Ballastless track base plate post-cast strip bilateral breaking device, system and method

A ballastless track and base plate technology, applied in tracks, track maintenance, track superstructure and other directions, can solve the problems of low removal efficiency, inability to move left and right, low efficiency, etc., to improve removal efficiency, reduce operators, and achieve automation. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

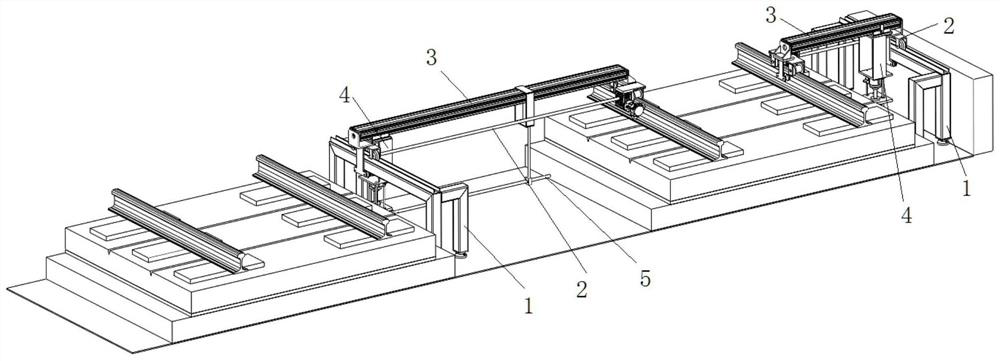

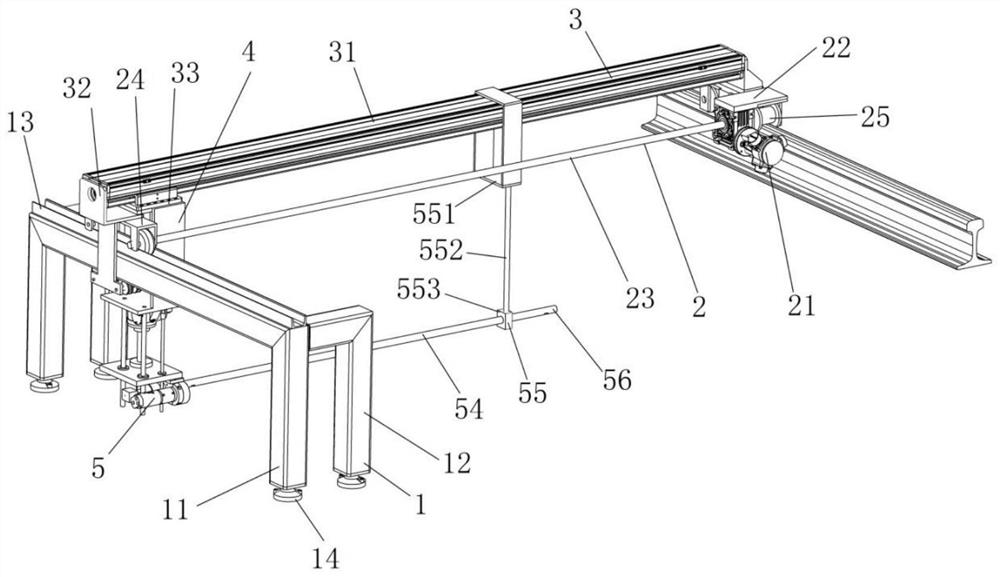

[0066] A double-sided breaking device for the post-casting belt of the ballastless track base plate, such as figure 1 and 2 shown, including:

[0067] Rack 1;

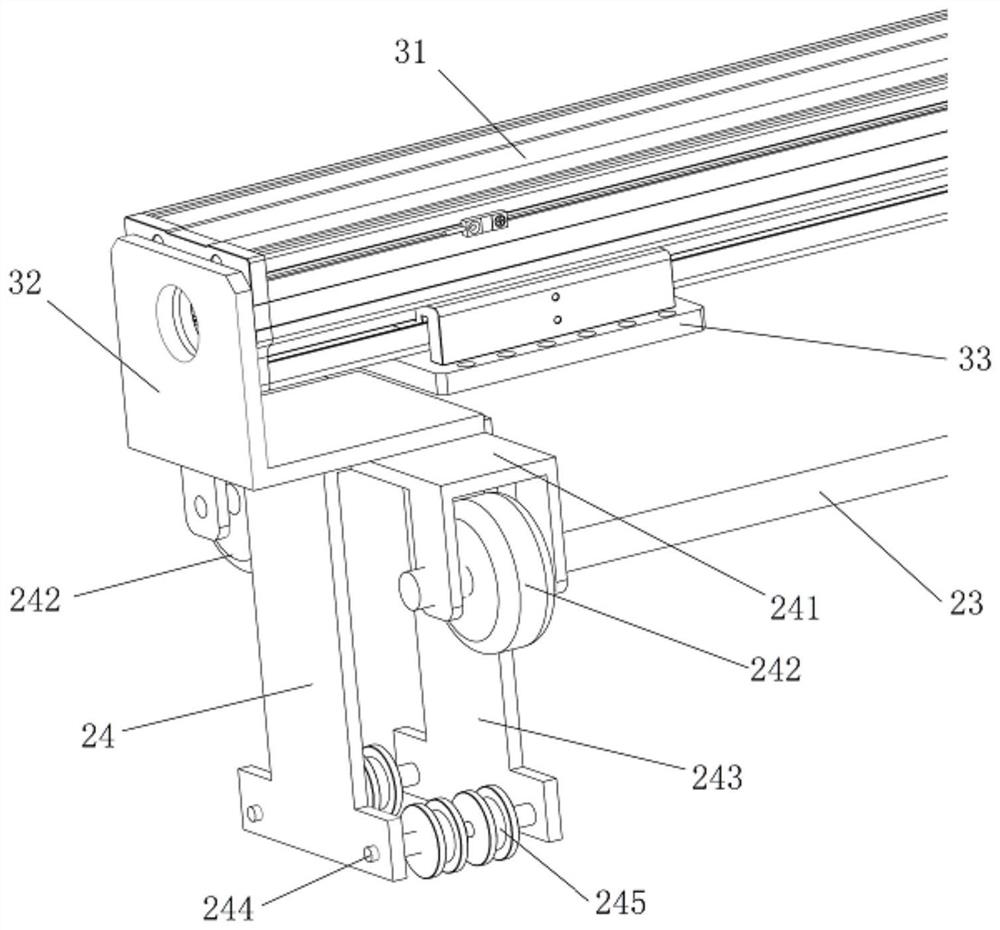

[0068] Left and right moving mechanism 2, one end is slidable and detachably mounted on the frame 1, and the other end is slidable and detachably mounted on the railway rail;

[0069] The front and rear moving mechanism 3 is detachably installed on the left and right moving mechanism 2;

[0070] The lifting mechanism 4 is detachably installed on the output end of the forward and backward moving mechanism 3;

[0071] Rotating breaking mechanism 5 is installed on the output end of lifting mechanism 4, and is driven by left and right moving mechanism 2, forward and backward moving mechanism 3 and lifting mechanism 4 to realize left and right, front and rear and up and down movement, and its front end is equipped with high pressure nozzle 56.

[0072] In this embodiment, the frame 1 is used to install the left and righ...

Embodiment 2

[0108] A double-sided breaking system for post-casting belts of ballastless track base plates, such as Figure 7 shown, including:

[0109] The water tank 61 is equipped with a water source for pressurization;

[0110] A high-pressure water pump 62, its water inlet end is connected to the water tank 61 through a water pipe, and the water in the water tank 61 is pressurized to become high-pressure water;

[0111] In the breaking device in embodiment 1, the water inlet end of the rotating breaking mechanism 5 of the breaking device is connected to the water outlet end of the high-pressure water pump 62 through a high-pressure water pipe, and the high-pressure water enters the rotating breaking mechanism 5 and then rotates and sprays out, and casts the belt after breaking;

[0112] The gas supply station 63 is connected to the left and right moving mechanism 2, the front and rear moving mechanism 3, and the rotating breaking mechanism 5 of the breaking device, and supplies air t...

Embodiment 3

[0116] A method for breaking both sides of the post-cast belt of a ballastless track base plate, comprising the following steps:

[0117] S1. Move each component of the breaking device to the side of the rear casting belt of the base plate of the ballastless track in pieces.

[0118] Specifically, the frame 1, the left and right moving mechanism 2, the front and rear moving mechanism 3, the lifting mechanism 4 and the rotating breaking mechanism 5 can be manually transported to the side of the back casting belt of the ballastless track base plate several times.

[0119] S2. Assemble two breaking devices, so that the two breaking devices are respectively installed on the two sides of the rear casting belt of the base plate of the ballastless track.

[0120] Such as figure 1 As shown, two breaking devices are assembled on both sides of the post-casting belt of the ballastless track base plate. According to the actual working space, the left and right moving mechanism 2 and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com