Thermal treatment process for high-strength anticorrosion aluminum alloy

A corrosion-resistant and alloyed technology, applied in the field of heat treatment of aluminum alloy materials, can solve problems such as discontinuous distribution, poor corrosion resistance, and strength decline, and achieve the effects of prolonging the regression time, simplifying the operation process, and reducing the regression temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

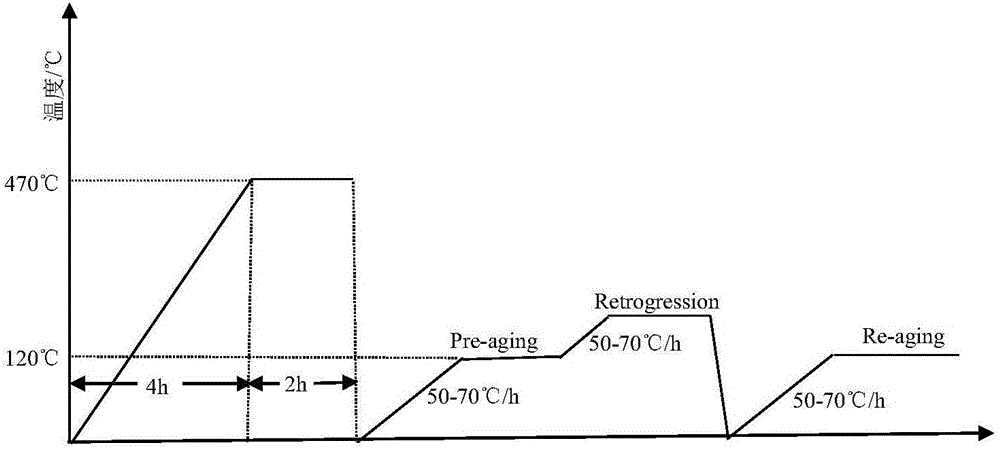

[0029] The Al-7.2Zn-2.3Mg-0.6Cu-0.3Mn-0.1Er-0.1Zr alloy after hot extrusion deformation was raised from room temperature to 470 °C for 4 hours, then kept for 2 hours, and then water quenched immediately; then aging heat treatment was performed , the first-stage aging heat treatment process is to increase the alloy obtained after solution-water quenching from room temperature to 120 °C at a heating rate of 50-70 °C / h, and then keep it for 24 hours; the second-stage heat treatment process is the first-stage aging. The obtained alloy is directly heated from 120°C to 190°C at a heating rate of 50-70°C / h in the furnace, then kept for 40 minutes, and then cooled to room temperature; the third-stage heat treatment process is that the alloy obtained after the second-stage heat treatment is The heating rate of 50-70°C / h was raised from room temperature to 120°C, then kept for 24h, and then cooled to room temperature. After aging treatment, exfoliation corrosion and tensile properties w...

Embodiment 2

[0031] The Al-7.2Zn-2.3Mg-0.6Cu-0.3Mn-0.1Er-0.1Zr alloy after hot extrusion deformation was raised from room temperature to 470 °C for 4 hours, then kept for 2 hours, and then water quenched immediately; then aging heat treatment was performed , the first-stage aging heat treatment process is to increase the alloy obtained after solution-water quenching from room temperature to 120 °C at a heating rate of 50-70 °C / h, and then keep it for 24 hours; the second-stage heat treatment process is the first-stage aging. The obtained alloy is directly heated from 120°C to 190°C with a heating rate of 50-70°C / h in the furnace, then kept for 60 minutes, and then cooled to room temperature; the third-stage heat treatment process is that the alloy obtained after the second-stage heat treatment is The heating rate of 50-70°C / h was raised from room temperature to 120°C, then kept for 24 hours, and then cooled to room temperature. After aging treatment, exfoliation corrosion and tensile prope...

Embodiment 3

[0033]Heat the Al-7.2Zn-2.3Mg-0.6Cu-0.3Mn-0.1Er-0.1Zr alloy after hot extrusion deformation from room temperature to 470°C in 4 hours, then keep it warm for 2 hours, and immediately perform water quenching; then perform aging heat treatment , the first-stage aging heat treatment process is to raise the alloy obtained after solid solution-water quenching from room temperature to 120°C at a rate of 50-70°C / h, and then keep it for 24h; the second-stage heat treatment process is the first-stage aging The processed alloy is directly raised from 120°C to 180°C at a heating rate of 50-70°C / h with the furnace, then kept for 60 minutes, and then cooled to room temperature; the third-level heat treatment process is the alloy obtained after the second-level heat treatment. The heating rate was 50-70°C / h from room temperature to 120°C, then kept for 24 hours, and then cooled to room temperature. After aging treatment, exfoliation corrosion and tensile performance tests were carried out ac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com