Multifunctional semi-section channel finishing machine

A finishing machine and multi-functional technology, applied in artificial waterways, water conservancy projects, excavation, etc., can solve the problems of large manual measurement errors, labor-intensive, uneven slopes, etc., to improve quality, save labor, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

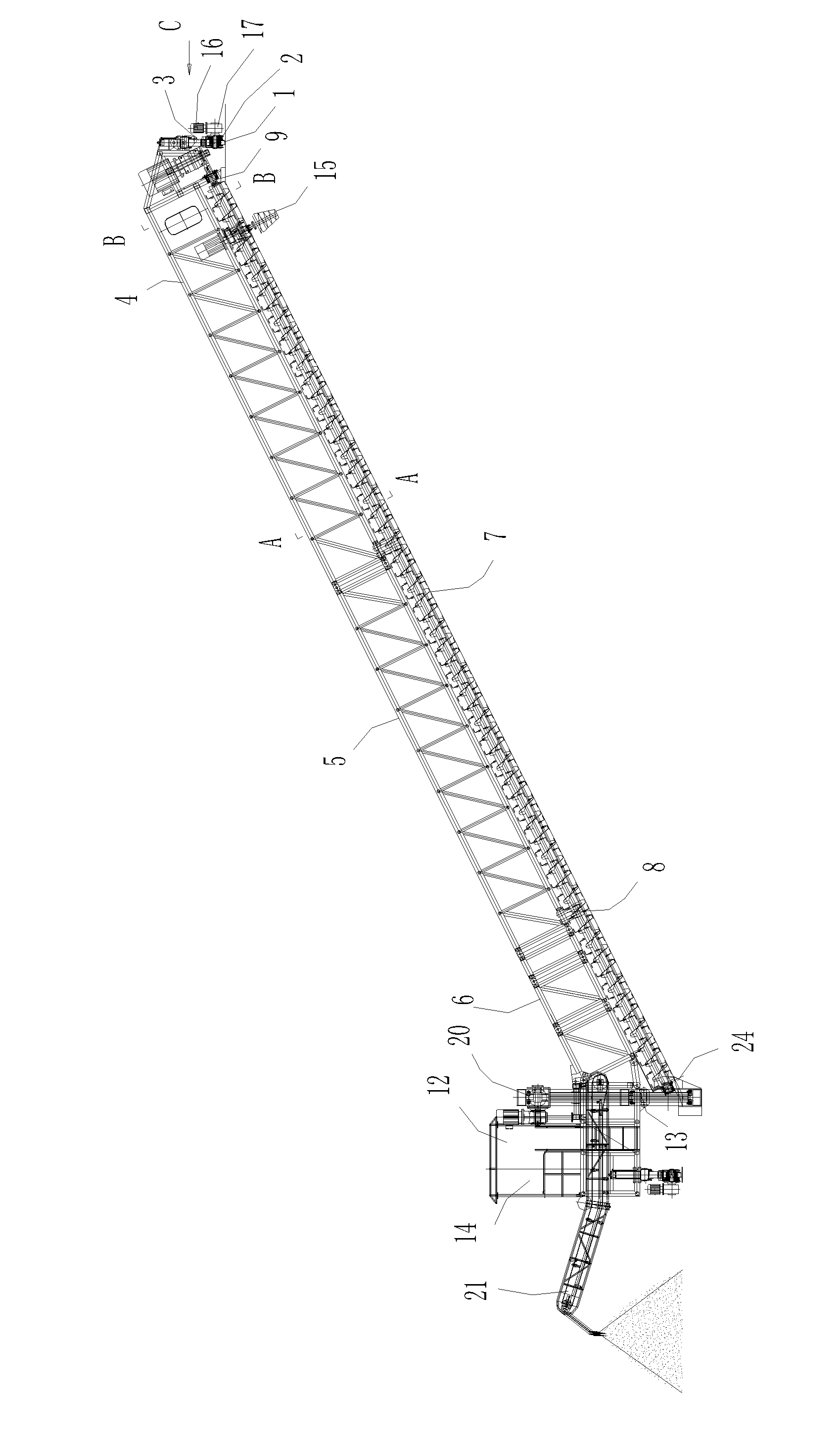

[0023] The present invention will be described in further detail below in conjunction with the accompanying drawings.

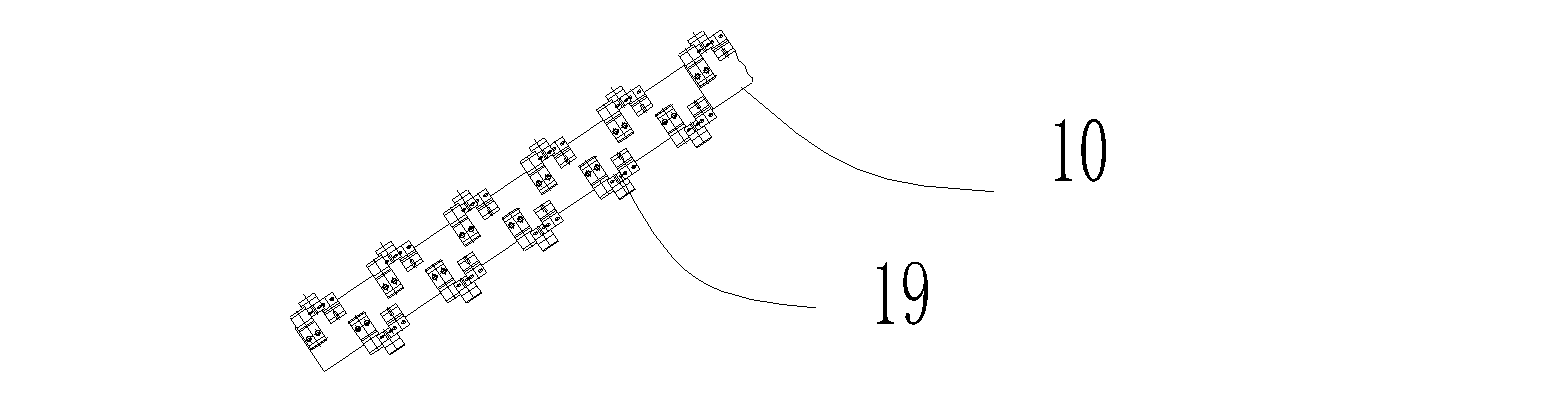

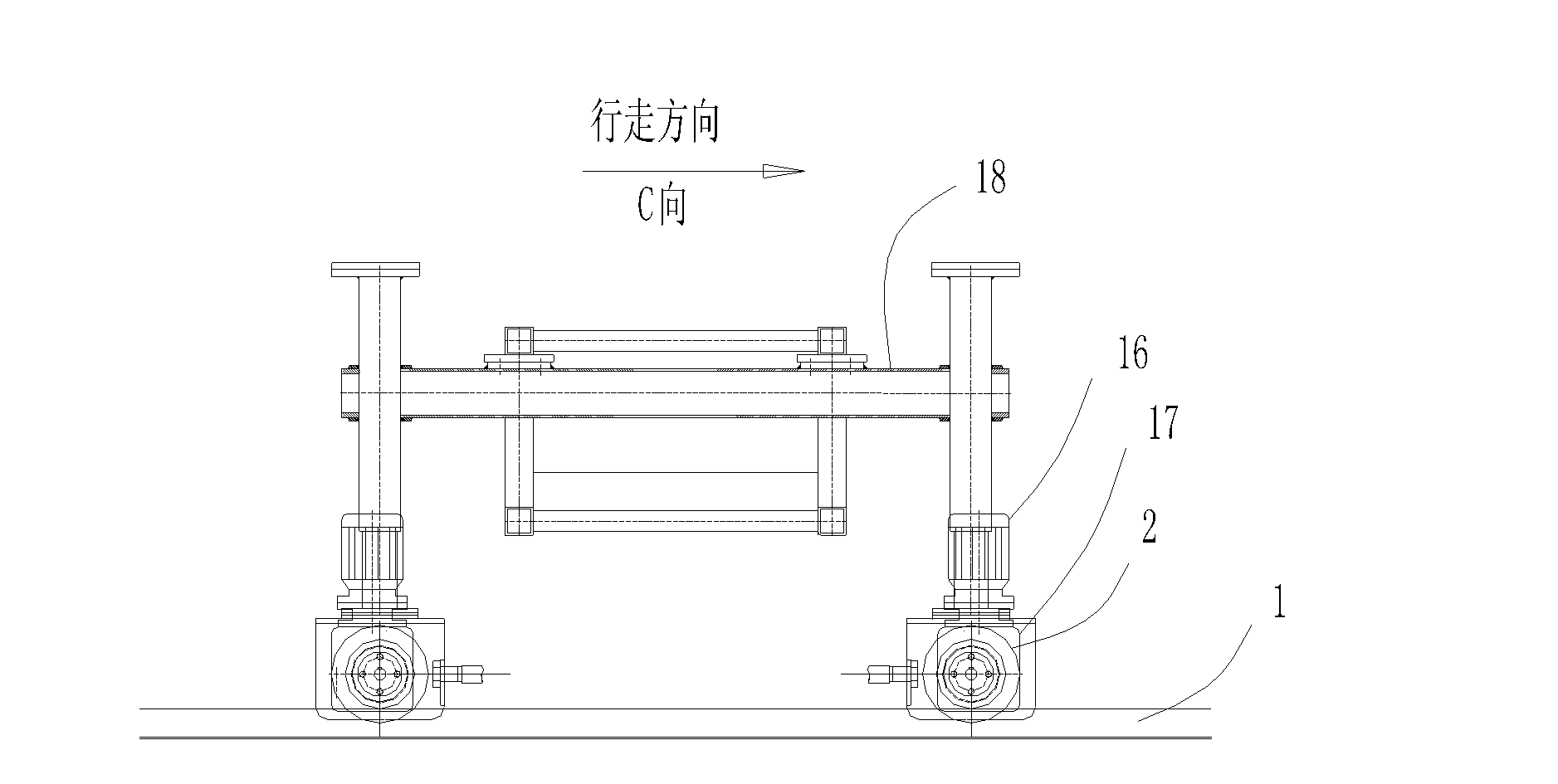

[0024] As shown in the figure, the half-section multifunctional channel finisher of the present invention has a running device, a lifting device, a leveling device, a groove repairing device, and an operating room. The running device includes two parallel guide rails 1 and wheel sets 2 running on the guide rails. The two guide rails 1 are respectively laid on the flat ground above and below the slope and extend along the ditch. The travel motor 16 is driven after being decelerated by the travel reducer 17. The wheel set makes the finishing machine walk, and the walking speed reducer 17 is installed on the wheel set 2 . Lifting device can be worm gear screw structure, also can be hydraulic pressure structure, is installed between wheel group 2 and traveling frame 18, makes traveling frame 18 can relative wheel group 2 lifts. Two groups of walking frames 18 ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com