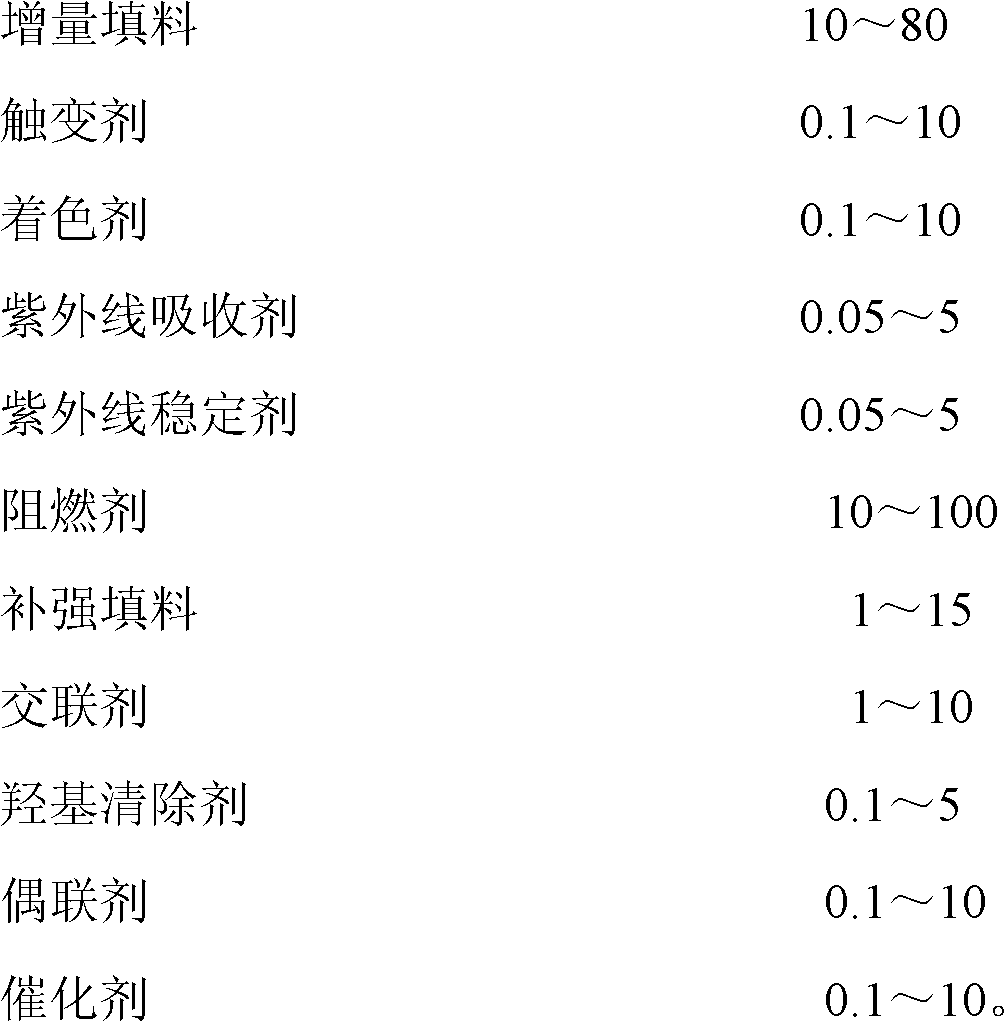

Monocomponent flame-retardant silane modified polyether sealant and preparation method thereof

A silane-modified polyether, flame-retardant technology, applied in the direction of polyether adhesives, adhesives, adhesive types, etc., can solve the problems of slow curing speed at low temperature, easy aging and hardening, erosion, etc. Good effect, high weather resistance, fast curing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

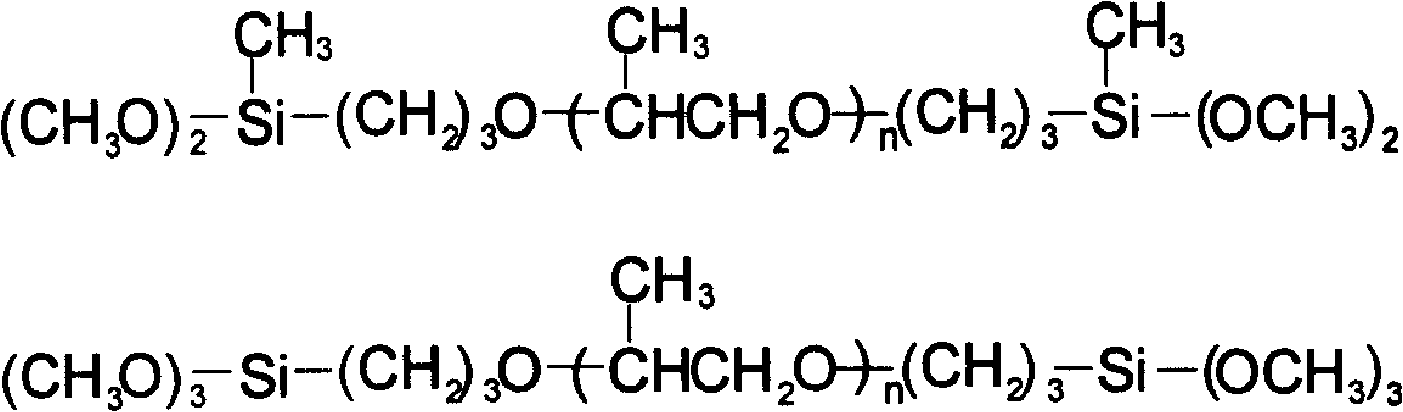

Method used

Image

Examples

Embodiment 1

[0032] The present invention will be further described below using specific examples. In the implementation, all are in parts by weight.

[0033]

[0034] Wherein, in terms of platinum content, a platinum complex compound accounting for 20 parts per million of the total weight of raw materials is also added, and the platinum complex compound is obtained by reacting divinyltetramethoxydisiloxane and chloroplatinic acid. (Karstedtd 322 produced by Heraeus (Heraeus) used in the present invention)

[0035] During preparation, add MS-polymer, methyl silicone oil, ultraviolet absorber and stabilizer sequentially to the vacuum kneader at room temperature, and blend for 10 to 15 minutes under vacuum protection; then add nano-calcium carbonate in batches, gas phase method Mix white carbon black, aluminum hydroxide, basic zinc carbonate, polyamide thixotropic agent and titanium dioxide for 10-15 minutes under vacuum protection; raise the temperature to 150°C, vacuum blend for 1-2hr;...

Embodiment 2

[0046] The present invention will be further described below using specific examples. In the implementation, all are in parts by weight.

[0047]

[0048] Wherein, in terms of platinum content, a platinum complex compound accounting for 20 parts per million of the total weight of raw materials is also added, and the platinum complex compound is obtained by reacting divinyltetramethoxydisiloxane and chloroplatinic acid. (Heraeus Karstedtd 322)

[0049] The preparation method is the same as in Example 1.

Embodiment 3

[0051] The present invention will be further described below using specific examples. In the implementation, all are in parts by weight.

[0052]

[0053] Wherein, in terms of platinum content, a platinum complex compound accounting for 20 parts per million of the total weight of raw materials is also added, and the platinum complex compound is obtained by reacting divinyltetramethoxydisiloxane and chloroplatinic acid. (Heraeus Karstedtd 322)

[0054] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com