Light roadbed structure of high-speed railway

A technology for high-speed railways and roadbeds, which can be used in infrastructure engineering, roads, bridge parts, etc., and can solve the problems of wide cross-sectional area, large reinforcement range of high-speed railway bases, mutual influence, etc., and achieves great engineering application prospects. , broad application space and promotion of application value, the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

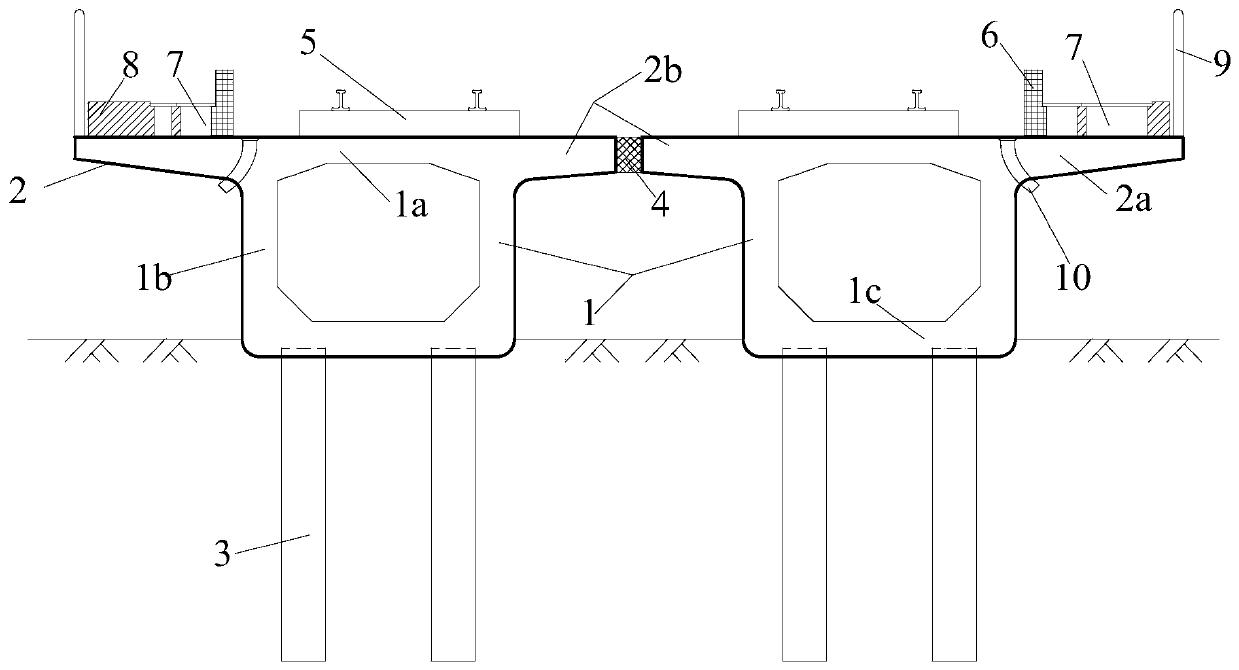

[0024] see figure 1 One embodiment of the present invention is shown, and the high-speed railway shown in the figure is a double-track high-speed railway. As shown in the figure, the light subgrade structures of the high-speed railway are arranged side by side along the extension direction of the high-speed railway, and each bears the load of the track and the train.

[0025] Each high-speed railway light subgrade structure includes a box-type subgrade 1 , a cantilever structure 2 and a rigid pile foundation 3 . Specifically, the box-shaped subgrade 1 includes: a horizontal top plate 1a, two vertical side wall plates 1b, and a horizontal bottom plate 1c formed integrally, each component is fixedly connected in turn to form a closed box-shaped structure, The outer contour of the section of the subgrade structure is a closed rectangle. The cantilever structure 2 is formed by extending outwards from the left and right ends of the top plate 1a of the box-shaped subgrade 1, where...

Embodiment 2

[0036] For the single-track high-speed railway, the high-speed railway light roadbed structure of the present invention includes a box-shaped roadbed 1, a cantilever structure 2 and a rigid pile foundation 3. The box-shaped subgrade 1 is fixedly connected by a horizontal top plate 1a, two vertical side wall plates 1b and a horizontal bottom plate 1c. The outer contour of its section is a closed rectangle; The cantilever structure 2 is formed by extension; the rigid pile foundation 3 is arranged at the bottom of the box-shaped subgrade 1, and is embedded and connected with the bottom plate 1c to play a supporting role. The cantilever structures 2 on both sides of the top plate 1a are symmetrically arranged, and the track plate and the track support system 5 are arranged in the middle of the top plate 1a. On the cantilever structure 2, anti-collision walls 6, cable troughs 7 and catenary column bases 8 are arranged in sequence from the inside to the outside. A protective fence 9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com