Mould roller for brightening film forming and manufacturing method thereof

A mold roll and steel roll technology, applied in the coating and other directions, can solve the problems of large diamond tool wear, high hardness of nickel-plated mold rolls, UV glue residue, etc., to achieve the effects of low cost, difficult to hang glue, and easy processing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

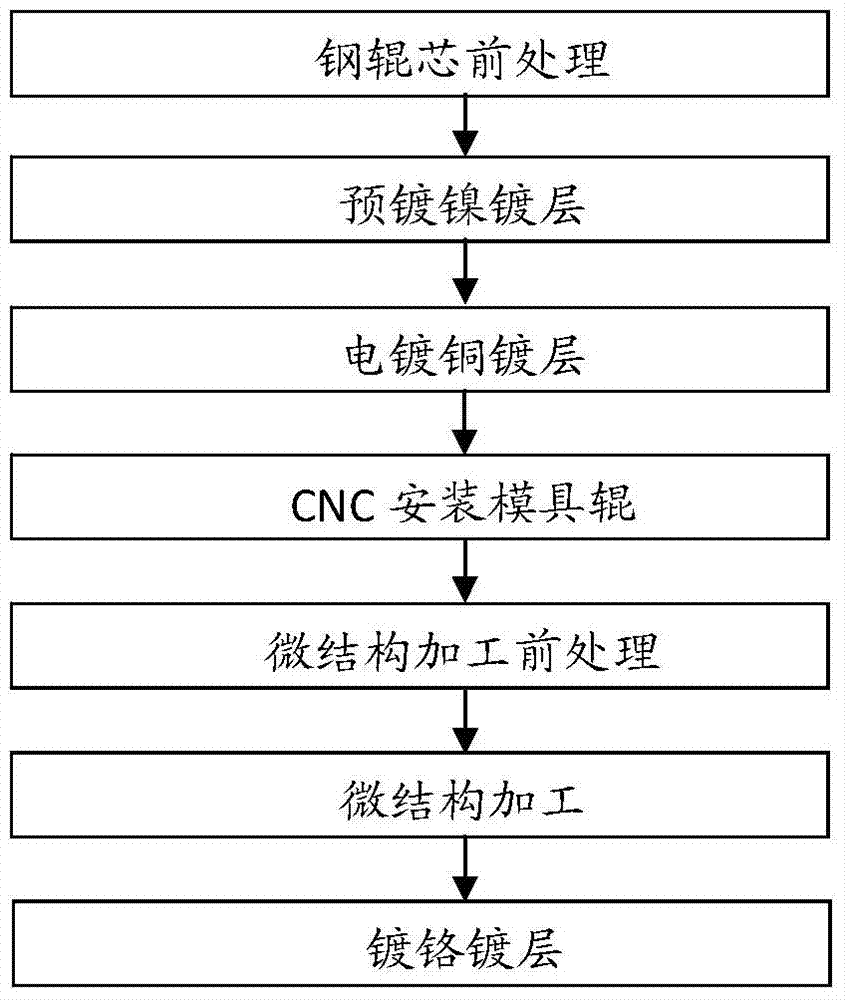

[0058] Such as figure 2 Shown, the preparation method of mold roll provided by the invention may further comprise the steps:

[0059] (1) Pre-treatment of the steel roller core: Before electroplating the processed steel roller core, it is necessary to clean the surface to ensure that the electroplating layer adheres well and does not peel. First use a special metal cleaning agent to remove surface oil and other sundries, then rinse with water, and finally activate the surface of the roller core with 3%-5% dilute sulfuric acid.

[0060] (2) Pre-plating nickel layer: In the case of no current, the steel roller core will undergo a displacement reaction when it contacts the acidic copper plating solution, and a layer of chemically replaced copper on the surface will be obtained, which is not firmly bonded to the surface of the steel roller core. Therefore, copper plating cannot be performed directly after cleaning, but a layer of nickel with a thickness of 8 μm to 10 μm must be ...

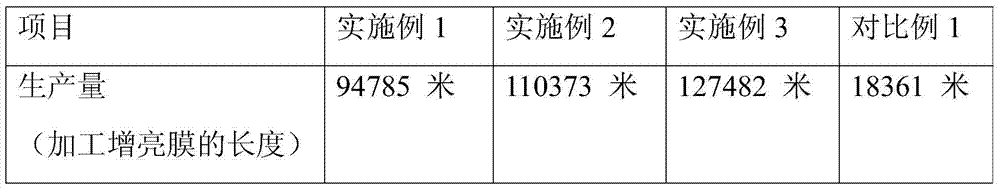

Embodiment 1

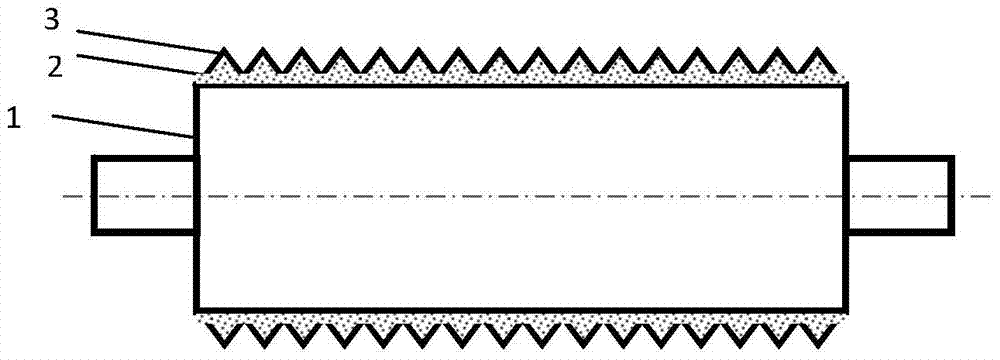

[0067] The invention provides a mold roll, which comprises a steel roll core, the surface of the steel roll core is pre-plated with a nickel coating with a thickness of 8 μm, and a copper coating with a thickness of 350 μm is arranged on the surface of the nickel coating, and the copper coating is A prism structure is engraved on the top, and a chromium plating layer is arranged on the surface of the prism structure; the hardness of the copper plating layer is HV230; the thickness of the chromium plating layer is 1 μm, and the hardness of the chromium plating layer is HV820.

[0068] The preparation method of above-mentioned mold roll, comprises the steps:

[0069] (1) Pretreatment of the steel roller core: Use a special metal cleaning agent to remove surface oil and other sundries, then rinse with clean water, and finally activate the surface of the roller core with 4% dilute sulfuric acid.

[0070](2) Pre-plating bottom layer: the nickel-plated anode is an electrolytic nicke...

Embodiment 2

[0077] As in the mold roll provided in Example 1, the thickness of the nickel coating is 10 μm, the thickness of the copper coating is 1000 μm, and the hardness of the copper coating is HV280; the thickness of the chromium coating is 5 μm, and the hardness of the chromium coating is HV970.

[0078] The preparation method of mold roll as provided in embodiment 1, wherein,

[0079] (2) Pre-plated bottom layer: the nickel-plated anode is an electrolytic nickel plate, and the main components of the nickel-plating solution include 320g / L of nickel sulfate, 45g / L of nickel chloride as an anode activator, and 50g / L of boric acid as a buffer. Stabilize the pH of the plating solution at 4.2, adjust it with NaOH, use 2ml / L hydrogen peroxide as an anti-pinhole agent, and control the temperature of the plating solution at 40±1°C, using 3A / dm 2 Plating current of 20 minutes was carried out to obtain a pre-plated nickel layer;

[0080] (3) Thick copper plating: After plating the bottom lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com