Railroad bed repair method without affecting existing running conditions

A technology of railway embankment and repair method, which is applied in the direction of road, infrastructure engineering, soil protection, etc. It can solve the problems of insufficient disease control ability, increased construction period, long construction period, etc., and achieves improved waterproof and drainage capabilities and low labor intensity. , The effect of short construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

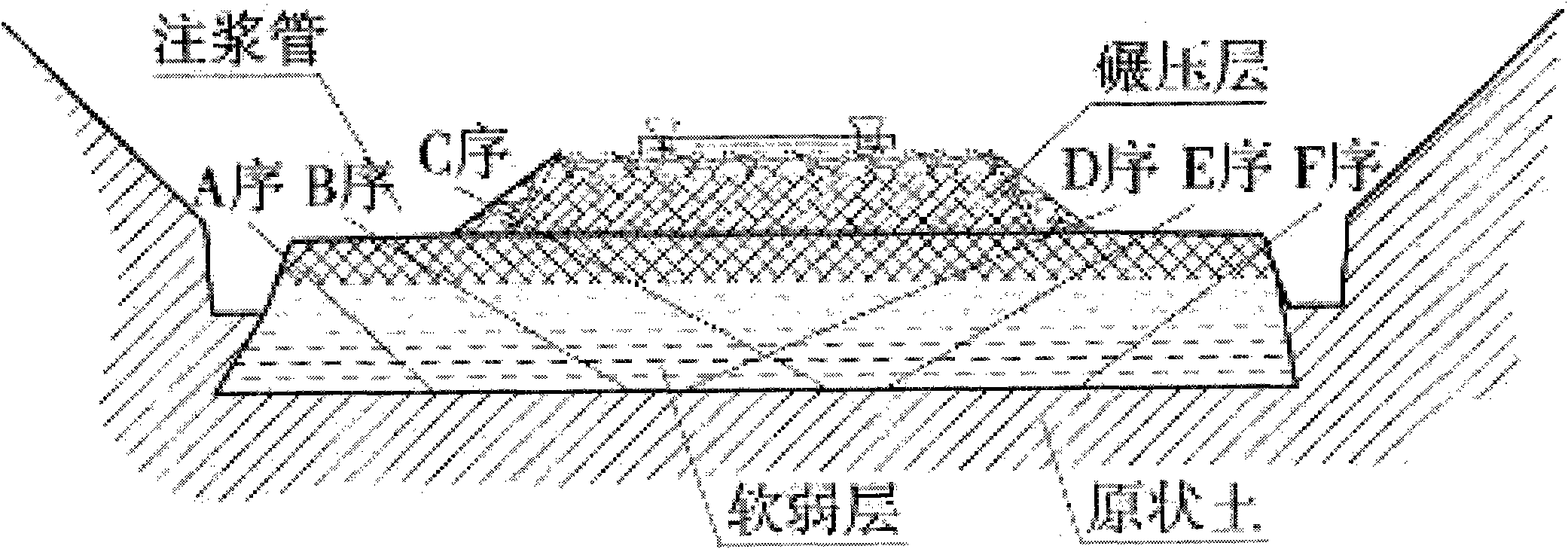

[0016] In the embodiment of the present invention, in order not to affect the conditions of railway trains, grouting is used for the diseased section of the roadbed, and the grout is injected into the soil of the roadbed, and the cracks between the soil particles are discharged by filling, compacting and infiltration. Water and air occupy their space, improve the mechanical properties of the original roadbed, reduce the porosity of the roadbed soil, and increase the strength.

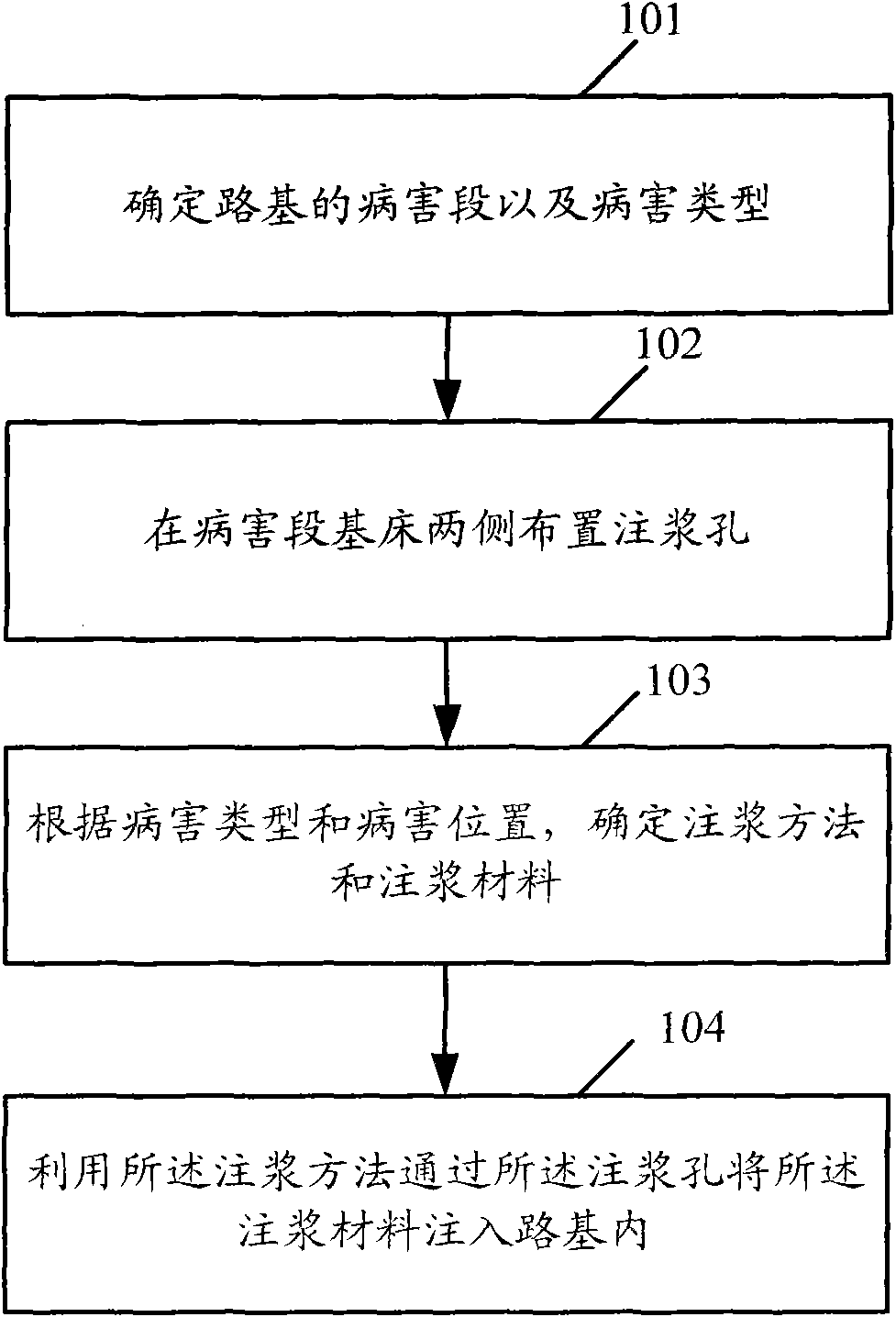

[0017] See figure 1 As shown, the method of the embodiment of the present invention specifically includes the following steps:

[0018] Step 101: Determine the location of the diseased section of the roadbed and the disease type.

[0019] Use geological radar method and / or electrical method to conduct non-destructive detection of existing railway subgrade to determine the location and type of diseased section of the subgrade. Furthermore, detailed inspections can be repeated on the diseased segment determined...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com