Antiflaming floor and manufacture method thereof

A manufacturing method and floor technology, applied in chemical instruments and methods, building structures, buildings, etc., can solve the problems of low combustion performance level, high production cost, inability to prevent moisture, etc., and achieve good flame retardant effect, good glue connection, The effect of a high level of flame resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

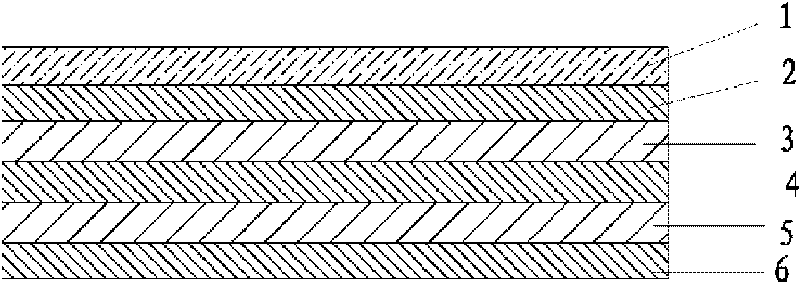

[0033] Such as figure 1 As shown, this embodiment is a kind of flame-retardant floor, which is decorative layer 1, veneer layer 2, flame-retardant layer 3, second veneer layer 4, second flame-retardant layer 5, and third single-layer layer from outside to inside. The board layers 6 are connected to each other by adhesives, and the decoration layer and the veneer layer can be prepared by the existing technology. Different from the existing floor, the flame-retardant floor of the present invention adds two layers of flame-retardant layers between the multi-layer veneer layers to isolate them. The flame retardant layer is made of glass magnesium board. Each ply adhesive can be polyurethane or acrylic or rubber.

[0034] The above-mentioned flame-retardant floor is manufactured by the following method, which includes the following steps in turn:

[0035] a. Prepare the decorative layer, veneer layer and flame retardant layer;

[0036] b. Sizing the veneer layers prepared above...

Embodiment 2

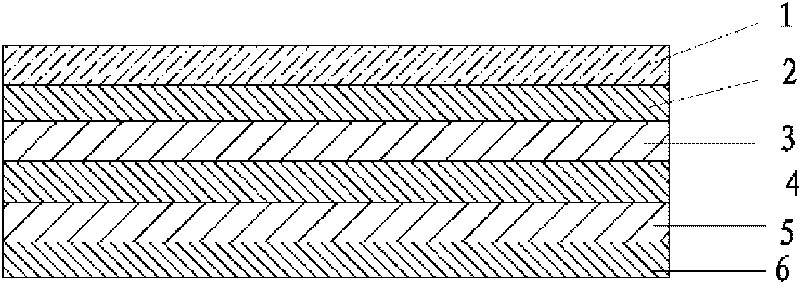

[0043] This embodiment is a kind of flame-retardant floor, which is decorative layer 1, veneer layer 2, flame-retardant layer 3, second veneer layer 4, second flame-retardant layer 5, and third veneer layer 6 from outside to inside. Each layer is connected to each other through an adhesive, wherein the decorative layer and the veneer layer can be prepared by using the existing prior art. Different from the existing floor, the flame-retardant floor of the present invention adds a flame-retardant layer separating them between the multi-layer veneer layers. The flame retardant layer consists of calcium silicate boards. The adhesive can be polyurethane or acrylic or rubber.

[0044] The above-mentioned flame-retardant floor is manufactured by the following method, which includes the following steps in turn:

[0045] a. Prepare the decorative layer, veneer layer and flame retardant layer;

[0046] b. Sizing the veneer layers prepared above, aging after sizing, and then forming a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com