Printing laminating equipment

A technology for lamination and equipment, applied in the field of printing lamination equipment, can solve the problems of difficult integration of multiple processes, increase processing costs, and use more power sources, and achieve the advantages of reducing processing costs, fast printing and cutting, and improving practicability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

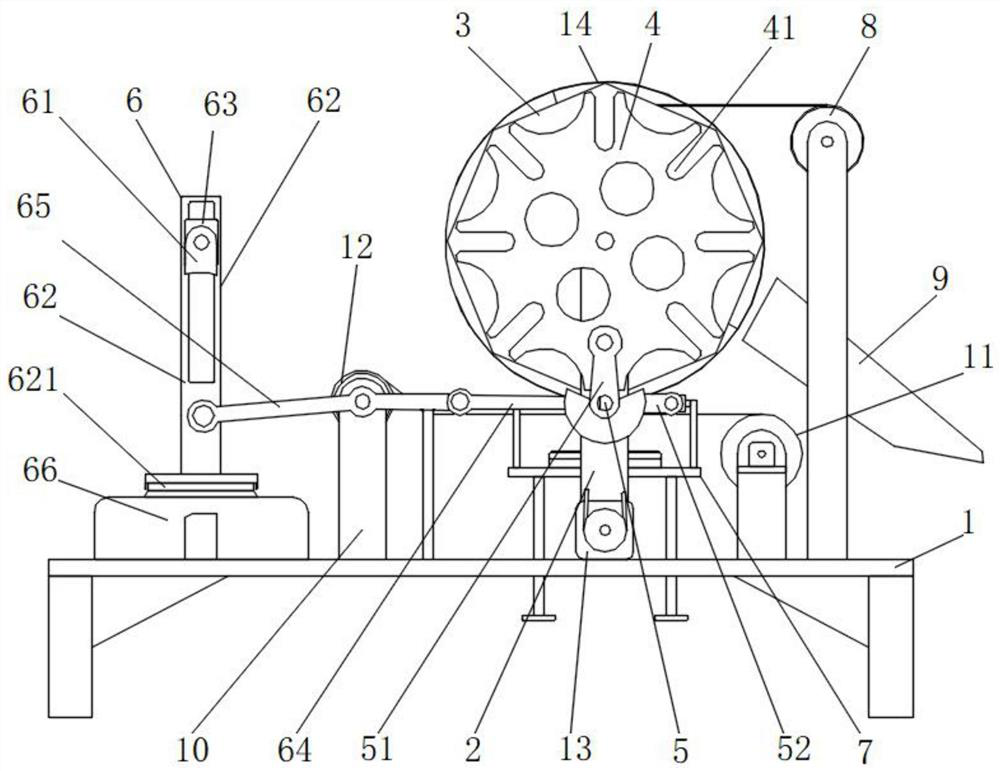

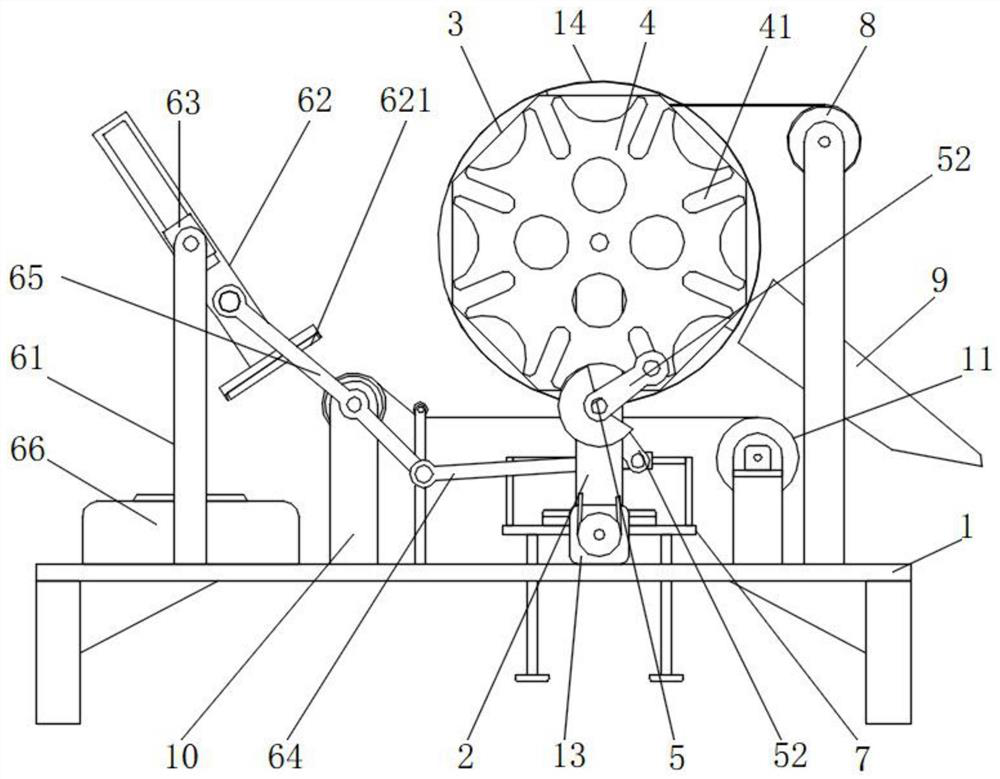

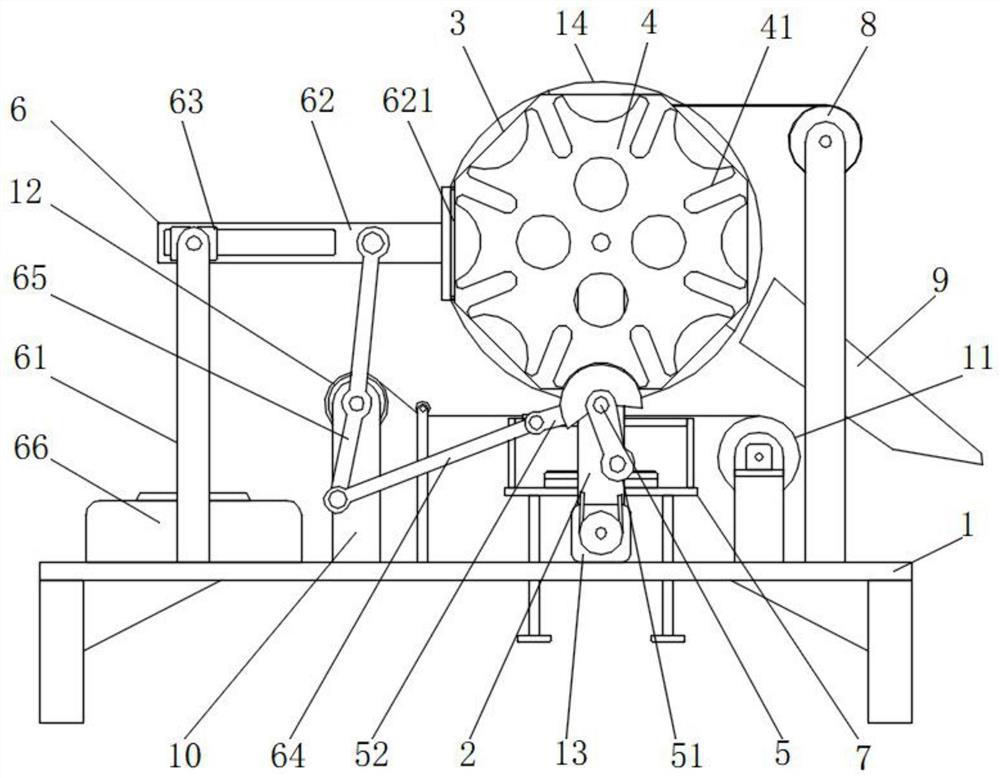

[0030] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0031] The present invention provides such Figure 1-9A kind of printing laminating equipment shown, comprises base 1, and the top of described base 1 is fixedly installed with first shelf board 2, and the inside of the top of described first shelf board 2 is connected with octahedral cylinder 3, and the eight sides One end of the face cylinder 3 is fixedly connected with a spacer control plate 4 through a rotating shaft, and the spacer control plate 4 is located on the outside of the first frame plate 2, and eight spacer grooves 41 are provided on the circumferential side of the spacer control plate 4. The middle part of the first frame plate 2 is rotatably connected with a drive shaft 5, and the drive shaft 5 is positioned at the bottom of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com