Plant fiber bed core and preparation method thereof

A plant fiber and bed core technology, applied in the field of mattresses, can solve problems such as poor plant fiber bed core performance, and achieve the effects of preventing tearing, strengthening adhesion, and good resistance to deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

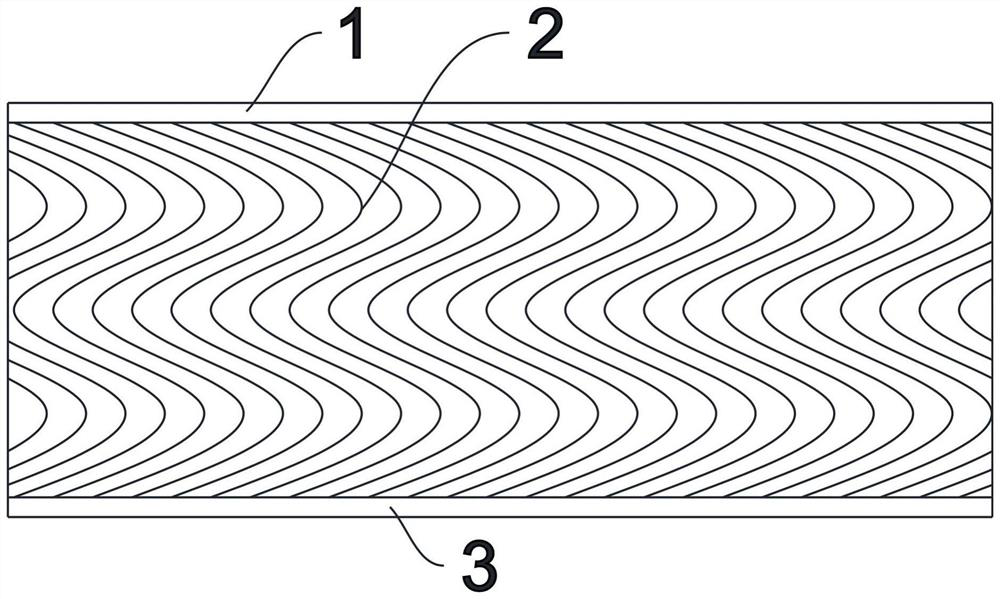

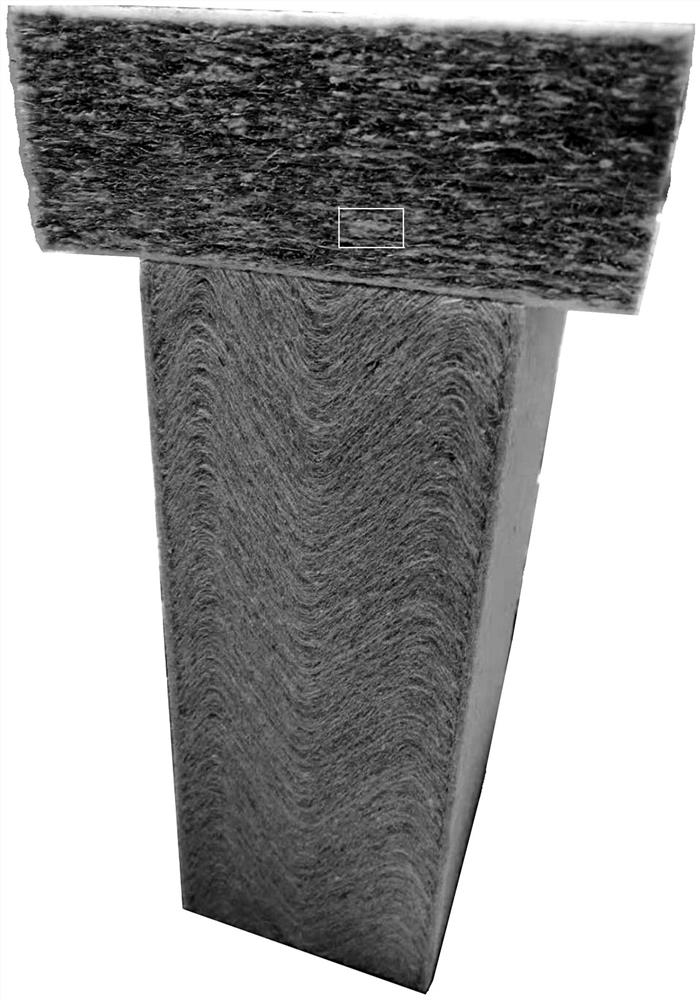

[0045] A plant fiber bed core, comprising a first protective layer, several layers of intermediate layers and a second protective layer arranged in sequence; the cross-section of the intermediate layer is M-shaped, and the first protective layer and the second protective layer Bonding with the two ends of several layers of described middle layer respectively; Calculated by weight, described middle layer comprises the bamboo fiber of 35 parts, the camel fiber of 30 parts and the polyester fiber of 25 parts; Described first protective layer and The second protective layer includes 50 parts of bamboo fiber and 35 parts of polyester fiber.

[0046] The diameter distribution of the bamboo raw fibers is 200-300 μm, the average diameter is 250 μm, the breaking strength is 5.5 cN / dtex, the breaking elongation is 6.3%, and the elastic modulus is 25-27 GPa.

[0047] The polyester fiber has a fineness of 7.6 dtex, a breaking strength of 3.7 cN / dtex, and a breaking elongation of 42.4%.

...

Embodiment 2

[0059] A plant fiber bed core, comprising a first protective layer, several layers of intermediate layers and a second protective layer arranged in sequence; the cross-section of the intermediate layer is M-shaped, and the first protective layer and the second protective layer Bonding with the two ends of several layers of described middle layer respectively; Calculate by weight, described middle layer comprises the bamboo fiber of 40 parts, the camel fiber of 35 parts and the polyester fiber of 20 parts; Described first protective layer and The second protective layer includes 65 parts of bamboo fiber and 20 parts of polyester fiber.

[0060] The raw bamboo fiber was cooked with hydrogen peroxide at a high temperature of 125° C. and a high pressure of 2 MPa for 2 hours.

[0061] A preparation method for a plant fiber bed core, comprising the steps of:

[0062] A. Prepare the first protective layer: mix bamboo fiber and polyester fiber in proportion, pre-open for 5 minutes, f...

Embodiment 3

[0071] A plant fiber bed core, comprising a first protective layer, several layers of intermediate layers and a second protective layer arranged in sequence; the cross-section of the intermediate layer is M-shaped, and the first protective layer and the second protective layer Bonding with the two ends of several layers of described middle layer respectively; Calculated by weight, described middle layer comprises the bamboo fiber of 45 parts, the camel fiber of 25 parts and the polyester fiber of 30 parts; Described first protective layer and The second protective layer includes 80 parts of bamboo fiber and 50 parts of polyester fiber.

[0072] The raw bamboo fibers were cooked with hydrogen peroxide for 1.5 hours at a high temperature of 150° C. and a high pressure of 3 MPa.

[0073] A preparation method for a plant fiber bed core, comprising the steps of:

[0074] A. Preparation of the first protective layer: mixing bamboo fiber and polyester fiber in proportion, pre-openin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com