Ballastless track base plate post-cast strip breaking device, system and method

A ballastless track and post-casting belt technology, applied in tracks, track maintenance, roads, etc., can solve the problems of long time consumption, large driving influence, concrete shrinkage cracks, etc., and achieve good removal effect, good safety, and high degree of automation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

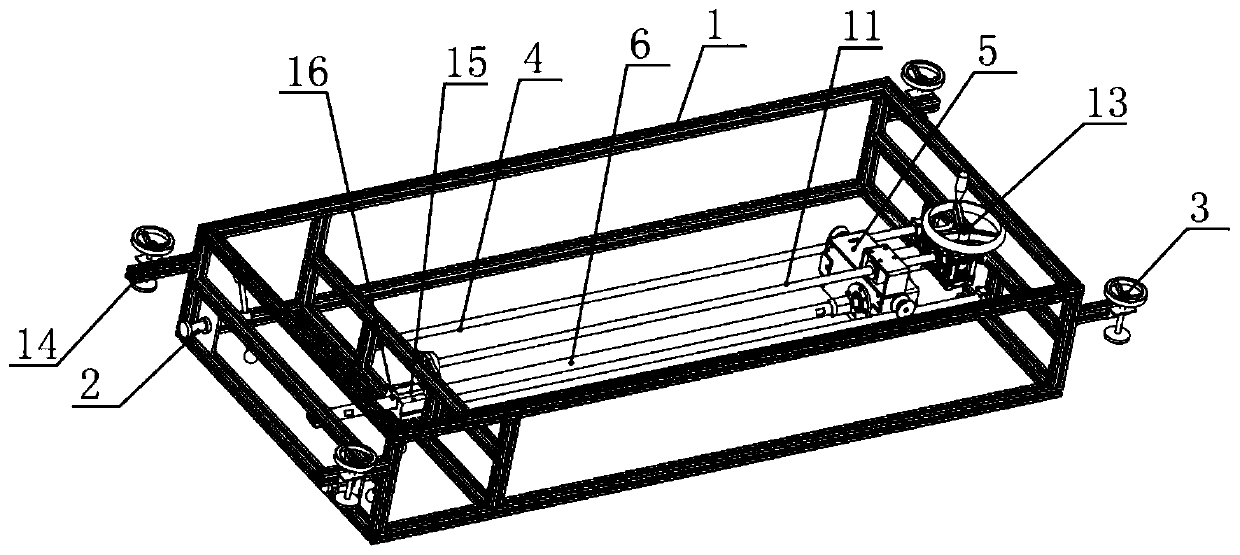

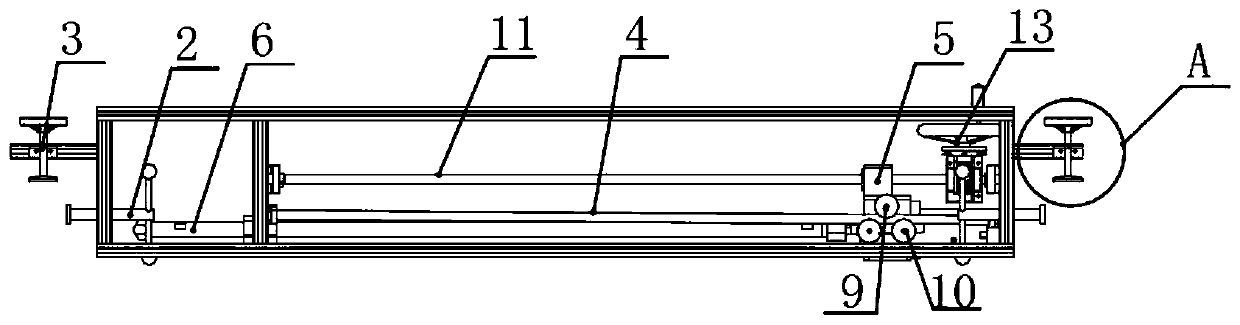

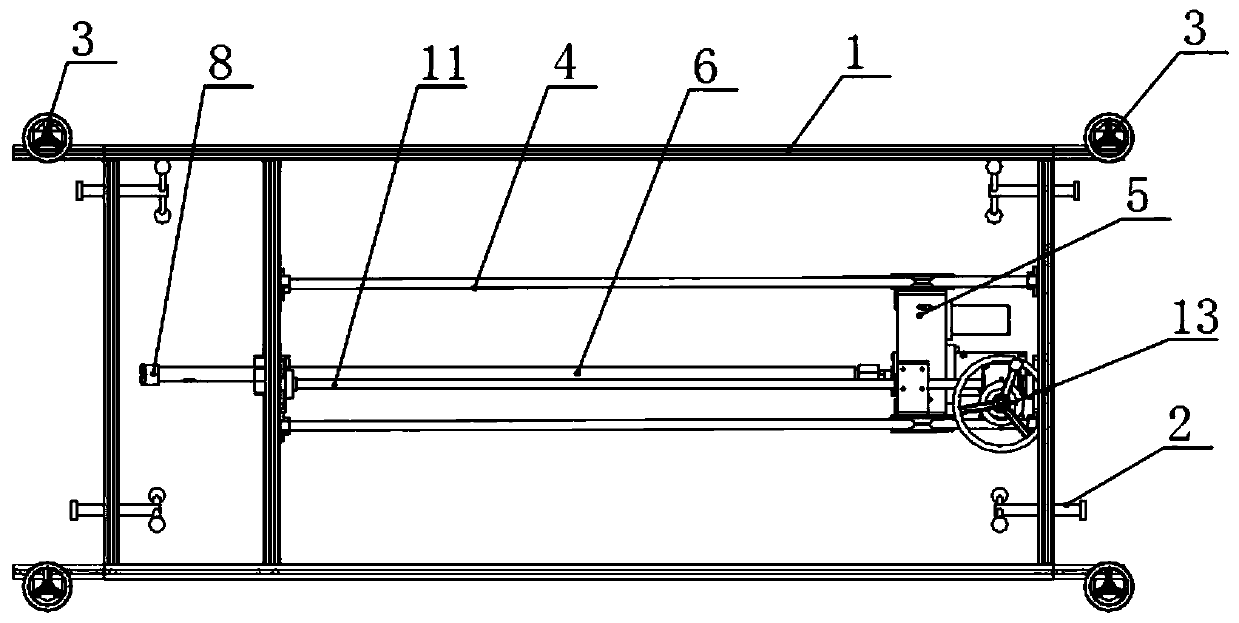

[0047] The present invention will be described in further detail below through specific implementation examples and in conjunction with the accompanying drawings.

[0048] Figure 1 to Figure 6 Shown is a ballastless track base plate post-casting strip removal device provided by the present invention, including a lateral locking mechanism 2 on which the frame 1 is fixed; the frame 1 is also fixedly installed with a guide Shaft 4, and the drive mechanism 5 that slides along the guide shaft 4 is also installed on the frame 1, and the lifting mechanism 3 that makes the drive mechanism 5 move up and down is also installed on the frame 1; The hollow shaft 6, and the input end of the hollow shaft 6 is connected with a rotary joint 7;

[0049] The frame 1 is a frame structure, and the lateral locking mechanism 2 is used to lock and fix the frame 1 when it is in use, so as to prevent the entire frame 1 from being damaged due to the reaction force of high-pressure water during the rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com