Super-soft dredger fill surface layer solidification crusting and foundation treatment method

A foundation treatment and dredging filling technology, which is applied in soil protection, infrastructure engineering, construction, etc., can solve the problems of large quantities, shortage of sand and gravel materials, and low degree of mechanization, and achieve simple and fast operation, shortening construction period, and mechanization high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The following are the construction steps of this technology:

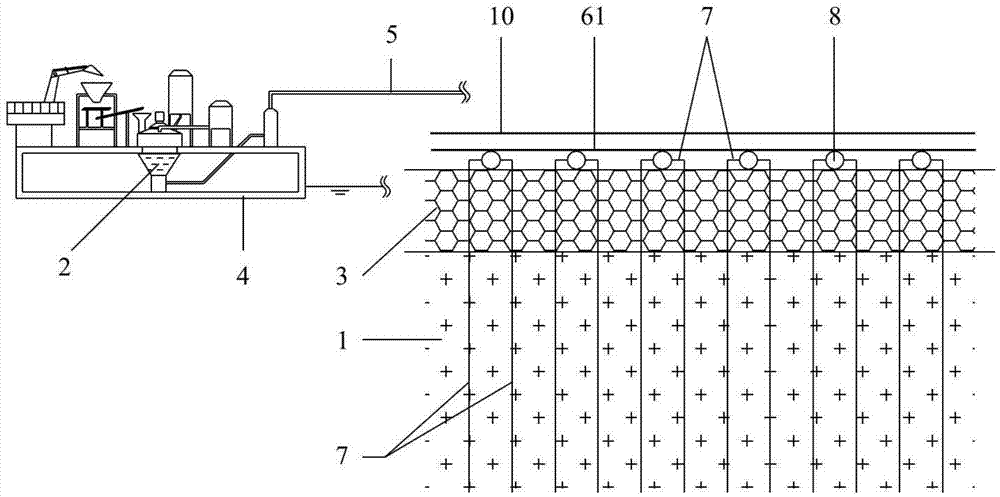

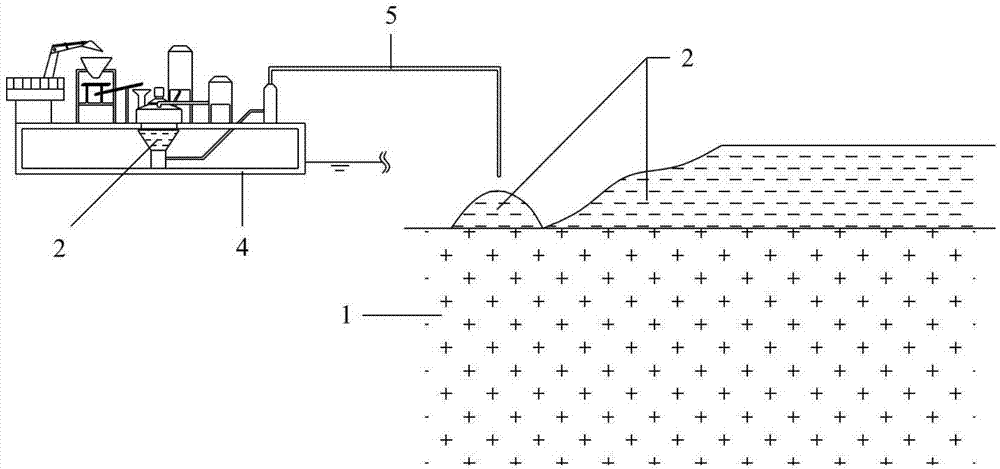

[0029] Step 1: Dredging fill super soft dredging fill foundation 1. Such as figure 2 As shown, in the reclamation area, the traditional filling method is used to fill the ultra-soft filling soil foundation 1.

[0030] Step 2: Pour the fluid plastic sea mud-water-curing agent mixture 2, and solidify the crust to form a hard shell layer 3. Such as figure 2 As shown, after the supersoft dredging land foundation 1 is blown and filled, the undisturbed sea mud, water and cement can be mixed on the large construction ship 4 to form a flow-plastic state sea mud-water-curing agent mixture, wherein the present invention adopts Step 2) The medium-flow plastic sea mud-water-curing agent mixture is formed by mixing the original sea mud, water and cement; the original sea mud is directly salvaged from the seabed by a construction ship; the flow-plastic sea mud-water-curing agent The water content in the mixture (the...

Embodiment 2

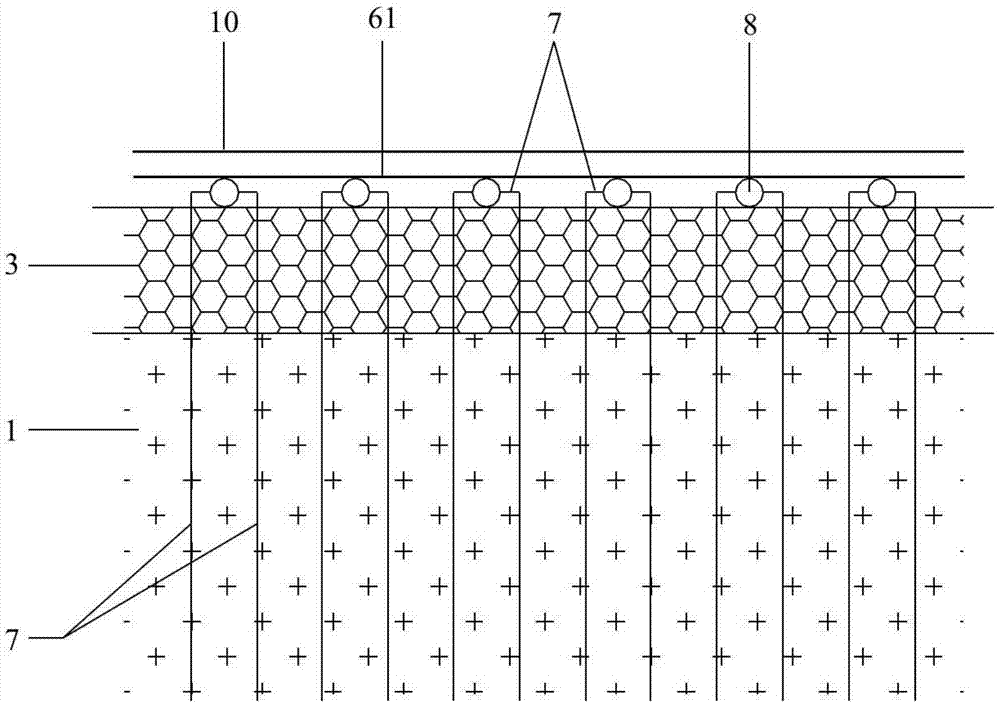

[0035] After completing steps 1 to 4 as in Example 1, carry out surcharge preloading construction.

[0036] After the horizontal drainpipe 8 is connected to the horizontal drainpipe 12, a layer of non-woven fabric is laid on the horizontal drainpipe 8, and then preloaded in layers.

Embodiment 3

[0038] After completing steps 1 to 4 as in Example 1, carry out vacuum combined surcharge preloading construction.

[0039] First carry out vacuum preloading for 10 days, and then lay a layer of non-woven fabric on the sealing film, and carry out layered surcharge preloading.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com