Asphalt graded broken stone for high-speed railway foundation bed and production method thereof

A technology of graded crushed stone and production method, which is applied to roads, roads, on-site coagulation pavement, etc., can solve the problems of inability to meet the functional requirements of high-speed railway asphalt graded crushed stone bed, lack of production methods, etc. Achieve good waterproof and impermeability, improve water-proof and drainage capabilities, and good high-temperature anti-deformation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

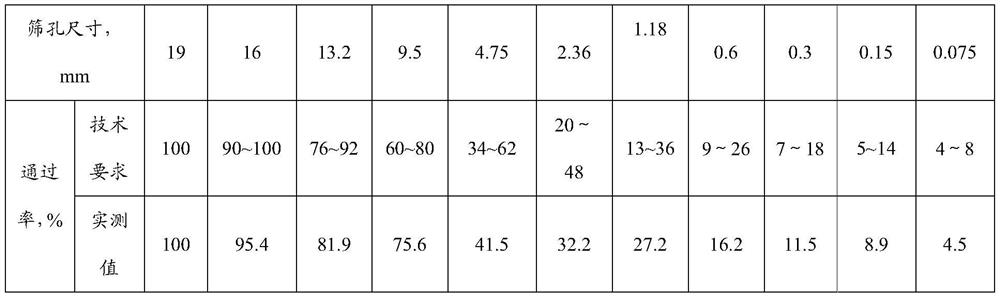

[0038] According to the following steps to prepare asphalt graded macadam with the specification of AGCS-16:

[0039] (1) Classify and preheat the SBS modified asphalt in the storage tank to 180°C for 6 hours;

[0040] (2) heating the aggregate to a temperature of 200°C, and drying the aggregate so that the residual water content of the aggregate is 0.1%;

[0041] (3) The aggregate is dry-mixed with a batch mixer, the dry-mixing time is 10s, and the dry-mixing temperature is 180°C;

[0042] (4) Add limestone powder, asphalt reinforcing agent and preheated SBS modified asphalt to the aggregate after dry mixing in step (3), and mix for 50 seconds.

[0043] (5) Produce and obtain asphalt graded gravel for high-speed railway bed.

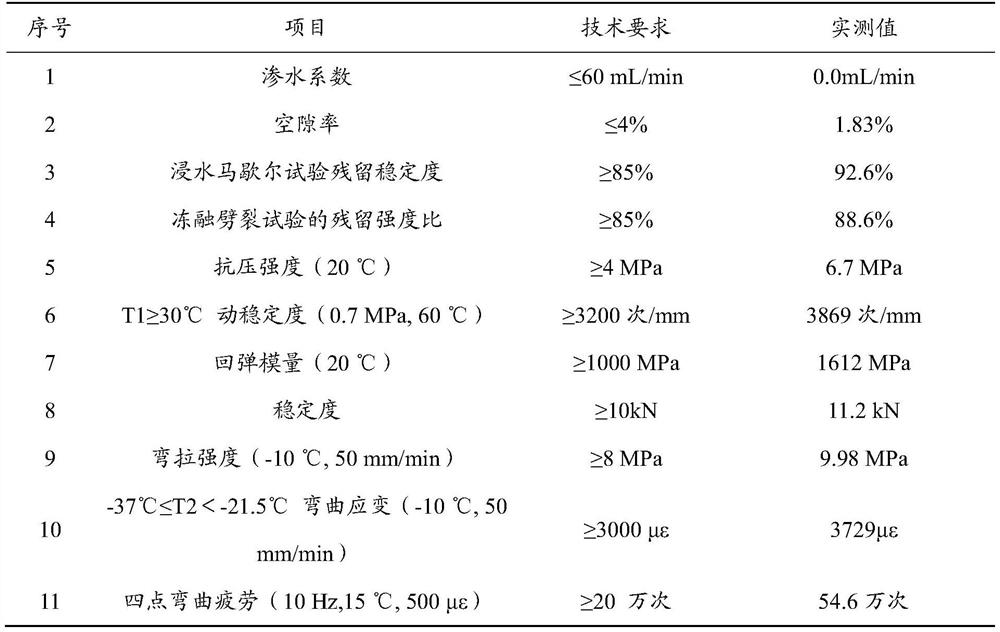

[0044] The composition of asphalt graded macadam whose specification is AGCS-16 is: based on the total mass of asphalt graded macadam of high-speed railway subgrade, 90.0% of aggregate, 4.5% of limestone powder, 5.0% of SBS modified asphalt, and aspha...

Embodiment 2

[0053] Follow the steps below to prepare asphalt graded macadam with the specification of AGCS-20:

[0054] (1) Classify and preheat the SBR modified asphalt in the storage tank to 160°C for 3 hours;

[0055] (2) heating the aggregate to a temperature of 180°C, and drying the aggregate so that the residual water content of the aggregate is 0.6%;

[0056] (3) The aggregate is dry-mixed with a batch mixer, the dry-mixing time is 15s, and the dry-mixing temperature is 170°C;

[0057] (4) Add limestone powder, asphalt reinforcing agent and preheated SBR modified asphalt to the dry-mixed aggregate in step (3), and mix for 55 seconds.

[0058] (5) Produce and obtain asphalt graded gravel for high-speed railway bed.

[0059] The composition of asphalt graded macadam whose specification is AGCS-20 is: based on the total mass of asphalt graded macadam of high-speed railway subgrade, 89.0% of aggregate, 5.2% of limestone powder, 4.8% of SBR modified asphalt, and asphalt reinforcing ag...

Embodiment 3

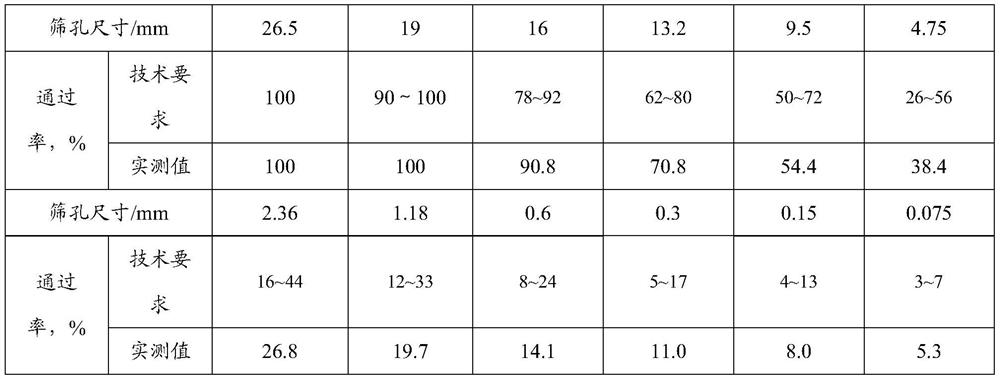

[0068] Prepare asphalt graded macadam with specification AGCS-25 according to the following steps:

[0069] (1) Classify and preheat the SBS modified asphalt in the storage tank to 175°C for 5 hours;

[0070] (2) heating the aggregate to a temperature of 185° C., and drying the aggregate so that the residual water content of the aggregate is 0.3%;

[0071] (3) The aggregate is dry-mixed by a batch mixer, the dry-mixing time is 15s, and the dry-mixing temperature is 180°C;

[0072] (4) Add limestone powder, asphalt reinforcing agent and preheated SBS modified asphalt to the aggregate after dry mixing in step (3), and mix for 50 seconds.

[0073] (5) Produce and obtain asphalt graded gravel for high-speed railway bed.

[0074] The composition of asphalt graded macadam whose specification is AGCS-25 is: based on the total mass of asphalt graded macadam for high-speed railway subgrade, 90.2% of aggregate, 4.5% of limestone powder, 4.6% of SBR modified asphalt, and asphalt reinfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com