Surface wave detection method and device for railway embankment filling quality

A detection method and embankment technology, which can be applied to measurement devices, use sonic/ultrasonic/infrasonic waves to analyze solids, and use sonic/ultrasonic/infrasonic waves for material analysis, etc. Improve the detection efficiency, reduce the construction period, and have the effect of high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] 1. Project overview

[0052] The new Chongqing-Guizhou Express Railway will be a sister section of the old Yu-Guizhou Railway, initially planned as National Railway Class I, with a total length of 345 kilometers and a speed of 200 kilometers per hour. The Chongqing-Guizhou Express Railway will be connected with the Lanzhou-Chongqing Line and the Guizhou-Yangzhou-Guangzhou Line, and will become another important rapid sea passage in the west. It will be put into operation by the end of 2017.

[0053] The line is drawn from Chongqing West Railway Station (the existing Chongqing East Railway Station) on the east side of Zhongliang, Chongqing City, passes through Qijiang River in the south, enters the territory of Tongzi County, Zunyi City, Guizhou Province, and connects to Guiyang North, the new passenger station of Guiyang City, through Zunyi City and Xifeng County stand. The length of the main line is 345km. Among them, the area in Chongqing is 112km. The territory of...

Embodiment 2

[0061] Main construction technical scheme:

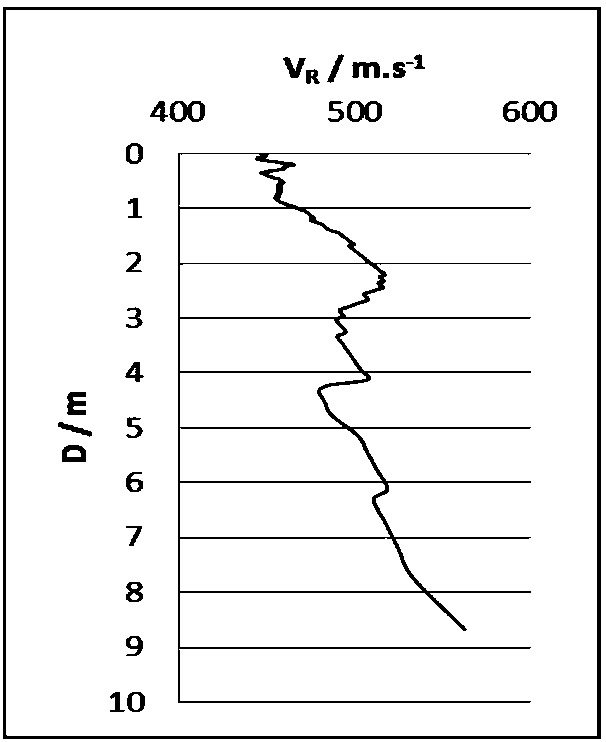

[0062] The subgrade section of DK192+911-DK192+953 has a total length of 42m, and the site is set along the line. 12-channel seismograph is used for on-site detection. The main frequency of the geophone is 4.5Hz piezoelectric ceramic geophone. The channel spacing is set to 1m, and the coverage length of each survey line is 11m. Therefore, four measuring lines need to be arranged to cover the entire subgrade section. The specific survey line layout of DK192+911-DK192+953 subgrade section, the detection direction is from small mileage to long mileage, and the measuring points are numbered from small to large starting from the position close to the excitation point. Among them, DK192 refers to the mileage number of the railway.

[0063] An 18-pound sledgehammer was selected as the vibration source for on-site data collection to excite surface waves. The excitation point was set at the small mileage end of each survey line, the offset...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com