Quick formwork erecting construction method for cast-in-place wave wall

A construction method and technology of a wave wall, applied in the direction of breakwaters, coastline protection, jetties, etc., can solve the problems of increasing project investment and labor intensity of workers, increasing invalid construction time, and large safety hazards of scaffolding, so as to save linear construction period and reduce The labor intensity of workers and the effect of shortening the construction period of the project

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

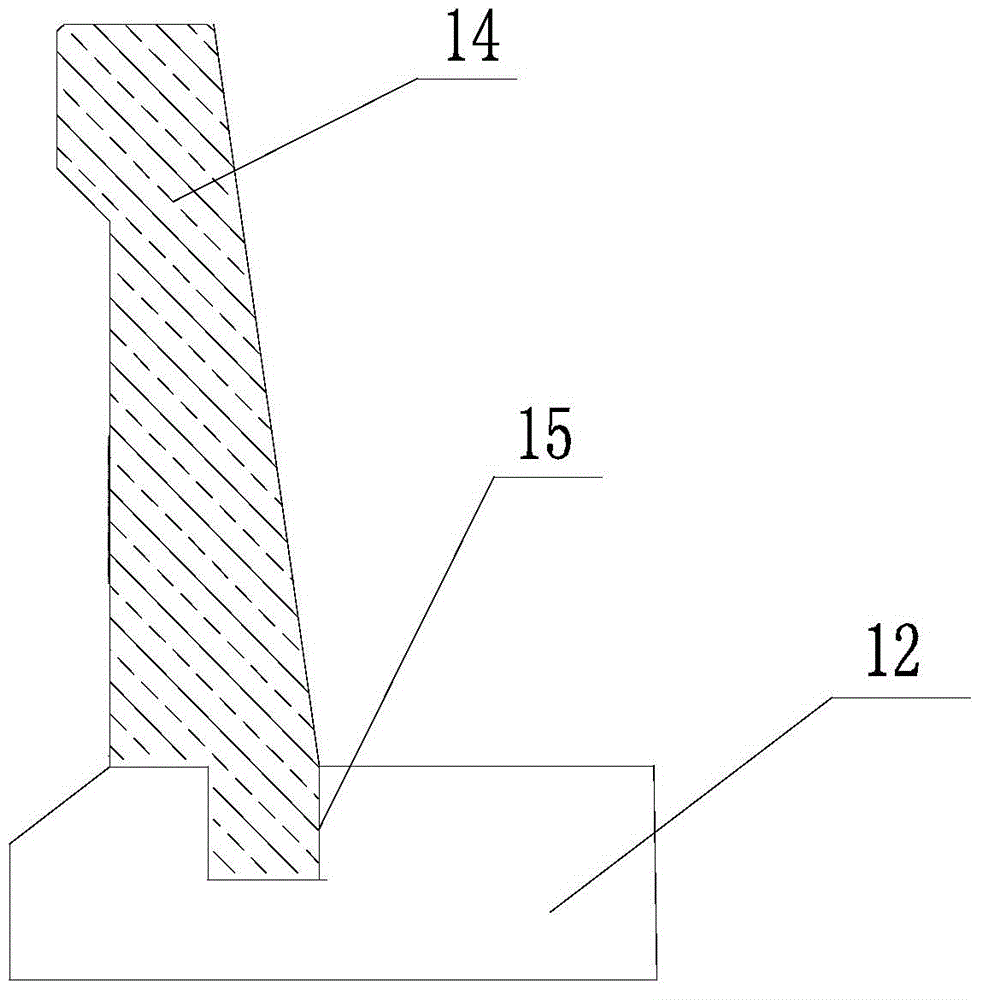

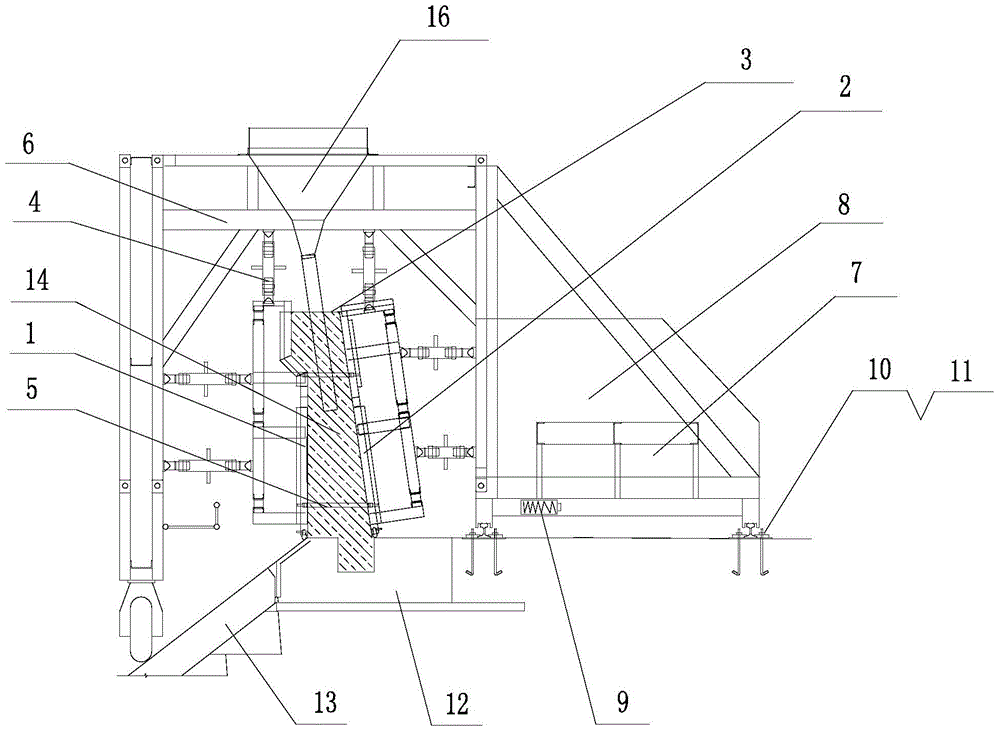

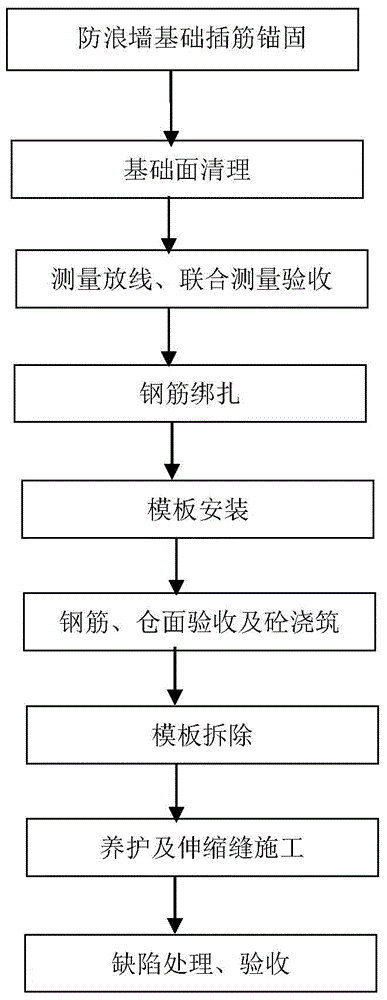

[0034] The present invention uses a special pouring device "self-propelled hydraulic cantilever gantry type anti-wave wall concrete pouring device (patent application number CN201020648386)" to fully and quickly perform formwork and demolition of the anti-wave wall pouring, refer to figure 1 , the pouring device consists of a trolley, traction device, shaped formwork system and support system. The trolley includes a door frame 6, screw rod braces, an operating platform, a counterweight platform 8 and a walking mechanism. The shaped formwork system is based on the concrete pouring structure. It is determined that it is composed of upstream side formwork 1, downstream side formwork 2 and end formwork 3, and is suspended and connected to the door frame 6 through hydraulic support rods 4, and the electric hoist 9 of the traction device is installed under the front edge of the counterweight platform 8 . The counterweight platform 8 is provided with concrete counterweight blocks 7 ,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com