High-speed railway wide and large embankment settlement control method adopting cement mixing piles

A technology for cement mixing piles and high-speed railways, which is used in the protection of roads, sheet pile walls, and soil, etc. It can solve problems that are difficult to meet the requirements of long-term safe and comfortable operation of high-speed railways, unstable mechanical properties and durability, and station embankment projects. Uneconomical construction and other problems, to achieve the effect of reducing uneven lateral settlement, ensuring safety performance, and smooth transition of deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

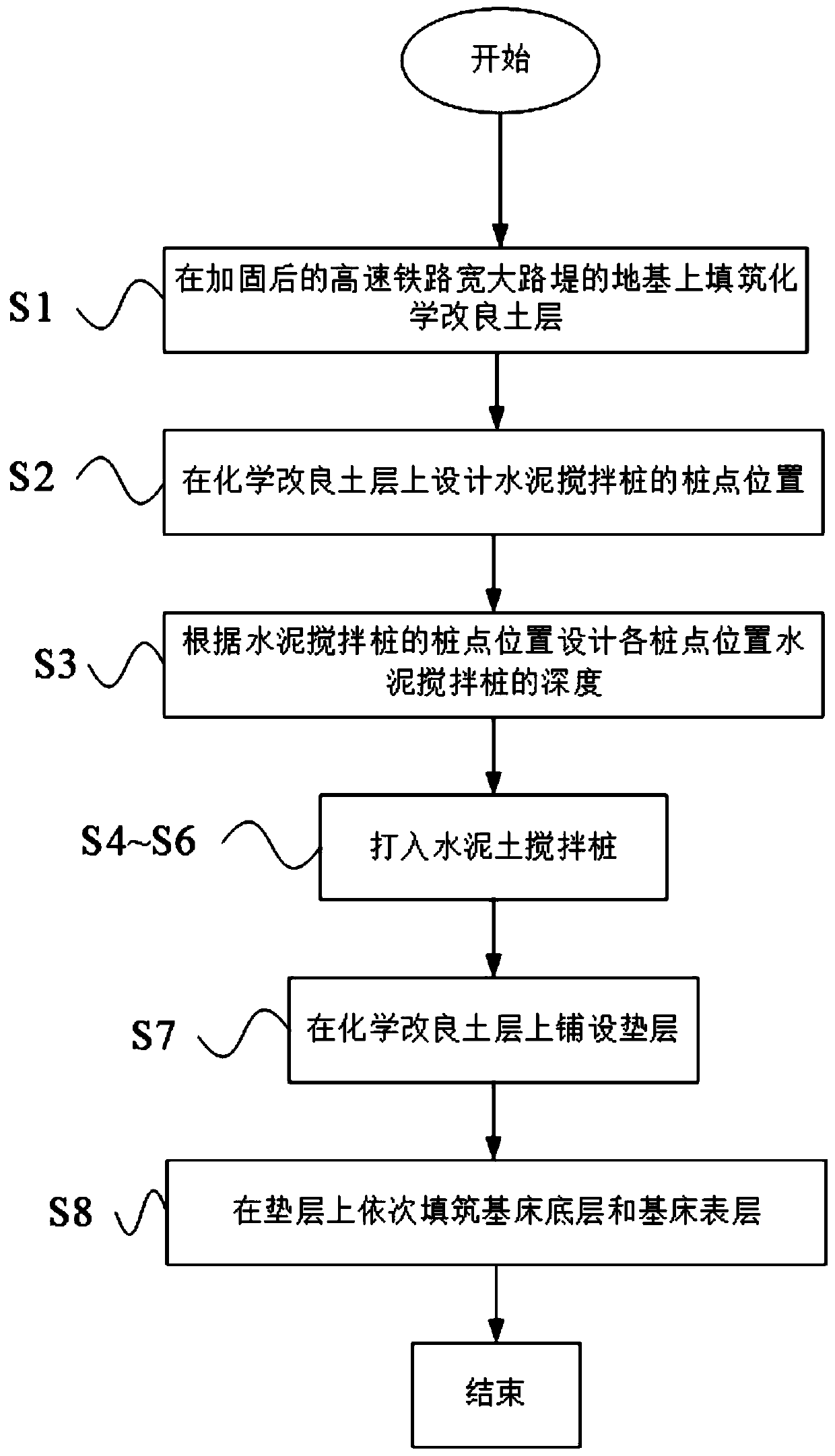

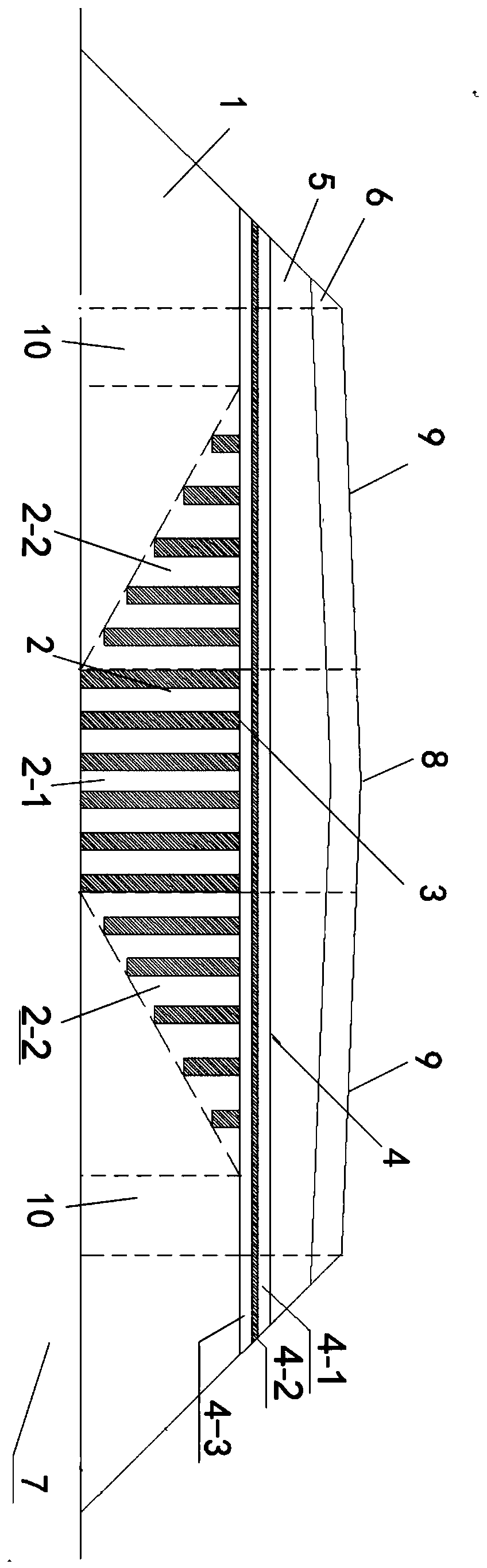

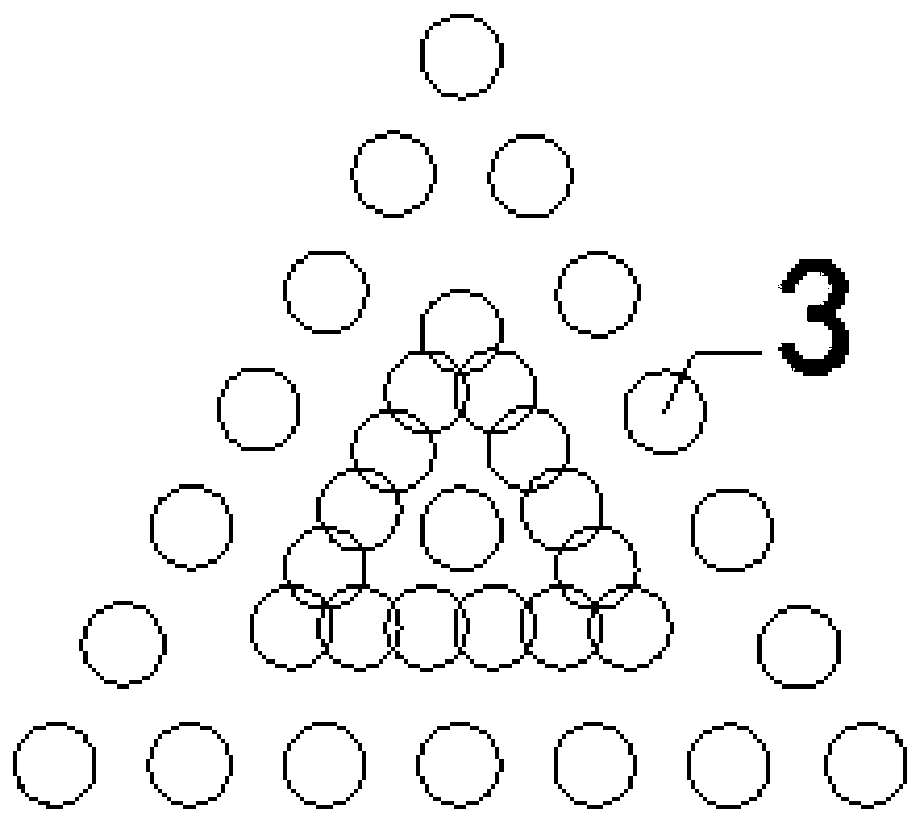

[0041] A settlement control method for wide embankments of high-speed railways using cement mixing piles. In this method, a chemically modified soil layer 1 is filled on the foundation 7 of the high-speed railway. The chemically modified soil has low cost and a wide range of applications, but its mechanical properties and durability are not good. stable, then drive cement mixing pile 3 into chemically modified soil layer 1, and reinforce chemically modified soil layer 1. Increase and decrease, so that the bearing capacity and anti-deformation capacity of the embankment are large in the middle and small on both sides, reduce the linear settlement and lateral uneven settlement, and realize the smooth transition of deformation, and then lay the cushion 4 and fill the bottom layer of the foundation bed 5 and foundation bed surface layer 6 to complete the laying of the wide embankment of the high-speed railway, effectively reduce the economic cost, and prevent the settlement of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com