Composite beam and composite beam and column joint connecting device

A technology of connecting device and composite beam, applied in the direction of joists, girders, truss beams, etc., can solve the problems of unbalanced force at the joint, weak connection of beams and columns, and easy damage of connecting screws, etc., to achieve balanced force, Good anti-corrosion performance and the effect of reducing load-bearing pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

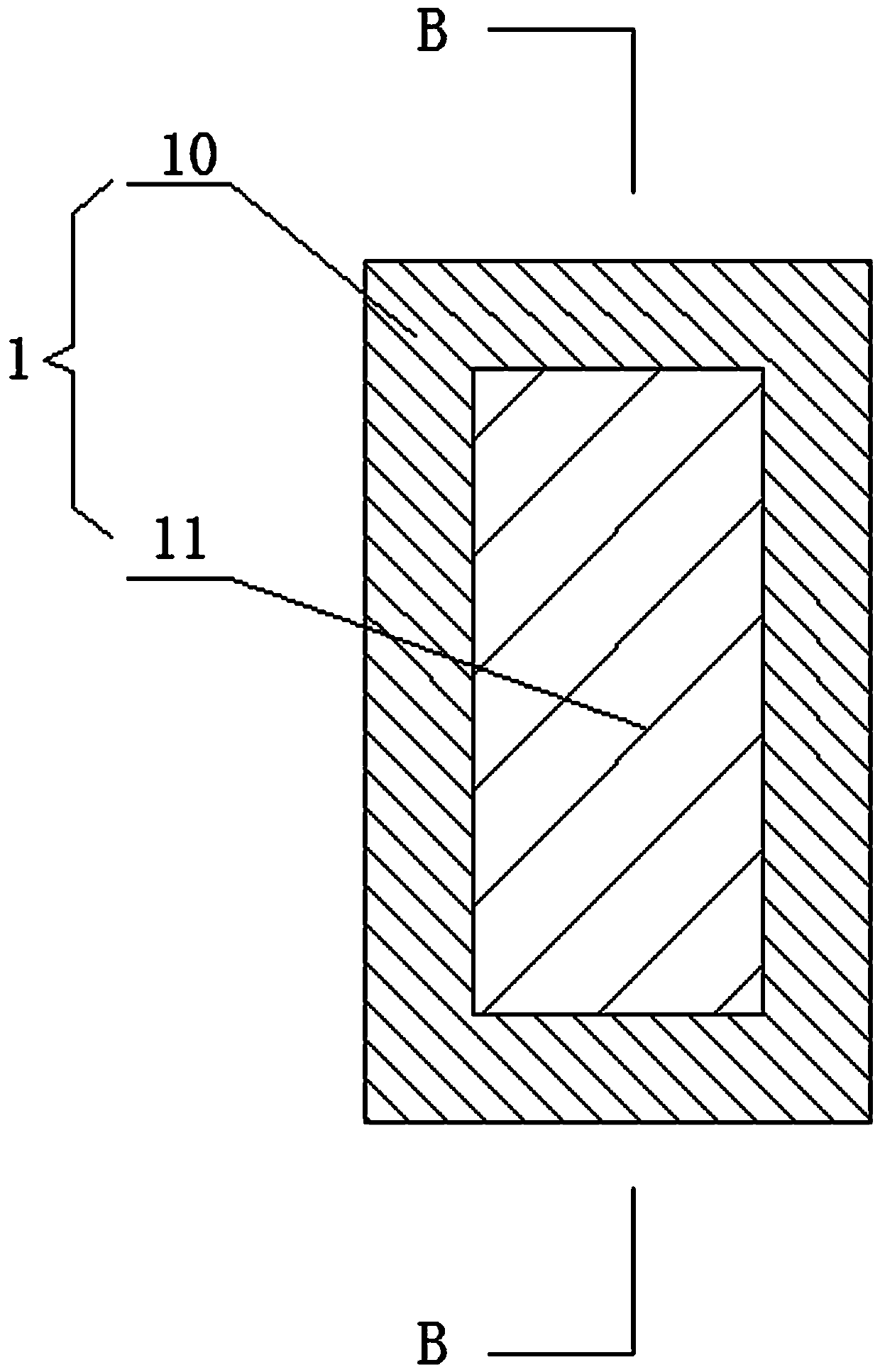

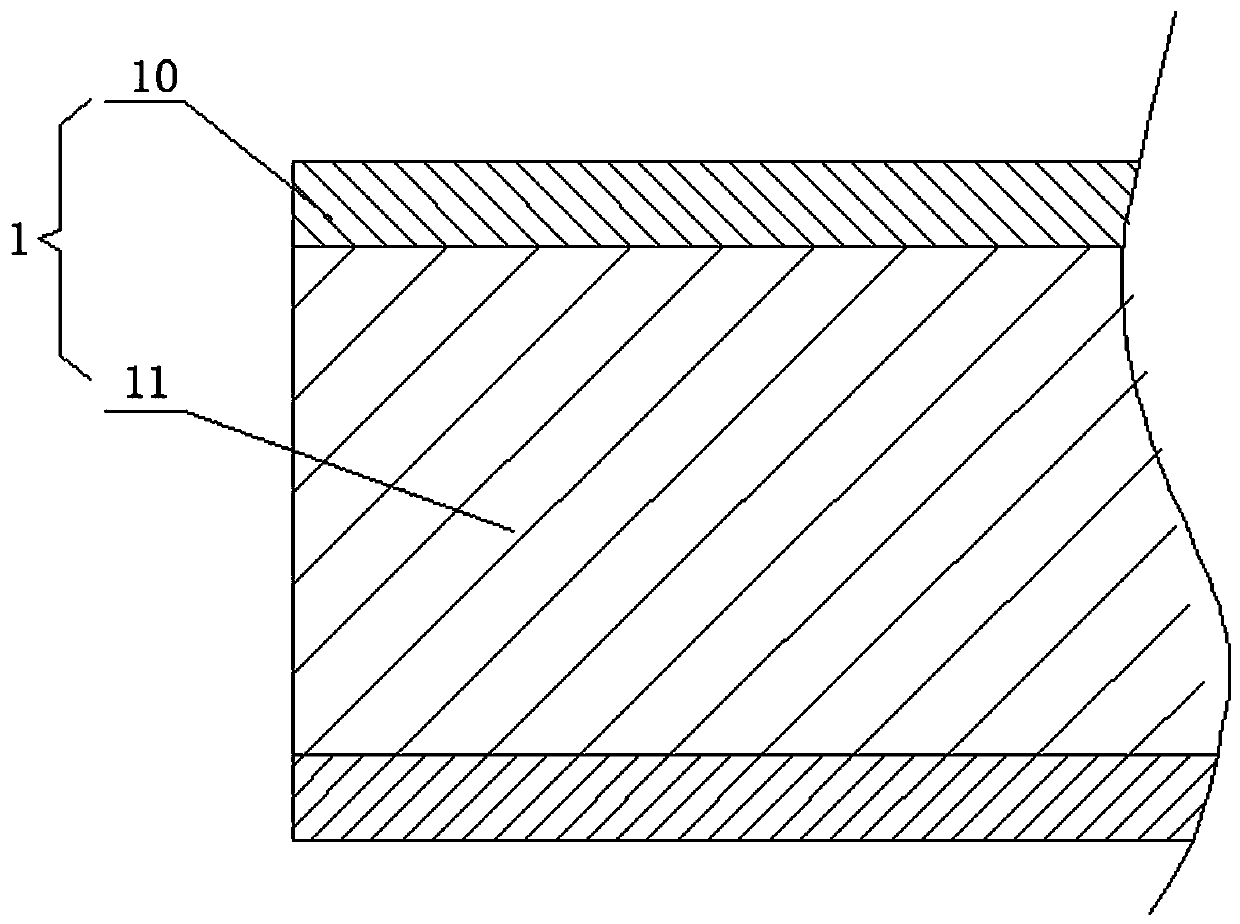

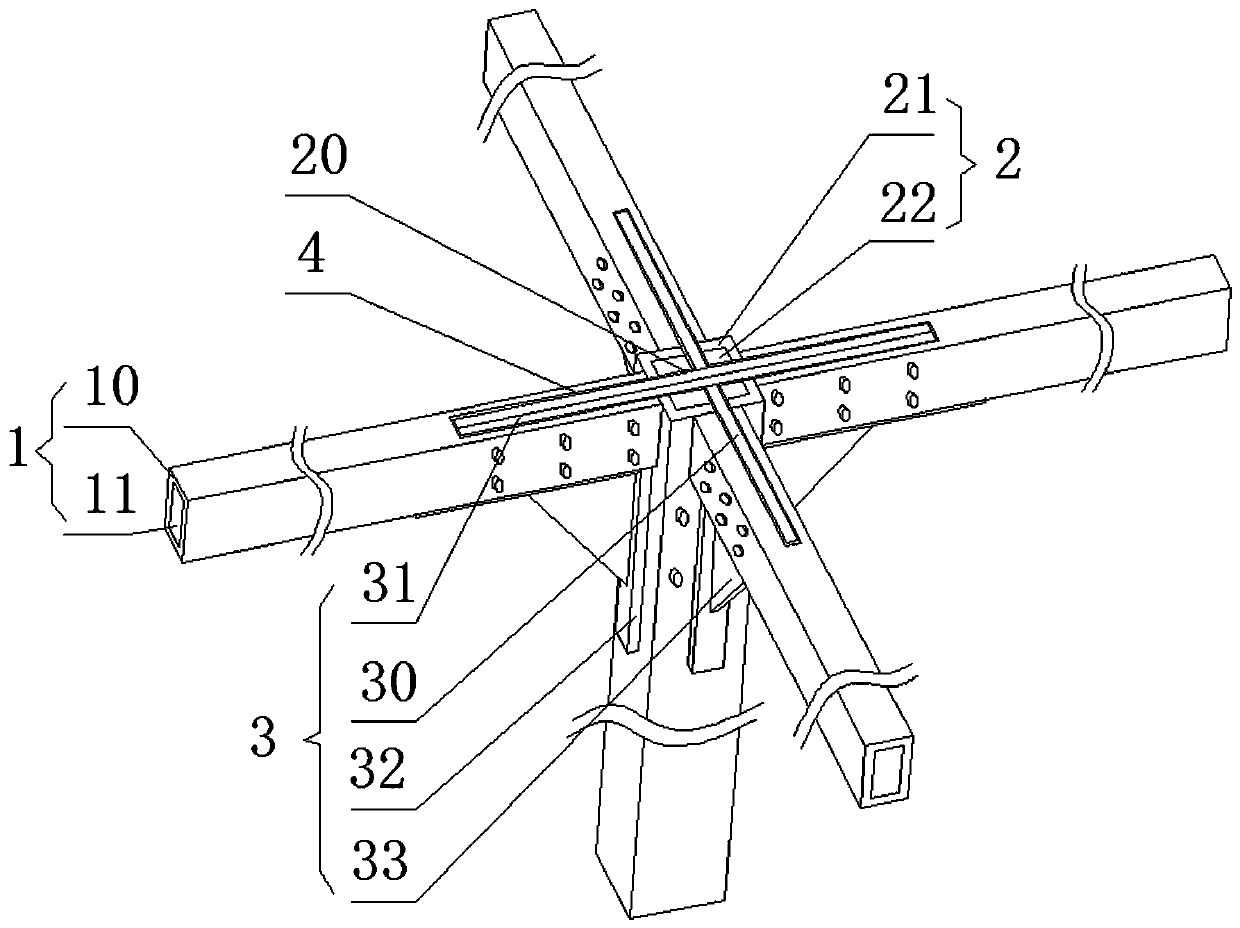

[0028] Such as Figure 1 to Figure 9 As shown, a composite beam 1, a shell 10 and a core 11, the shell 10 is a column with a "back" shape in section, the material of the shell 10 is aluminum, and the core 11 is worn on the shell For the rectangular cylinder in 10, the material of the core 11 is different from that of the shell 10, the Young's modulus of the core 11 is greater than that of the shell 10, and the core 11 is made of steel.

[0029] A composite beam and column joint connection device, comprising a composite beam 1, a support column 2 and a connecting bracket 3, the support column 2 is a vertical rectangular column, and the upper parts of the four sides of the support column 2 are respectively provided with Horizontal composite beam 1, the upper end of the support column 2 is provided with a "ten"-shaped opening 20, the end surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com