Ballastless track coarse-grain salty soil embankment structure considering acute air temperature influence and construction method

A ballastless track and saline soil technology, applied to roads, tracks, buildings, etc., can solve problems such as severe temperature effects, erosion, and dissolution, so as to eliminate the occurrence of dissolution, prevent water infiltration, and eliminate possible sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

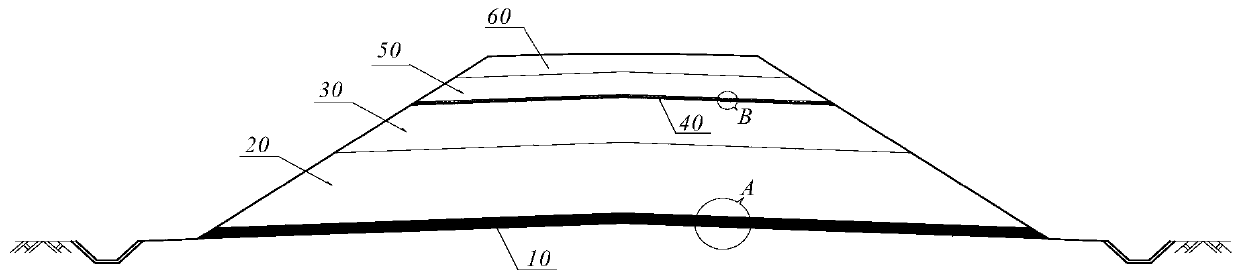

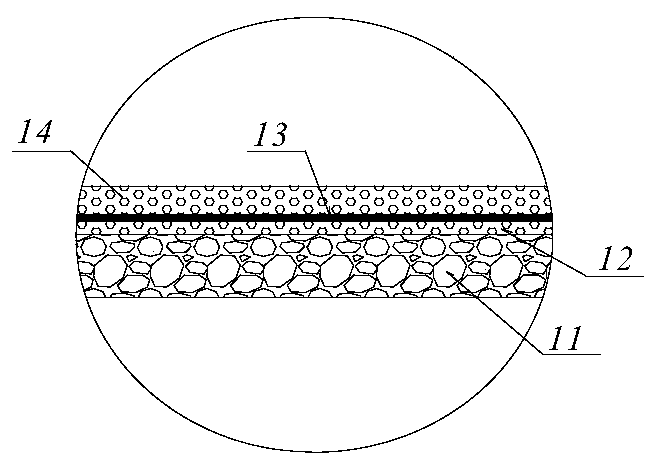

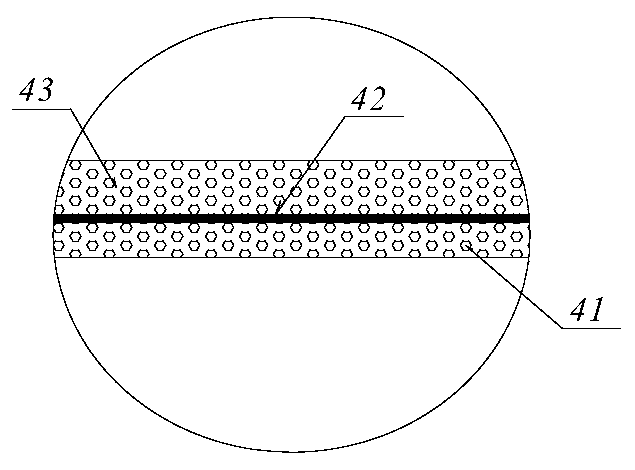

[0048] refer to Figure 1 to Figure 4 , to build a high-speed railway ballastless track embankment in a saline soil area, most of the borrow areas in this area are saline soil, it is proposed to use the structure and method proposed in this method to build a high-speed railway ballastless track embankment, the specific steps are as follows:

[0049] ①Choose the coarse-grained saline soil borrow site, collect 4 groups of soil samples (S-1~S-4) and pass indoor geotechnical sieving and chemical titration tests to determine the particle gradation curve of coarse-grained saline soil, see Figure 4 ; Determine the soluble salt content of coarse-grained saline soil m 1 , see Table 1;

[0050] ②According to the particle gradation curve of the coarse-grained saline soil in step ①, determine the coarse-fine particle size ratio R of the coarse-grained saline soil by the following formula 5

[0051]

[0052] In the formula, R 5 is the coarse-fine particle size ratio of coarse-grain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com