System and method for high-speed railway subgrade settlement restoration

A high-speed railway and repair system technology, applied in the direction of road, track, track maintenance, etc., can solve the problems of concrete support layer stress deformation, backfilling is not dense, damage, etc., to achieve the effect of meeting the operation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

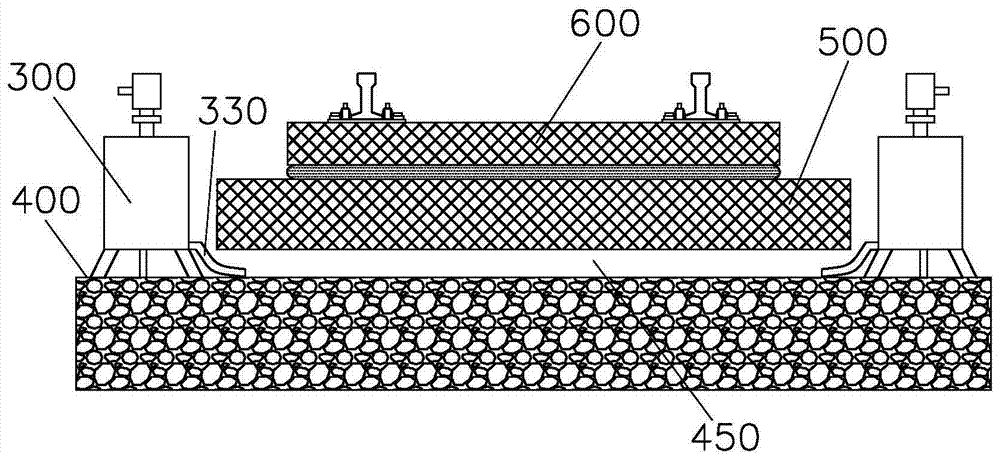

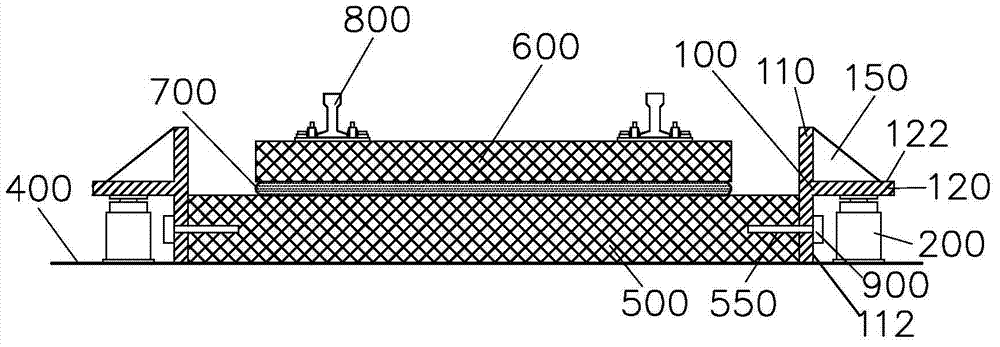

[0063] Next, the high-speed railway embankment settlement repair system of the present invention will be described in detail with reference to the accompanying drawings.

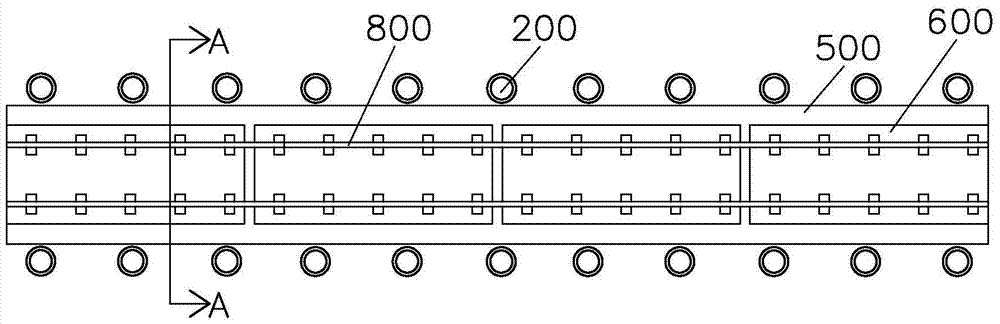

[0064] Please refer to Figure 1-Figure 5 , as a non-limiting example, the high-speed railway subgrade settlement repair system of the present invention includes twenty-two lifting components 100, twenty-two hydraulic jacking devices 200, hydraulic distribution equipment (not shown), an automatic control system ( not shown), eight grouting equipment 300.

[0065] In this non-limiting example, the base plate 500 carries a mortar layer 700 , a track slab 600 on the mortar layer 700 , and a steel rail 800 on the track slab 600 . Four track plates 600 are carried on the base plate 500 . Twenty-two hydraulic jacking devices 200 are symmetrically distributed on both sides of the base plate 500 at equal intervals.

[0066] Each lifting member 100 is arranged at a preset lifting point on the base plate 500 , each...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com