Method for constructing expansion joints of foundation in plate type ballastless track and templates for expansion joints

A slab ballastless track and expansion joint technology, applied in tracks, track maintenance, roads, etc., can solve problems such as construction difficulty, improve construction efficiency, ensure smoothness, and avoid misplaced platforms.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

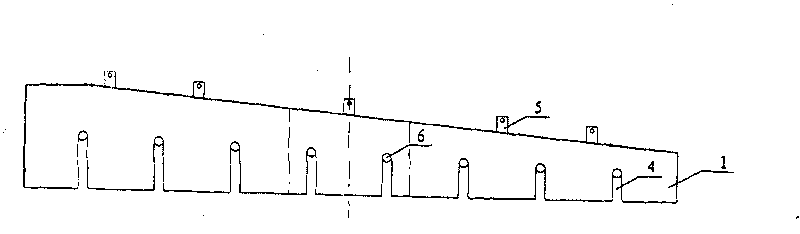

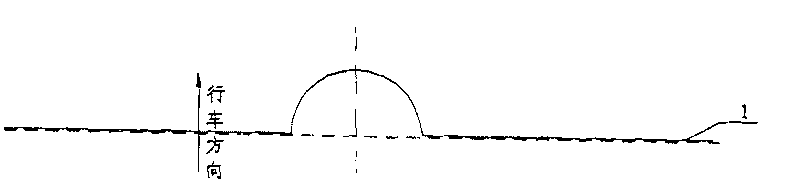

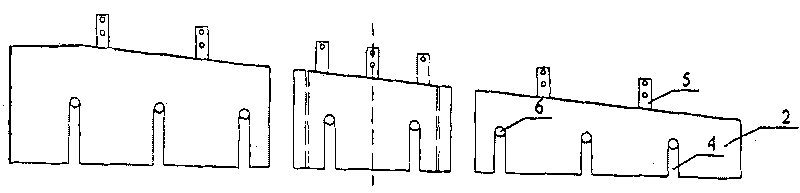

[0035] see Figure 1 to Figure 8 The expansion joint formwork of the plate-type ballastless track base shown is composed of three-layer formwork, the second-layer formwork 2 is located between the first-layer formwork 1 and the third-layer formwork 3, and keeps a distance from each other, the first-layer formwork Similar to the third-layer formwork, it is an upright steel plate with high left and low right and the middle part is equipped with a steel plate bent towards the driving direction. The lower part of the vertical steel plate is provided with multiple inverted "U"-shaped gaps ear plate 5;

[0036] The second layer formwork 2 is made up of three sections of erected steel plates with high left and low right and discontinuous. There is an inverted "U"-shaped notch 4, and at least two ear plates 5 are connected to the upper part.

[0037] The ear plate connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com