High-speed railway embankment reinforcement structure in saline soil area

A high-speed railway and saline soil technology, applied in roads, roads, buildings, etc., can solve the problems of violating the design concept of saving and environmental protection, high construction cost, and less research, so as to reduce the amount of foundation treatment, construction safety, and The effect of simple and clear structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

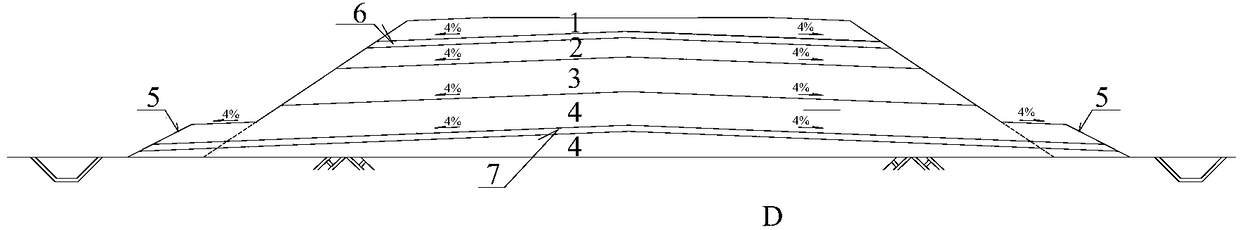

[0013] refer to figure 1 , the high-speed railway embankment reinforcement structure in saline soil area of the present invention comprises:

[0014] a. The surface layer 1 of the subgrade bed is arranged on the subgrade surface, arranged symmetrically from left to right, and filled with graded gravel without soluble salt;

[0015] b. The structural layer 2 on the bottom layer of the foundation bed is set below the surface layer 1 of the foundation bed, with a thickness of 1.0m, and is filled with coarse-grained soil with a soluble salt content of less than 0.3%;

[0016] c. The lower structural layer 3 of the subgrade bed is arranged below the upper structural layer 2 of the subgrade bottom layer, with a thickness of 1.3m, and is filled with coarse-grained soil with a soluble salt content of less than 1.5% and a fine particle content of less than 5%...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com