Device and method for large-area nano imprinting photoetching

It is a nano-imprinting and large-area technology, which is applied in the direction of photolithography, optics, and optomechanical equipment on the patterned surface. It can solve the problems of short working life, low elastic modulus, and substrate fracture, and simplify mold manufacturing. And embossing process, long working life, easy demoulding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

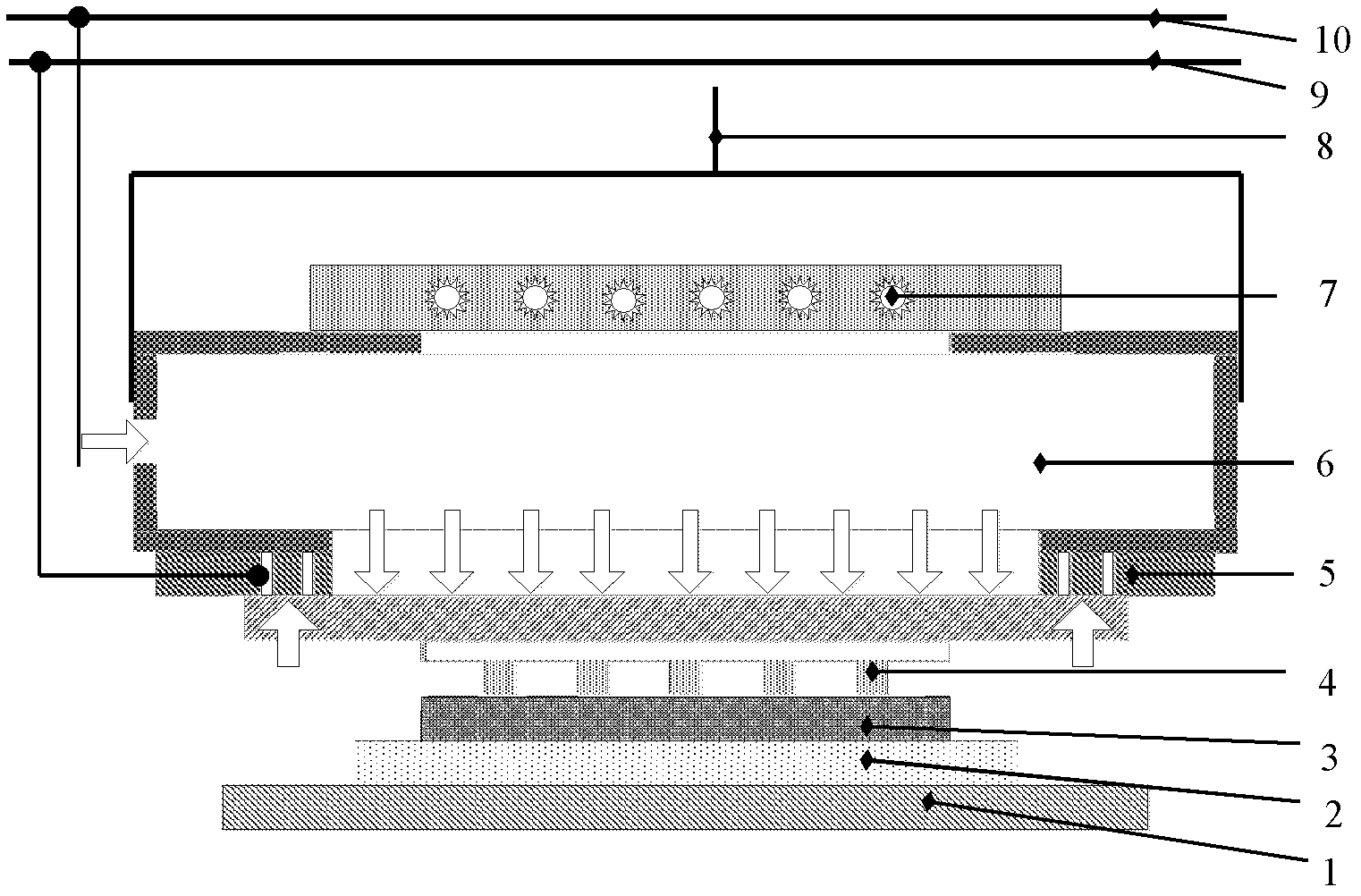

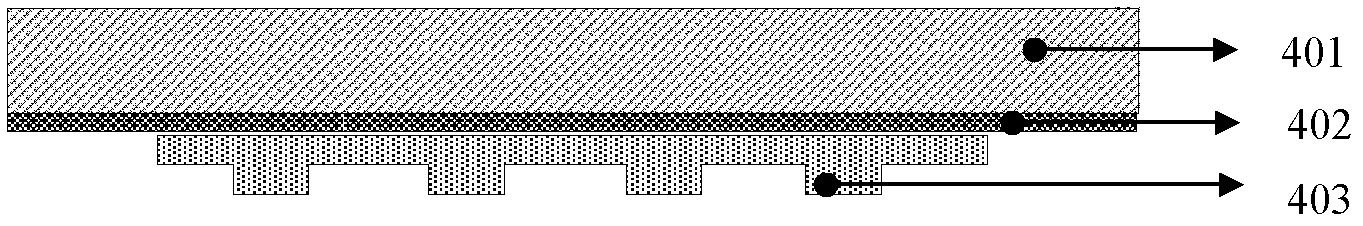

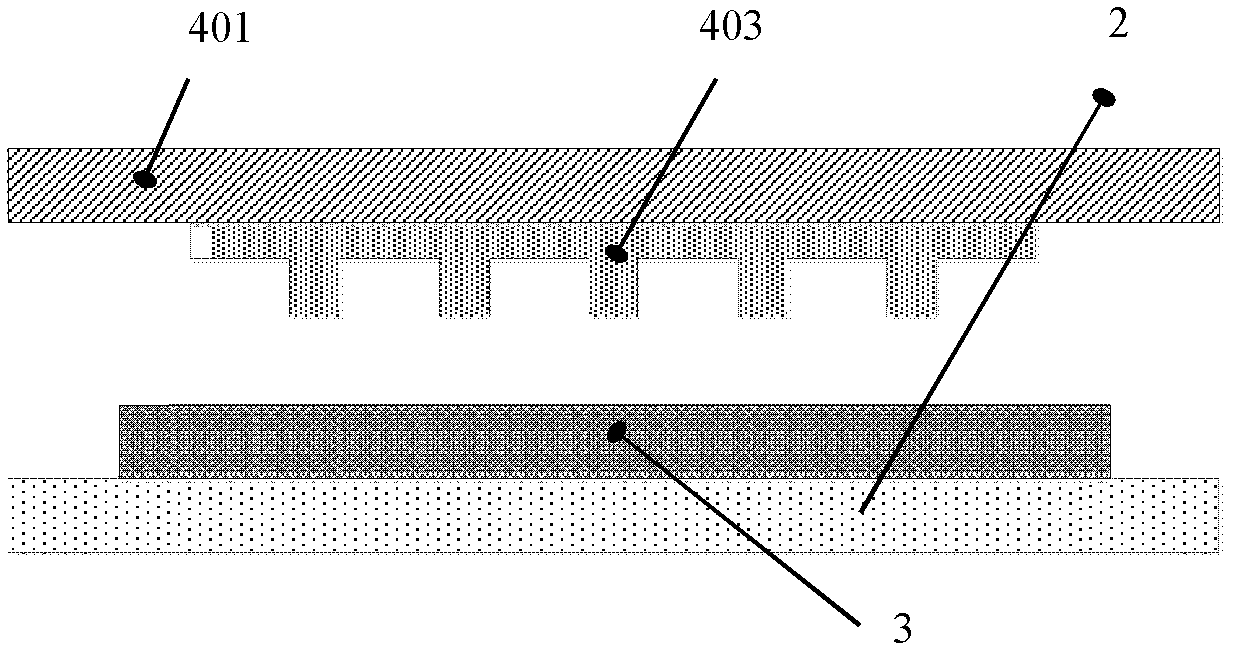

[0051] figure 1 Among them, it includes: workbench 1, substrate (wafer, epitaxial wafer) 2, liquid organic polymer 3, template 4, gas valve plate 5, gas chamber 6, ultraviolet light source 7, imprinting mechanism 8, vacuum tube Road 9, pressure pipeline 10; wherein, the whole wafer substrate 2 coated with liquid organic polymer 3 is fixed on the workbench 1; the template 4 is adsorbed on the bottom surface of the valve plate 5 through the vacuum pipeline 9 (template 4 The outermost side is adhered to the valve plate 5 to ensure that when there is no vacuum suction adsorption, the mold is still sealed with the valve plate 5), the valve plate 5 is fixed on the bottom surface of the air chamber 6, and the ultraviolet light source LED lamp array 7 is fixed On the top surface of the air chamber 6 ; the embossing mechanism 8 is connected to the air...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com