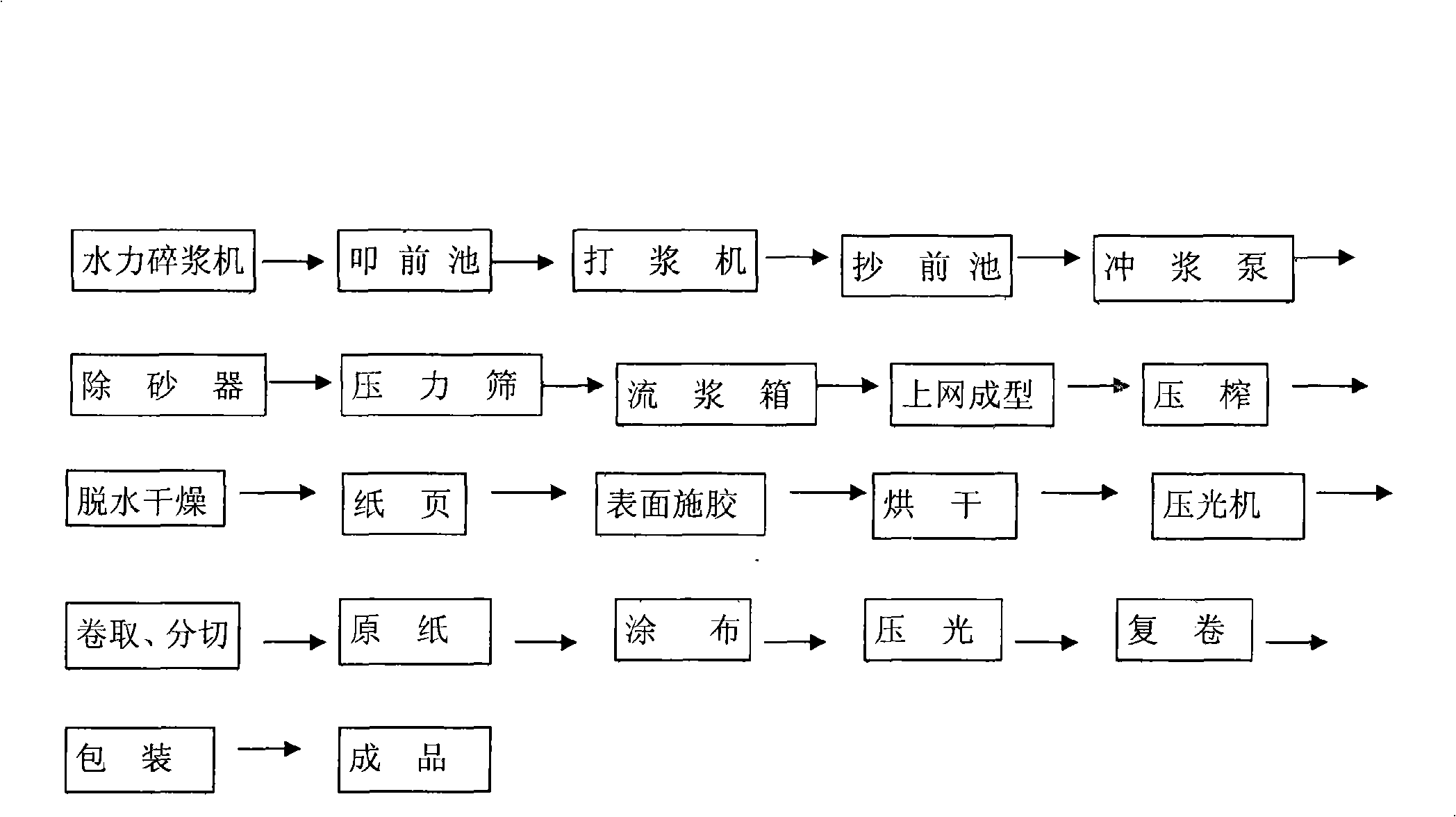

Paper making process for precoating water transfer printing base paper

A papermaking process, water transfer printing technology, applied in papermaking, papermaking, textiles and papermaking, etc., can solve the problems of unclear printing patterns, dependence on imports, rough surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Add 2800kg of clear water and 200kg of denatured oxidized starch to the glue pot, stir evenly, slowly heat up and boil, when the temperature rises to 98°C, keep it warm for 15 minutes, then cool down to 69°C, stir evenly, filter to obtain a surface sizing solution, and set aside .

[0033] Pulping is pulverized by a hydraulic pulper, with 2.6mm bleached kraft softwood long-fiber wood pulp and short-fiber wood pulp with a fiber length of 1.1mm bleached kraft softwood, and the weight ratio is long-fiber wood pulp: short Fiber wood pulp = 3:7, pulverized by a hydropulper, adding a charge enhancer with a concentration of 14% when pulping, and the amount per ton of paper is 10kg, transferred to the pre-knock pool, passed through a double-disc mill beater, beating, current 380A, The beating concentration is 4.0%, the beating degree is 23°SR, and the slurry is prepared, and then the wet strength agent with a concentration of 1.0% is added, and the amount of paper per ton is 10...

Embodiment 2

[0038] Add 2900kg of clear water and 190kg of denatured oxidized starch to the glue pot, stir evenly, slowly heat up and boil, when the temperature rises to 100°C, keep it warm for 16 minutes, and then cool down to 70°C to prepare a surface sizing solution for later use;

[0039] Pulping is pulverized by a hydraulic pulper, with 2.7mm bleached kraft softwood long-fiber wood pulp and short-fiber wood pulp with a fiber length of 1.2mm bleached kraft softwood, and the weight ratio is long-fiber wood pulp: short Fiber wood pulp = 2:8, pulverized by a hydraulic pulper, adding a charge enhancer with a concentration of 15% when pulping, and the amount of paper per ton is 11kg, transferred to the pre-knock pool, and beaten by a double-disc mill beater with a current of 390A , the beating concentration is 3.9%, and the beating degree is 24°SR. After obtaining the pulp, add a wet strength agent with a concentration of 0.95%, and the amount of paper per ton is 110kg. Mix evenly, pass thr...

Embodiment 3

[0044] Add 2800kg of clear water and 210kg of denatured oxidized starch to the glue pot, stir evenly, slowly heat up and boil, when the temperature rises to 105°C, keep it warm for 18 minutes, then cool down to 75°C, stir evenly, filter to obtain a surface sizing solution, spare.

[0045] Pulping is pulverized by a hydraulic pulper, with 2.6mm bleached kraft softwood long-fiber wood pulp and short-fiber wood pulp with a fiber length of 1.0mm bleached kraft softwood, and the weight ratio is long-fiber wood pulp: short Fiber wood pulp = 2:8, pulverized by a hydropulper, adding a charge enhancer with a concentration of 15% when pulping, and the amount per ton of paper is 12kg, transferred to the pre-knock pool, passed through a double-disc mill beater, beating, current 400A, The beating concentration is 4.3%, the beating degree is 25°SR, and the pulp is prepared, and then the wet strength agent with a concentration of 1.1% is added, and the amount of paper per ton is 100kg. Stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com