Anchor rod supporting structure for reinforcing railway embankment slope and construction method thereof

A bolt support and embankment technology, applied in infrastructure engineering, excavation, construction, etc., can solve problems such as hidden safety hazards, high reinforcement and maintenance costs, long extension of embankment slopes, etc., to achieve reduced ground resistance, low noise, The effect of reducing construction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

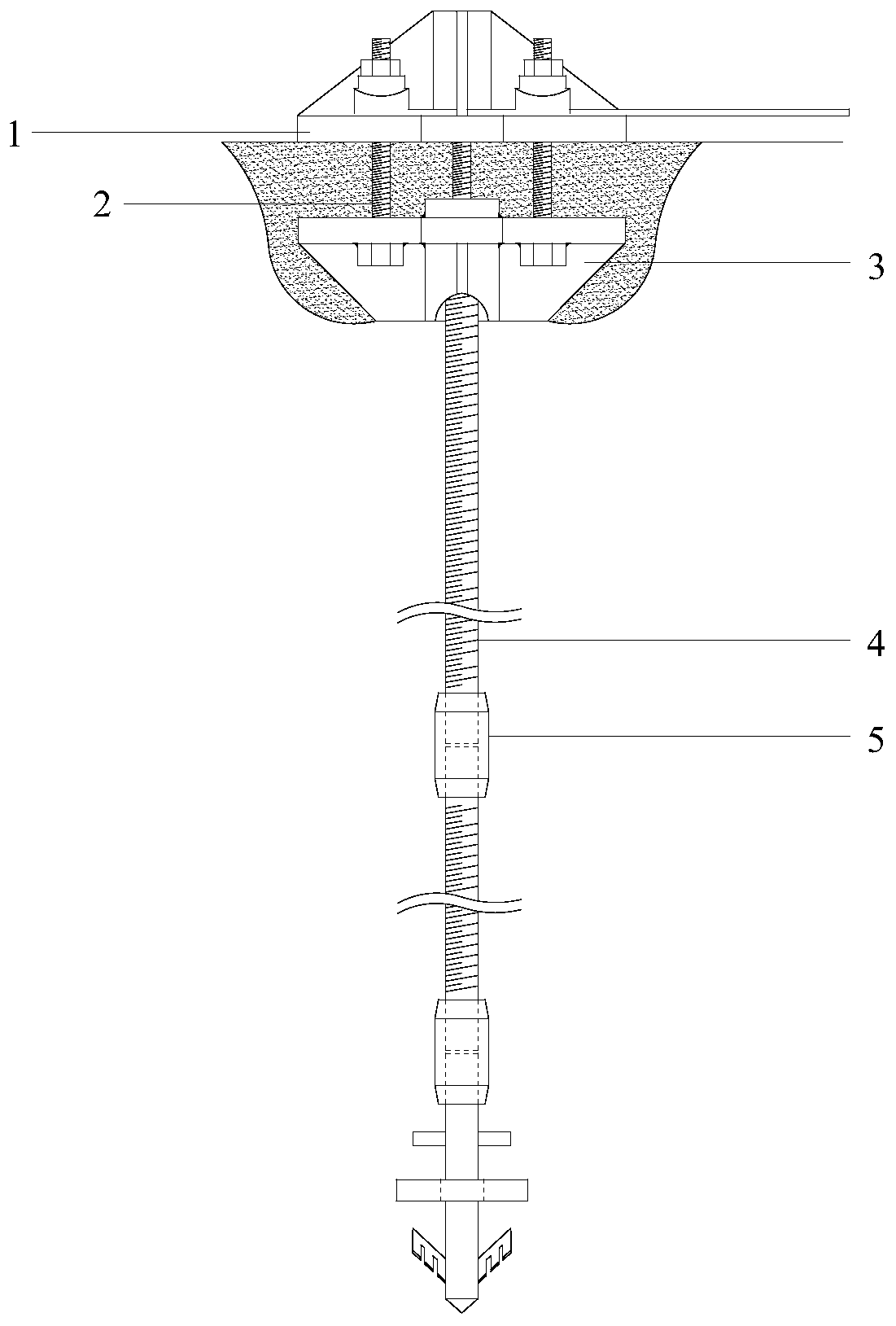

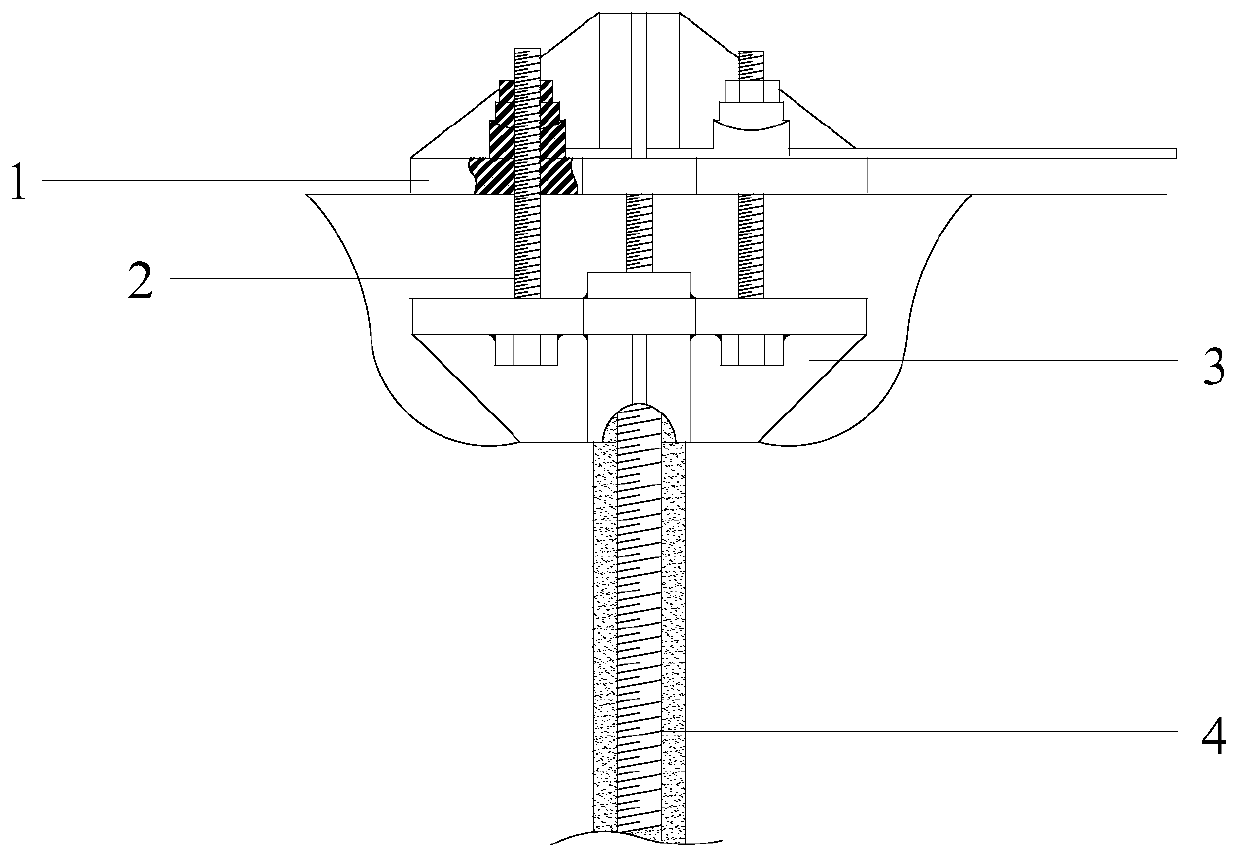

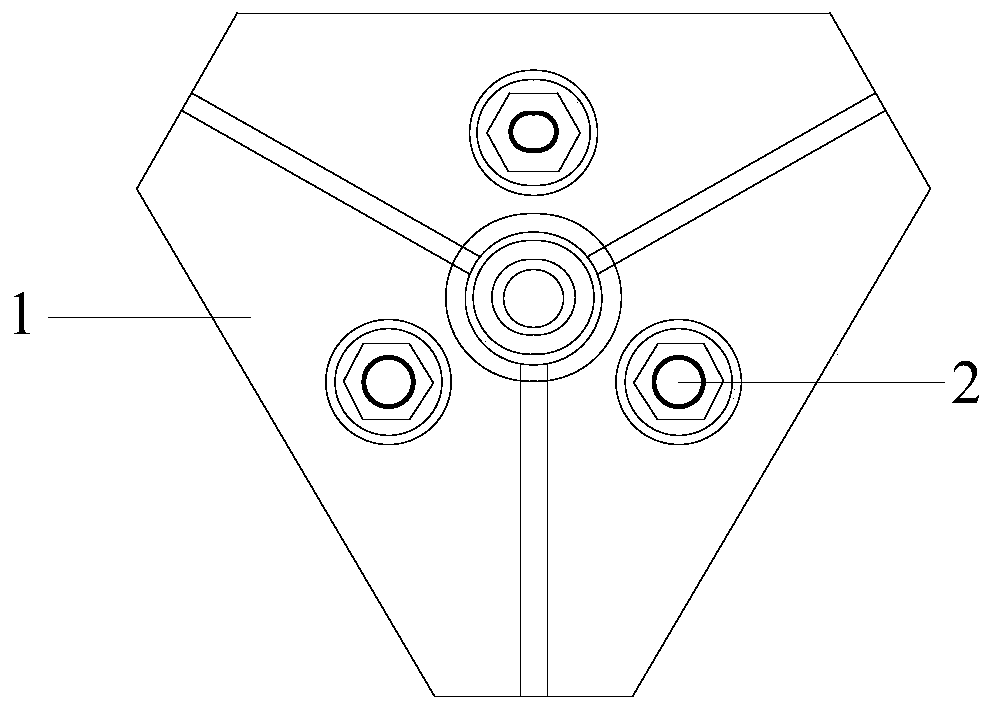

[0029] Specific implementation mode one: as Figure 1 to Figure 7 As shown, the present invention discloses a bolt support structure for railway embankment slope reinforcement, including a bolt body and an external pressure-bearing mechanism; the external pressure-bearing mechanism includes a pressure-bearing plate 1, a mounting member 3 and multiple One (three) support bolts 2; the pressure bearing plate 1 is arranged on the upper end of the installation member 3 and is arranged on the ground surface during use, and is detachably fixedly connected with the installation member 3 by a plurality of (three) support bolts 2, The bolt body includes a top-end digging mechanism, multi-section tensile steel bars 4 and a plurality of connectors 5; Tensile steel bars 4 and multiple connectors 5 are vertically stacked alternately and detachably fixedly connected, the upper end of the uppermost tensile steel bar 4 is detachably fixedly connected with the installation member 3, and the low...

specific Embodiment approach 2

[0030] Embodiment 2: This embodiment is a further description of Embodiment 1. The number of the multi-section tensile reinforcement bars 4 is the same as that of the plurality of connectors 5 .

specific Embodiment approach 3

[0031] Specific implementation mode three: as Figure 5 As shown, this embodiment is a further description of Embodiment 1. The protrusion 6 is a steel member with a triangular structure, and one corner is set downward.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com