High speed railway embankment structure in salty soil regions

A high-speed railway and saline soil technology, which is applied in infrastructure engineering, roads, roads, etc., can solve problems such as easy impact on the environment, large project investment, and difficult material sources, so as to reduce environmental pollution, reduce project investment, and make materials cheap Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

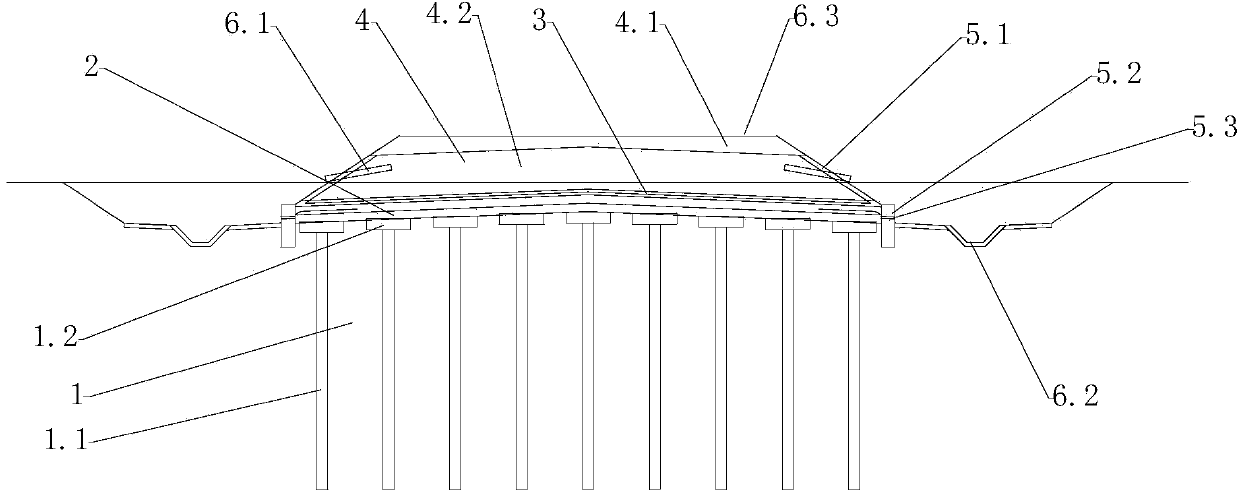

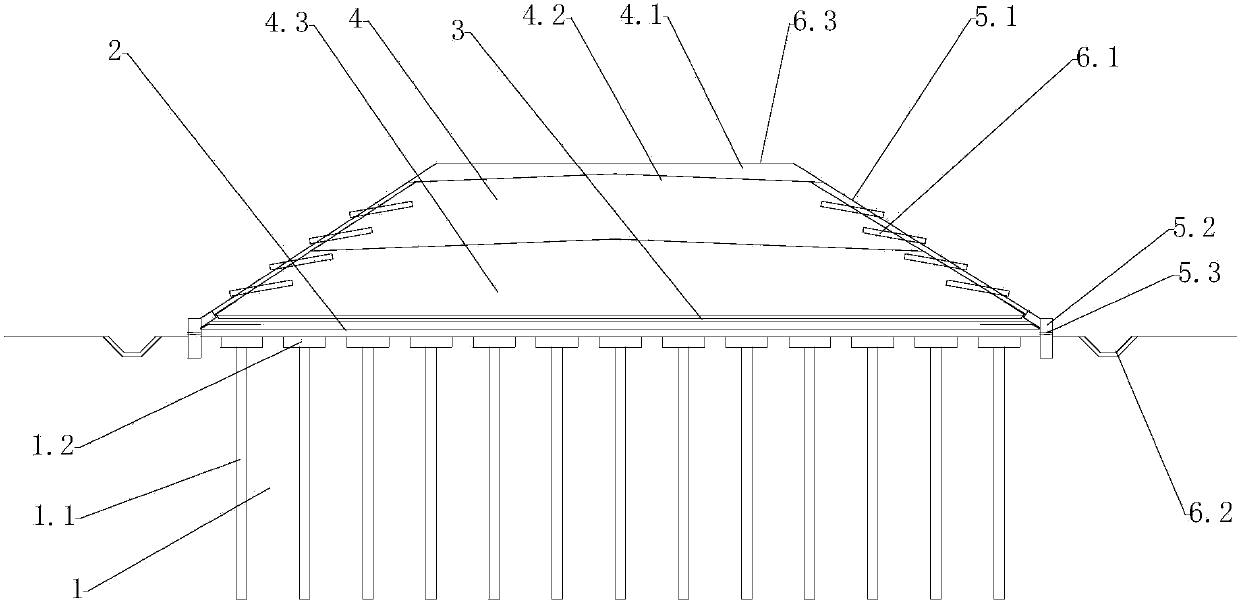

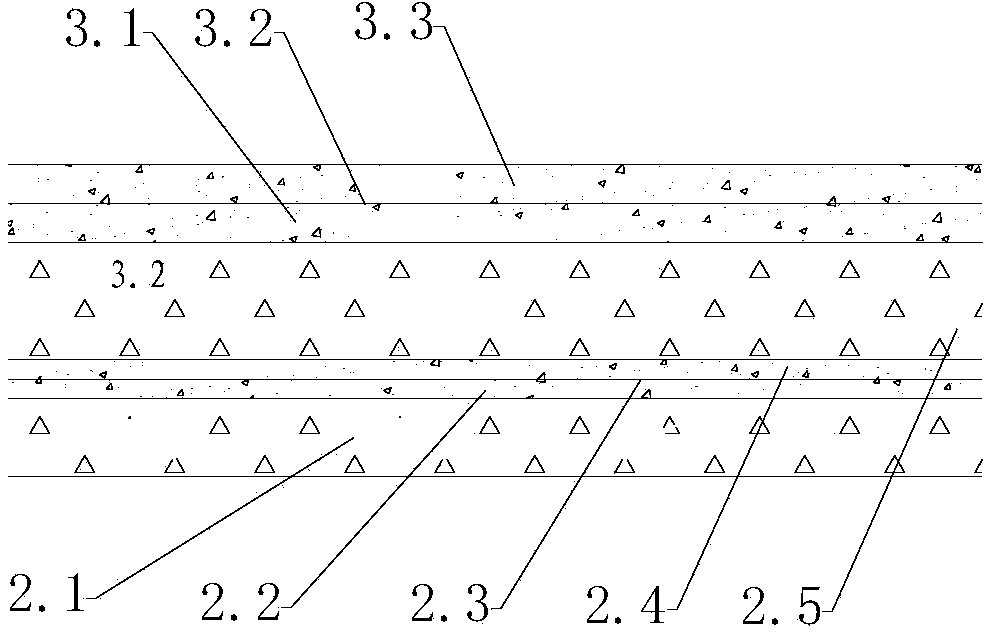

[0022] Referring to the figure, a high-speed railway embankment structure in a saline soil area, it includes a foundation reinforcement body 1 arranged in a weak foundation, a reinforced mattress layer 2 is laid on the foundation reinforcement body 1, and a reinforced mattress layer 2 is laid on top of the reinforced mattress layer 2. A saline soil partition layer 3 is laid, and a filled embankment 4 is laid above the saline soil partition layer 3 .

[0023] In this example:

[0024] The foundation reinforcement body 1 includes a plurality of reinforcement piles 1.1 arranged in weak foundations. The reinforcement piles 1.1 are cement-soil mixing piles, rotary grouting piles, CFG piles, pipe piles, plain concrete piles, or bored cast-in-place piles. The reinforcement piles 1.1 are Parameters such as pile length, pile diameter, and pil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ultimate tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com