Polyurethane cement mortar and preparation method thereof

A cement mortar and polyurethane technology, used in building materials and chemical fields, can solve the problems of large shrinkage deformation, impermeability, poor crack resistance and corrosion resistance, high density, etc., and achieve high elongation and small volume shrinkage. , The effect of strong anti-deformation ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

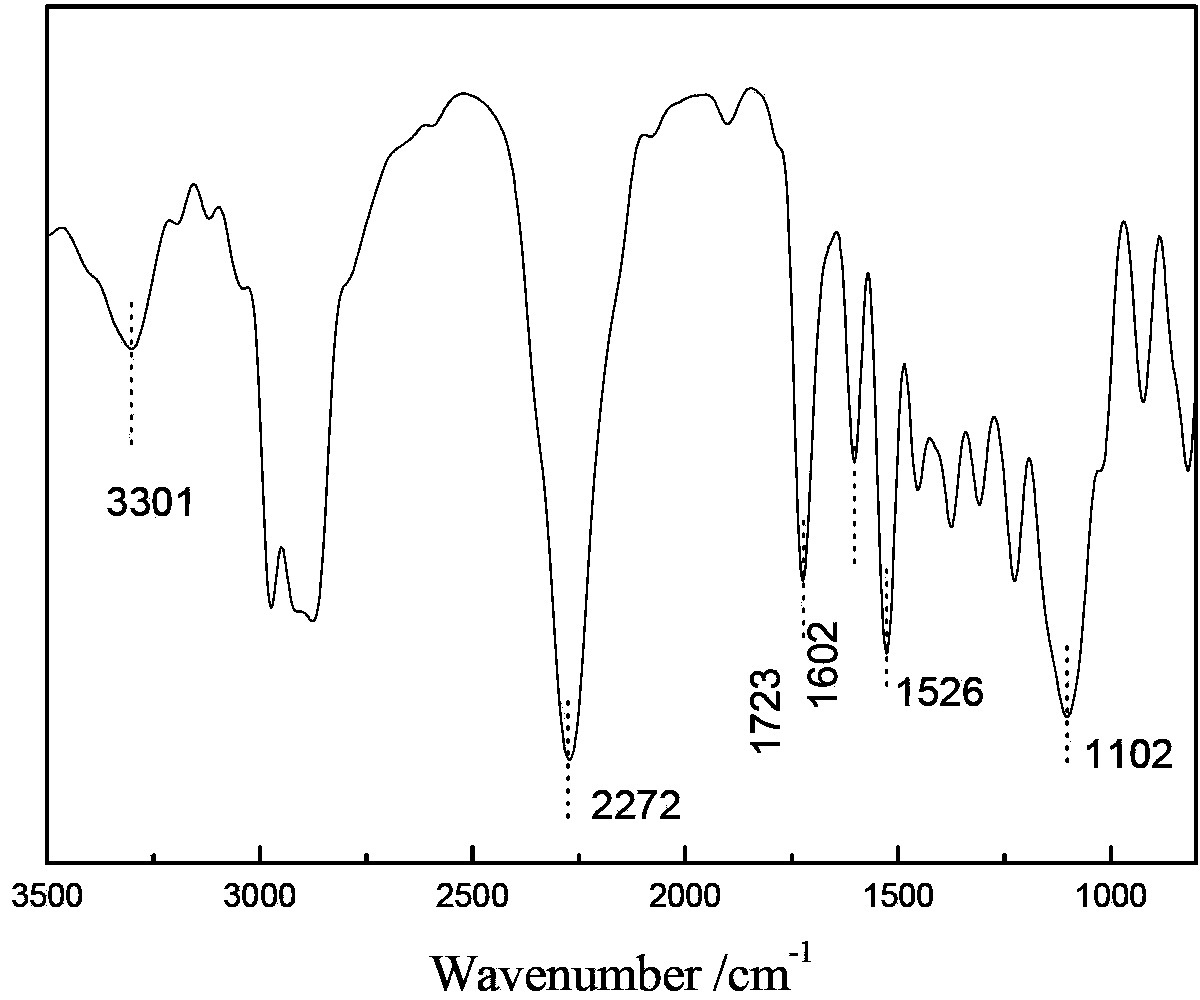

Image

Examples

Embodiment 1

[0023] The polyurethane cement mortar of this embodiment comprises, by weight, 50 parts of Portland cement, 100 parts of 30-150 mesh fine sand, 10 parts of water, 1.5 parts of calcium formate, 0.9 part of sulfonated melamine formaldehyde, and 20 parts of one-component polyurethane The one-component polyurethane includes isocyanate, polyether 220, polyether 330, catalyst and solvent, and the molar ratio of isocyanate: polyether 220: polyether 330: catalyst: solvent is 4:1:2:0.0045:20.

[0024] The isocyanate in this embodiment is polymethylene polyphenyl polyisocyanate PAPI.

[0025] The method that present embodiment prepares polyurethane cement mortar, comprises the following steps:

[0026] (1) Heat polyether 220 and polyether 330 to 110°C, dehydrate under 0.06MPa vacuum for 2 hours, and when the mass fraction of polyether moisture is measured to be below 0.05%, cool down to 40°C to obtain a dehydrated mixed polyether ;

[0027] (2) Slowly add PAPI to the dehydrated mixed ...

Embodiment 2

[0034] The polyurethane cement mortar of this embodiment, by weight, includes 70 parts of sulfoaluminate cement, 140 parts of fine sand of 30-150 mesh, 35 parts of water, 6 parts of early strength agent, 2.4 parts of water reducing agent, one-component polyurethane 25 parts; the one-component polyurethane includes isocyanate, polyether 220, polyether 330, catalyst and solvent, and the molar ratio of isocyanate: polyether 220: polyether 330: catalyst: solvent is 2:3:3:0.0015:16 .

[0035] The method that present embodiment prepares polyurethane cement mortar, comprises the following steps:

[0036] (1) Heat polyether 220 and polyether 330 to 120°C, dehydrate under 0.08MPa vacuum for 3 hours, and when the measured polyether moisture content is below 0.05%, cool down to 50°C to obtain a dehydrated mixed polyether ;

[0037] (2) Slowly add liquefied MDI into the dehydrated mixed polyether prepared in step (1), under the protection of nitrogen, add the catalyst dibutyltin dilaura...

Embodiment 3

[0043] The polyurethane cement mortar of this embodiment comprises, by weight, 60 parts of sulfate cement, 120 parts of 30-150 mesh fine sand, 25 parts of water, 3 parts of early strength agent, 1.6 parts of water reducing agent, and 22 parts of one-component polyurethane The one-component polyurethane includes isocyanate, polyether 220, polyether 330, catalyst and solvent, and the molar ratio of isocyanate: polyether 220: polyether 330: catalyst: solvent is 3:2:2.5:0.003:18.

[0044] The method that present embodiment prepares polyurethane cement mortar, comprises the following steps:

[0045] (1) Heat polyether 220 and polyether 330 to 115°C, dehydrate under 0.07MPa vacuum for 2.5 hours, and when the mass fraction of polyether moisture is measured to be below 0.05%, cool down to 45°C to obtain a dehydrated mixed poly ether;

[0046] (2) Slowly add toluene diisocyanate into the dehydrated mixed polyether prepared in step (1), under the protection of nitrogen, drop in the cat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com