Intelligent optimization technology for high fill filling and construction method thereof

A technology of intelligent optimization and construction method, applied in the fields of fill, construction, soil protection, etc., can solve the problems of high fill engineering stability and reliability risks, engineering disasters, etc., achieve high-efficiency real-time automatic monitoring, and save engineering Quantity and engineering cost, the effect of improving filling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

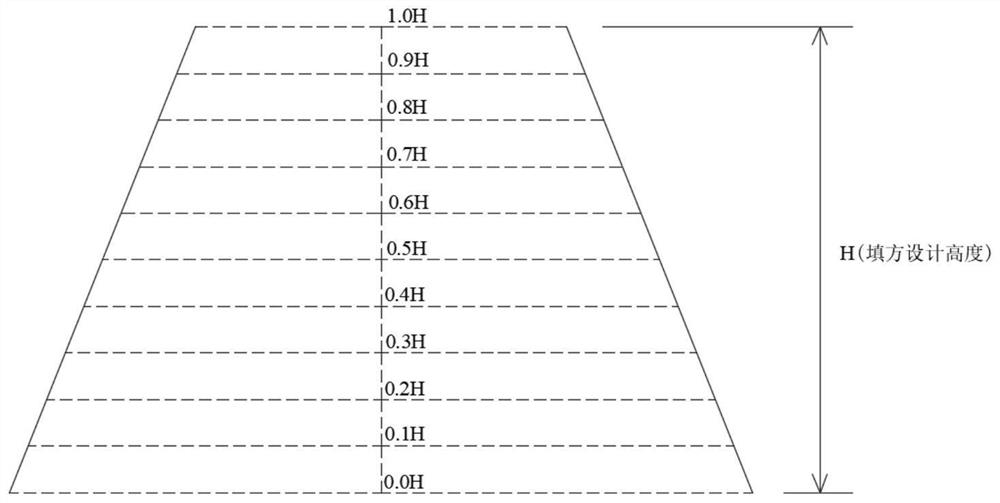

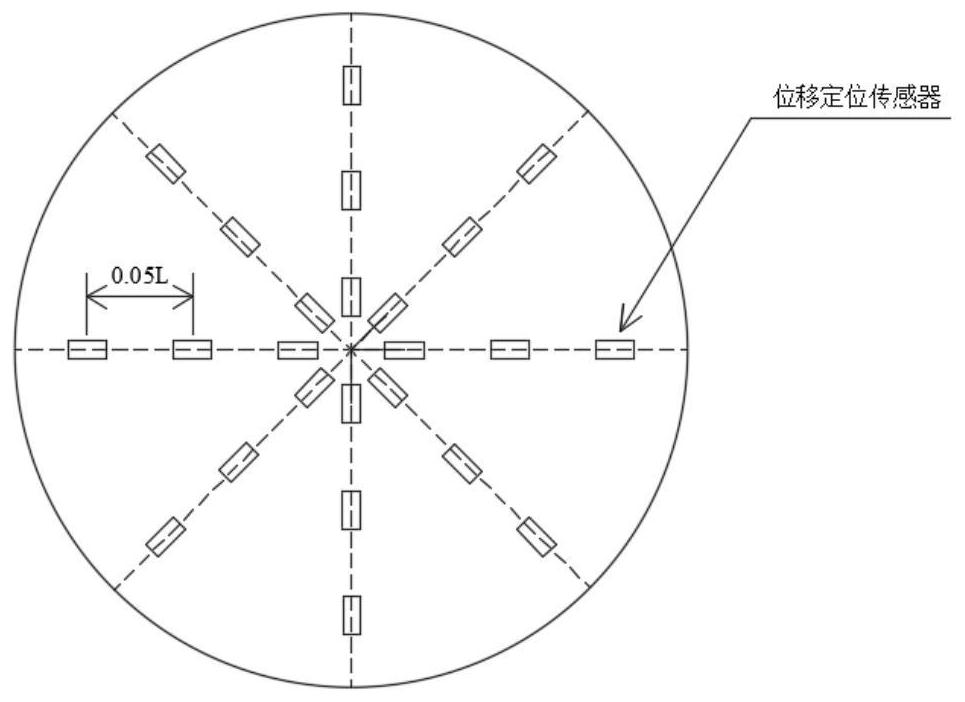

[0036] The high filling project of an airport in a mountainous area adopts the intelligent optimization technology of high filling filling for filling, and the elevation section of each filling is circular. The design height of the high fill is 50.0m, and the filling requirements of the corresponding parts are as follows: 0-0.3m below the top surface of the road foundation: filler CBR≥8%, compactness≥97%; 0.3-0.8m below the top surface of the road foundation: filler CBR ≥ 6%, compaction ≥ 96%; 0.8-4.0m below the top surface of road foundation: compaction ≥ 95%; 4.0-50m below the top of road foundation: compaction ≥ 94%.

[0037] An intelligent optimization technology for high-fill filling and a construction method thereof according to the present invention are adopted. The natural moisture content of the filler is 26%, and the filler is air-dried, and the required amount of water is added according to the difference between the moisture content of the filler after drying and t...

Embodiment 2

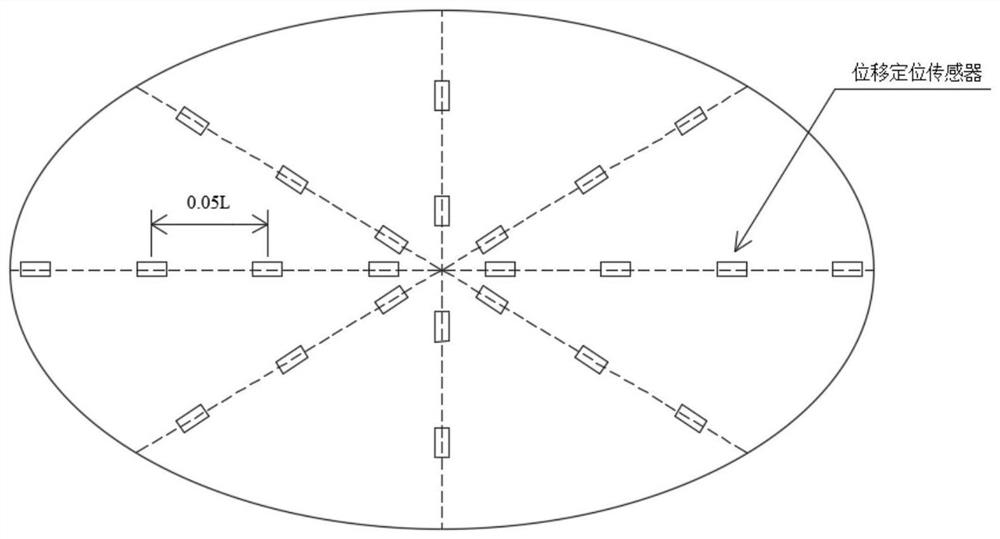

[0039] A road high filling project adopts the intelligent optimization technology of high filling filling for filling, and the elevation section of each filling is elliptical. The design height of the high fill is 80.0m, and the filling requirements of the corresponding parts are as follows, upper embankment: 0-0.7m below the bottom of the roadbed, filler CBR≥7%, compaction≥95%; lower embankment: 0.7-0.7m below the bottom of the roadbed 80.0m, filler CBR ≥ 6%, compaction ≥ 94%.

[0040] An intelligent optimization technology for high-fill filling and a construction method thereof according to the present invention are adopted. The natural moisture content of the filler is 40%. Dry the filler, and add the required amount of water according to the difference between the moisture content of the filler after drying and the optimal moisture content, so that the obtained filler is near the optimal moisture content; For layered filling, lay displacement positioning sensors in each d...

Embodiment 3

[0042] An airport high filling project adopts the intelligent optimization technology of high filling filling for filling, and the elevation section of each filling is square. The design height of the high fill is 110.0m, and the filling requirements of the corresponding parts are as follows: 0-0.3m below the top surface of the road foundation: filler CBR≥10%, compactness≥97%; 0.3-0.8m below the top surface of the road foundation: filler CBR ≥ 9%, compaction ≥ 96%; 0.8-4.0m below the top surface of road foundation: compaction ≥ 96%; 4.0-110.0m below the top of road foundation: compaction ≥ 94%.

[0043] An intelligent optimization technology for high-fill filling and a construction method thereof according to the present invention are adopted. The natural moisture content of the filler is 16%. According to the difference between the natural moisture content of the filler and the optimal moisture content, add the required amount of water so that the obtained filler is near the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com