A gray soil anti-osmotic film-mixing wall combined with the foundation structure and design method

An anti-seepage membrane and mixing wall technology, which is applied in basic structure engineering, sheet pile wall, soil protection and other directions, can solve the problems of high cost, high site requirements, long construction period, etc., to improve the effect of waterproofing and drainage, and ensure reliability. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The combined foundation structure and design method of a lime-soil anti-seepage membrane-stirring wall of the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

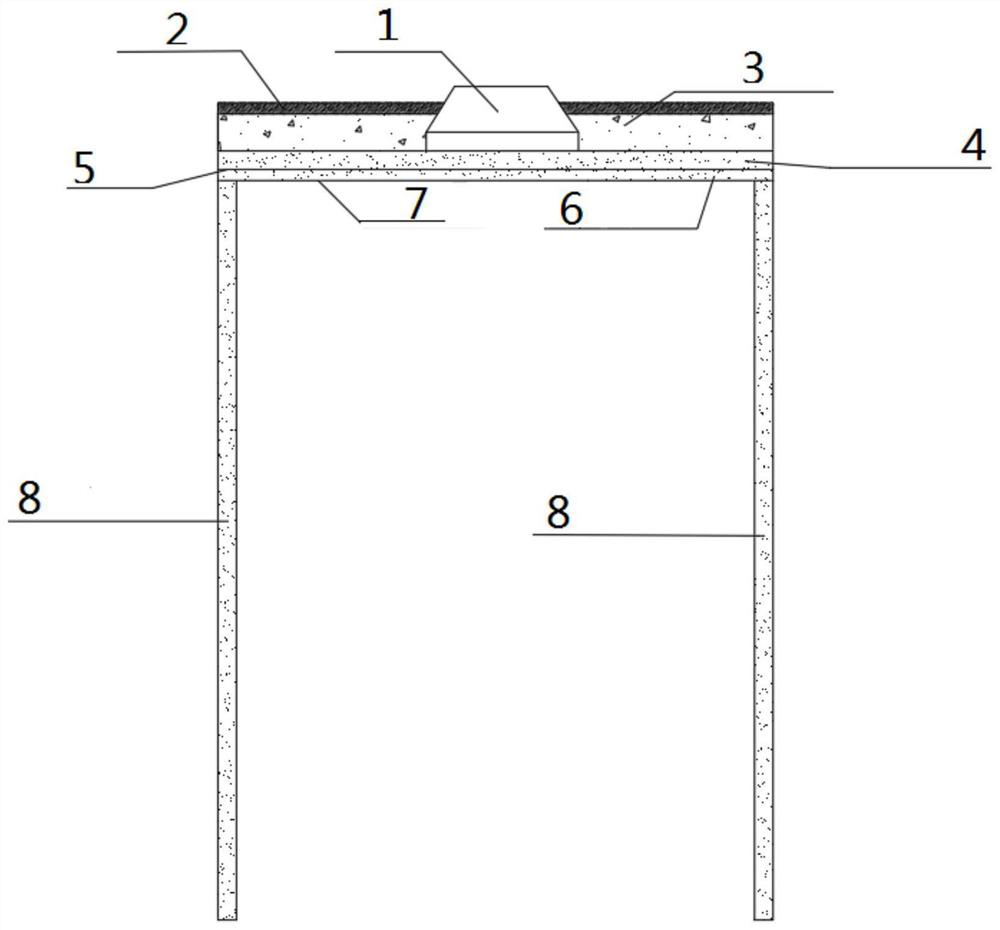

[0025] like figure 1 and figure 2 As shown in the figure, a combined foundation structure and design method of lime-soil anti-seepage membrane-stirring wall includes a field flat sealing layer 2, a plain soil layer 3, a first lime-soil layer 4, and a first anti-seepage membrane that are sequentially arranged along the foundation 1 to the ground. 5. The second lime soil layer 6 and the second anti-seepage membrane 7, the second anti-seepage membrane 7 is provided with a stirring wall 8 along the underground direction;

[0026] The design method specifically includes the following steps:

[0027] Step 1: Design the ground sealing layer according to the requirements of collapsible loess field flat sealing, determine the burial depth of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com