Hard plastic soil foundation existing high-speed railway embankment side width structure a construction method

A soil and foundation technology, applied in the direction of roads, buildings, tracks, etc., can solve problems such as difficult control, high-speed railway embankment width deformation, etc., to avoid the impact, reduce the impact, and reduce its own weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

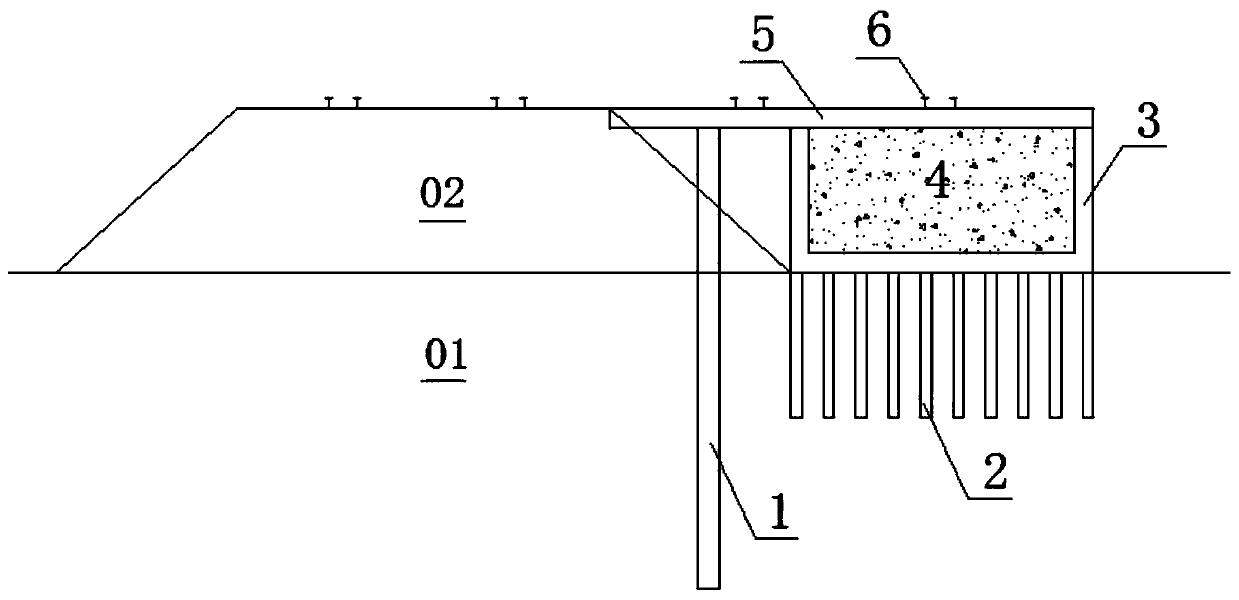

[0036] like figure 1 As shown, a kind of hard plastic soil foundation of the present invention has the wide structure of embankment side of high railway, including:

[0037] Several isolation support piles 1 are used to be arranged at intervals along the line on the slope of the existing filling body 02, and the bottom thereof goes deep into the hard plastic soil foundation 01; specifically, the diameter of the isolation support piles 1 is 1m-1.5m , the set spacing is 2m-4m;

[0038] Several CFG piles 2 are used to be arranged at intervals in the hard plastic soil foundation 01 outside the slope toe of the existing filling body 02; specifically, the depth of the isolation support pile 1 inserted into the hard plastic soil foundation 01 is greater than the The CFG pile 2 is inserted into the depth of the hard plastic soil foundation 01, and the setting depth of the CFG pile 2 is equal to or greater than the reinforcement depth of the existing high-speed rail foundation;

[00...

Embodiment 2

[0045] like figure 1 As shown, a kind of hard plastic soil foundation of the present invention has the construction method of the existing high-speed railway embankment width structure, which is used for construction as described in Example 1. The existing high-speed railway embankment width structure of the hard plastic soil foundation. The method includes the steps of:

[0046] A. On the existing filling body 02 slope, adopt a full casing drilling rig to drill and construct the isolation support pile 1, and reserve 30cm connecting steel bar at the pile top of the isolation support pile 1; the setting depth of the isolation support pile 1 meets According to the vertical deformation requirements of the side-width subgrade, the longitudinal spacing of the isolation support piles 1 along the line meets the stress transmission requirements of the side-width subgrade; specifically, the spacing is 2m-4m;

[0047] B. Construction of the CFG pile 2 in the hard plastic soil foundatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com