one side of the cabinet 1 is rotatably installed with two sets of drive Fork 4, two groups of said driving fork 4 are rotated and driven by external drive eq...

Embodiment 3

[0040] Based on Example 1, the difference is that, as Figure 1-3 A liquid crystal glass waste crushing and recycling equipment shown includes a cabinet 1, the top of the cabinet 1 is provided with an input port 11, and the bottom of the cabinet 1 is provided with a film outlet 12, and the film outlet 12 corresponds to the input port 11, the two sides of the film outlet 12 are set as an arc-shaped bottom chamber 13, and the arc-shaped bottom chamber 13 stores the processing liquid. The inside of the cabinet 1 is symmetrically provided with two groups of crushing mechanisms, and the crushing mechanisms include Rotate the crushing roller 2 installed inside the cabinet 1, the two groups of crushing rollers 2 mesh with each other, the end of the crushing roller 2 is rotatably installed with a pendulum 3, and the inner wall of one side of the cabinet 1 is rotatably installed with two sets of drive Fork 4, two groups of said driving fork 4 are rotated and driven by external drive eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com