Fast production method of track beams different in size and shape

A manufacturing method and technology of track beams, which are applied to tracks, track maintenance, roads, etc., can solve problems such as hanging or blasting, crashing, interruption of straddle monorail traffic, etc., and achieve the effect of restoring operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

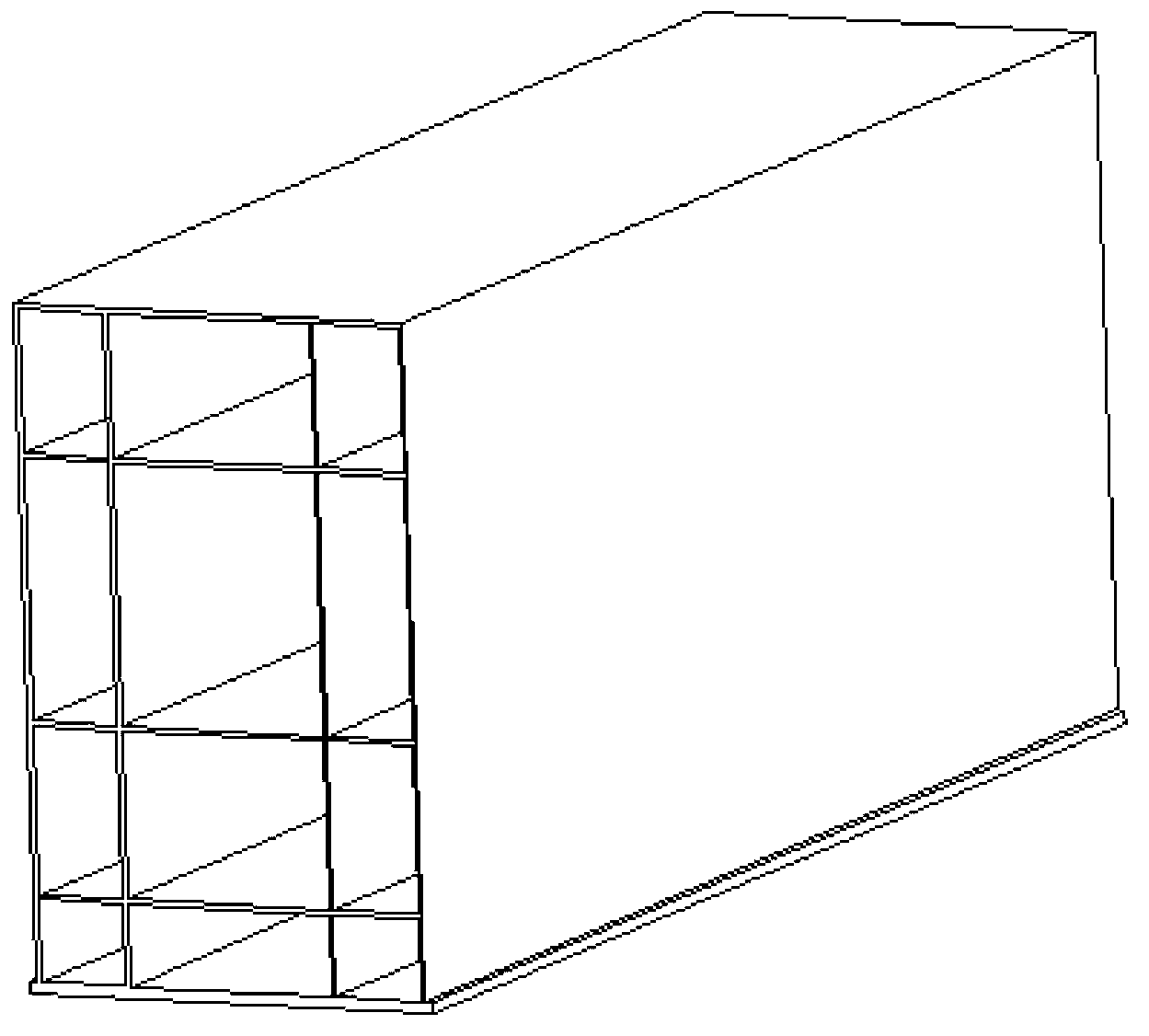

[0059] Example 1: Beam Length Realization Method 1

[0060] The method of realizing the length of the track beam: select prefabricated steel box segments (1) of different lengths + prefabricated connecting plates (2) of different gap lengths to adjust the length of the track beam.

[0061] The method described is applied to straight track beams such as Figure 12 . Linear prefabricated steel box segments such as figure 1 , the linear prefabricated connection plate such as Figure 5 . The length of the prefabricated steel box segment is l si , the number of segments is n; the gap length of the prefabricated connecting plate is Δ pi , then the actual track beam length l ac for:

[0062] l ac = Σ i = 1 n l si + Σ i = 1 ...

Embodiment 2

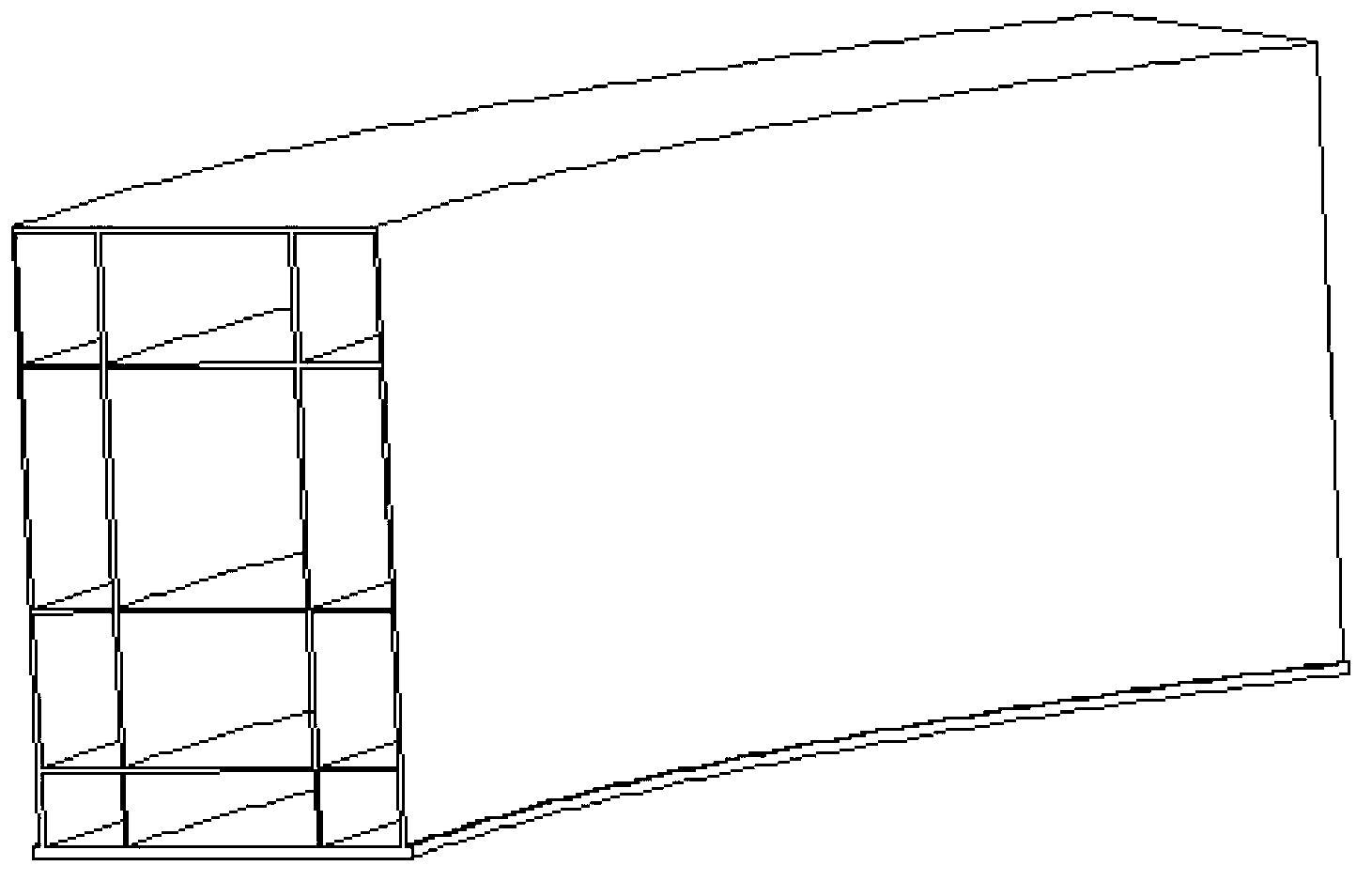

[0069] Example 2: Implementation Method 2 of Beam Length

[0070] The method of realizing the length of the track beam: select prefabricated steel box segments of different lengths (1) + prefabricated connecting plates of different gap lengths (2) + cast-in-place concrete of different thicknesses (3) to adjust the length of the track beam.

[0071] The method described is applied to straight track beams such as Figure 14 . Linear prefabricated steel box segments such as figure 1 , the linear prefabricated connection plate such as Figure 5 . The length of the prefabricated steel box segment is l si , the number of segments is n; the gap length of the prefabricated connecting plate is Δ pi , the thickness of the cast-in-place concrete at the beam end is Δ ci , then the actual track beam length l ac for:

[0072] l ac = Σ i = 1 n ...

Embodiment 3

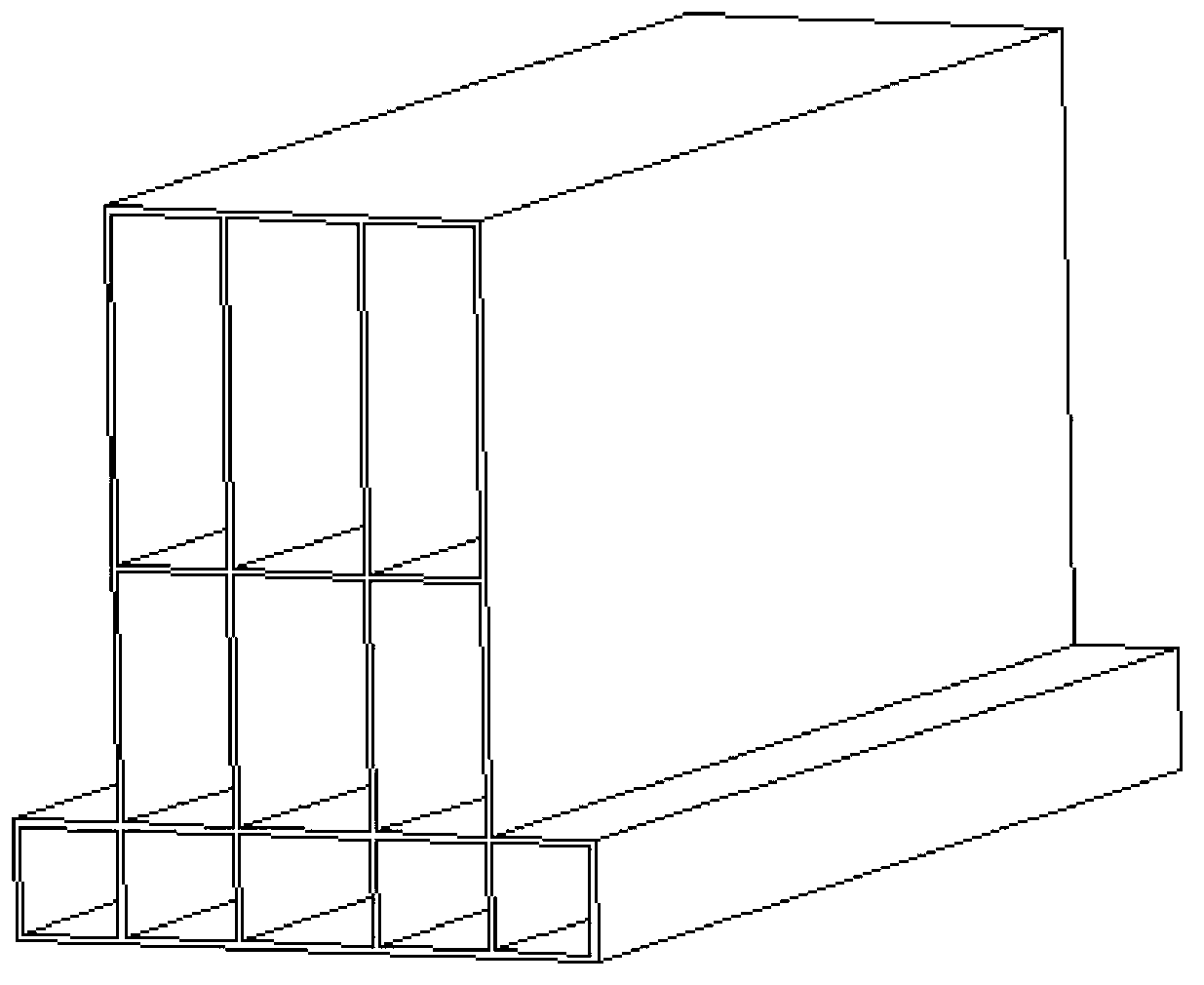

[0079] Embodiment 3: Beam height realization method one

[0080] The method of realizing the height of the track beam: select prefabricated steel box segments of different heights (1) + prefabricated metal contact surface structures of different heights (4) to adjust the height of the track beam.

[0081] The method is applied to steel box track beams, such as Figure 16 , Figure 17 .

[0082] The prefabricated steel box segments (1) have different heights, height h si The value range of is 500mm~2000mm; the prefabricated metal contact surface structure (4) has different heights, the height h mi The value range of is 0mm~500mm.

[0083] According to the target beam height, determine the height h of each prefabricated steel box segment si , and then according to the beam height of the track beam to be replaced and the superelevation value of the running surface, the height h of the prefabricated metal contact surface structure is determined by changing the height of the s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com