Shielded cable recovery processing equipment

A technology for shielded cables and processing equipment, applied in the field of shielded cable recycling and processing equipment, can solve the problems of cumbersome and complicated processing procedures of shielded cables, inability to achieve stripping, and high processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

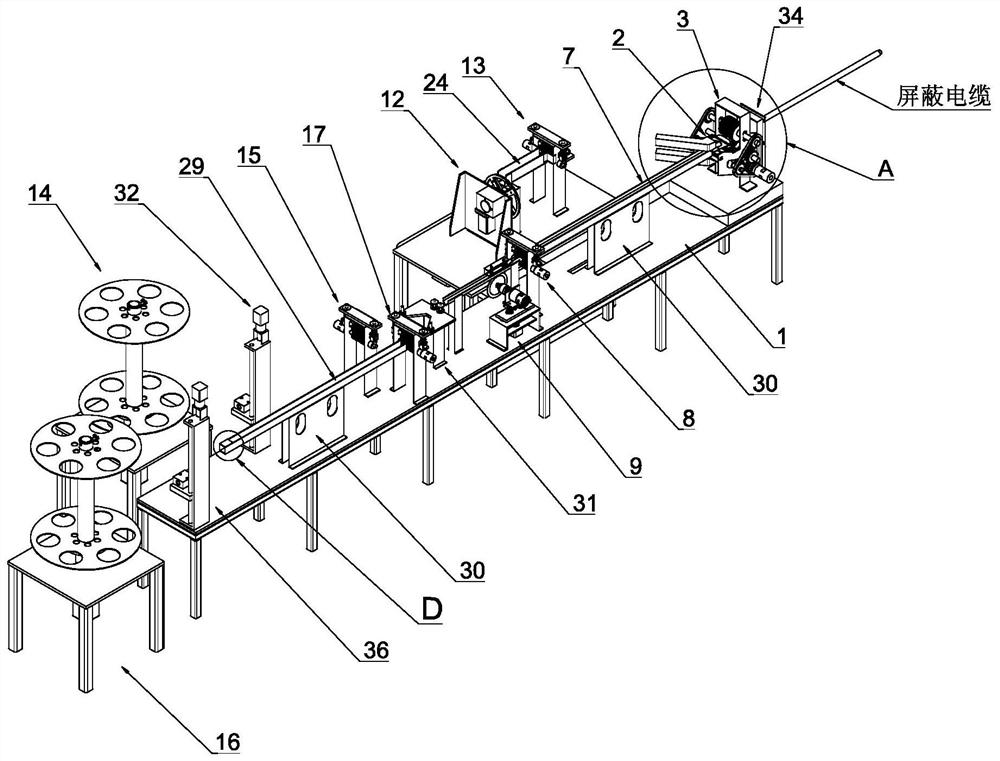

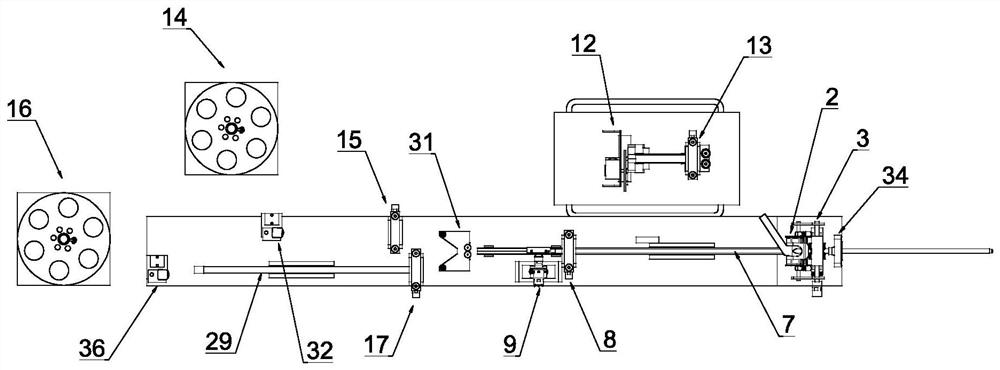

[0060] see Figure 1-Figure 2 , this embodiment discloses a shielded cable recycling and processing equipment, comprising a chassis 1, a coating layer stripping device arranged at the front end of the chassis 1, a shielding layer stripping device arranged at the rear end of the chassis 1, and a Covering layer recycling device, shielding layer recycling device and core recycling device.

[0061] see Figure 1-Figure 2 , the covering layer stripping device includes a covering layer peeling mechanism 2 arranged on the chassis 1 for peeling off the covering layer of the shielded cable, and a covering layer stripping mechanism 2 arranged on the chassis 1 for transporting the shielded cable to the covering layer The first conveying drive mechanism 3 of the peeling mechanism 2 .

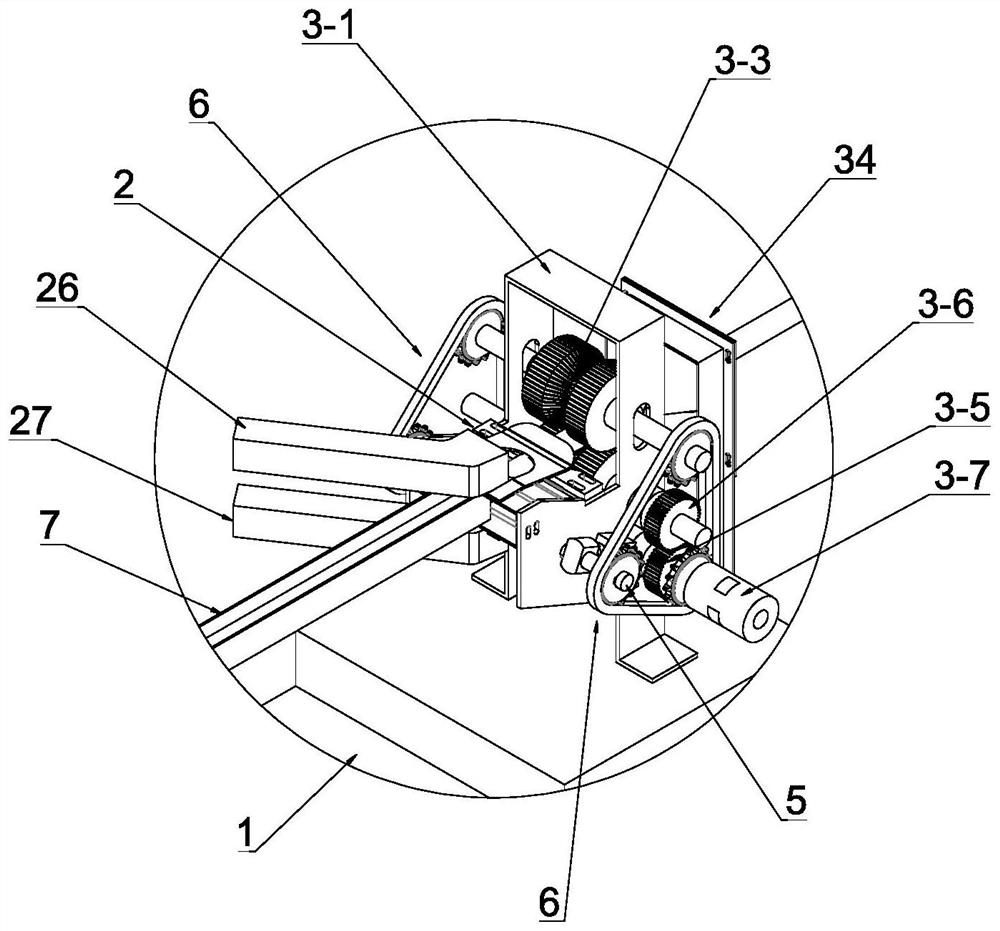

[0062] see Figure 1-Figure 9 , the first conveying drive mechanism 3 includes a first gantry 3-1 arranged on the chassis 1 and a first roller mechanism arranged on the first gantry 3-1 for driving the shi...

Embodiment 2

[0104] Other structures in this embodiment are the same as in Embodiment 1, except that the elastic pressing mechanism in this embodiment can use the adaptive pressing assembly 23 in Embodiment 1 to realize the adaptive pressing of the first roller mechanism Features.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com