Cast-in-situ cantilever construction hanging basket system

A technology of I-type and bottom plate, which is applied in the direction of erecting/assembling bridges, bridges, buildings, etc., can solve the problems of long construction period, complicated process, and difficult casing positioning, and achieve strong deformation resistance and easy socketing and fixing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

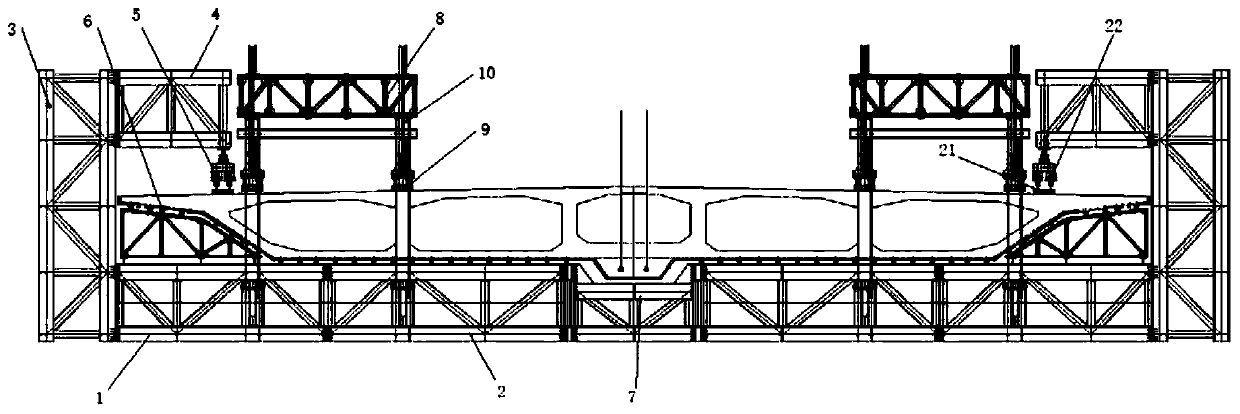

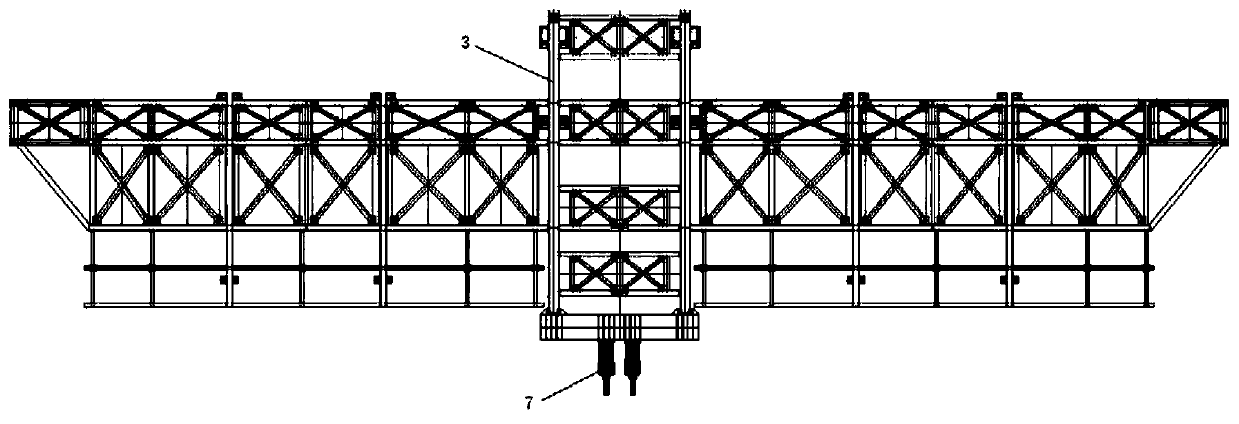

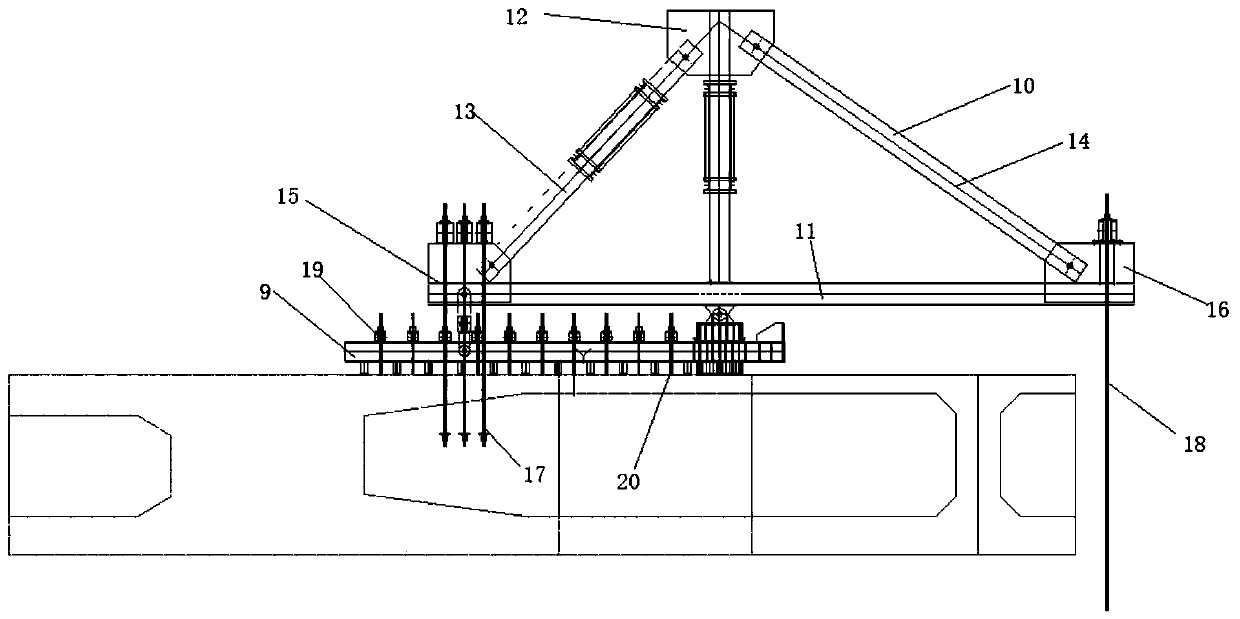

[0055] figure 1 It is the front view of the suspended construction hanging basket system of an embodiment of the present invention. figure 2 It is a side view of the suspended construction hanging basket system according to an embodiment of the present invention. image 3 It is a schematic structural diagram of an auxiliary hanger according to an embodiment of the present invention. Figure 4 It is a schematic structural diagram of an under-beam traction device according to an embodiment of the present invention.

[0056] Such as Figure 1-4 As shown, taking the construction of a certain bridge as an example, the main bridge of the bridge adopts a (100m+100m) single-tower single-cable-plane cable-stayed bridge. , 40m prefabricated partially prestressed concrete composite box girder. The starting point of the bridge is K0+262.833, across Binhe Avenue, Luohe North Embankment, Luo River, Luohe River, and the end point is K1+113.333. The span layout of the whole bridge is (4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com