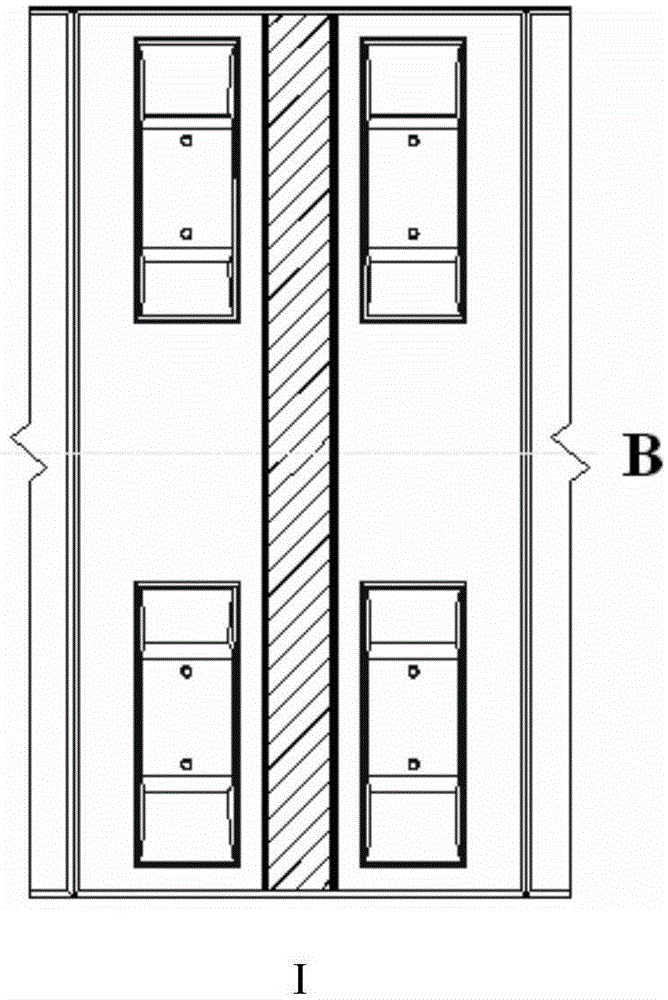

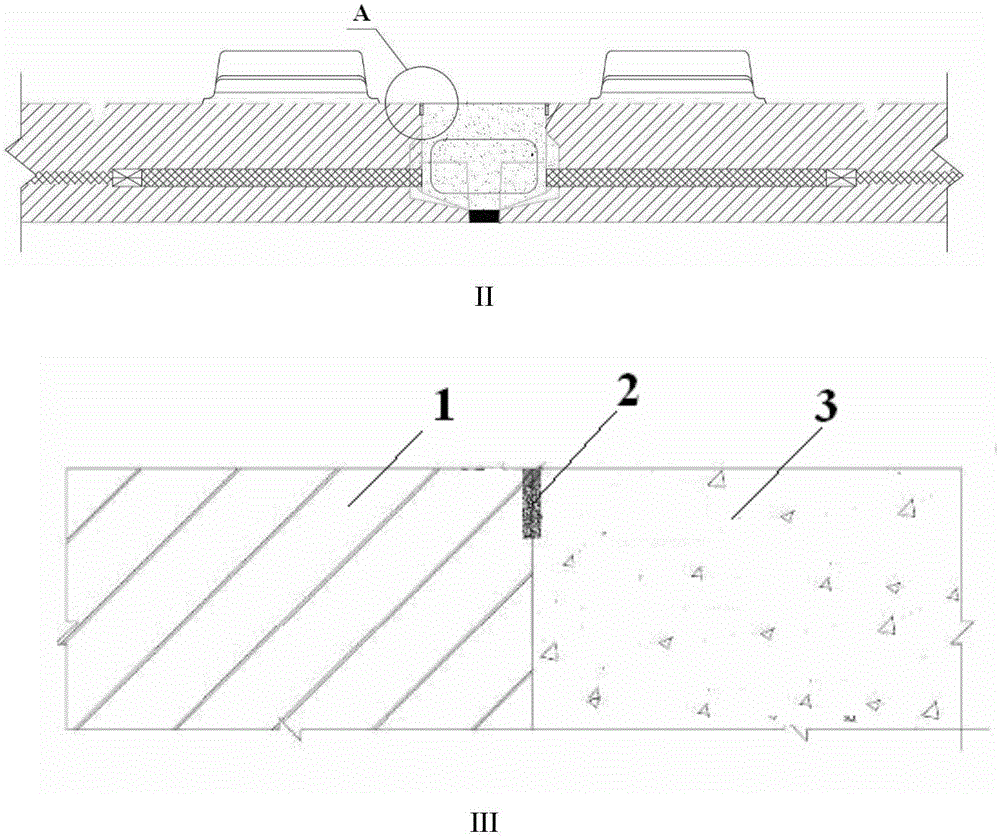

Method for treating cracks at seam positions of CRTS II ballastless track plates

A slab ballastless track and joint technology, which is used in tracks, track maintenance, roads, etc., to prevent aging, reduce repair difficulty, and achieve good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

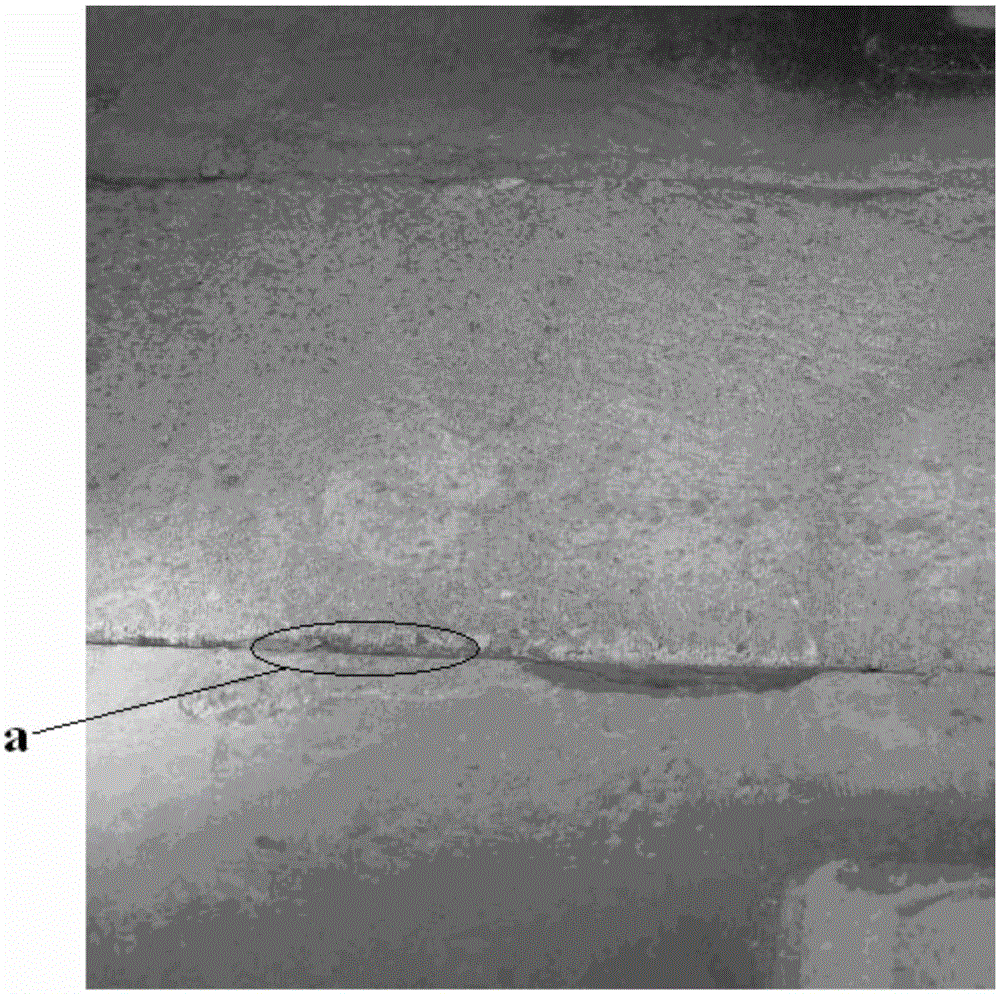

[0037] A wide joint crack repair operation was carried out on the site of a CRTSII slab ballastless track for passenger trains. The crack width was 0.3mm and the working temperature was 20°C. First, use a manual cutting machine to cut a crack with a width of 5 mm and a depth of 20 mm along the crack between the old and new concrete; remove the solid particles inside the cut, rinse with water, and blow dry. After cleaning, glue on both sides of the crack. Paste anti-pollution tape with a spacing of about 15mm; inject low-viscosity polyurethane material into the crack with a glue gun to a filling height of about 15mm; after drying, inject high-viscosity silicone waterproof material into the crack, and then smooth the high-viscosity silicone material, peel off the anti-pollution tape, and the repair is complete.

[0038] The invention is suitable for on-site operation requirements of high-speed railway skylights, requires simple tools, convenient, fast and economical construction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com