Compound cave making method of open hole of coalbed gas well

A coalbed methane well and cavitation technology, which is applied to drilling equipment and methods, liquid/gas jet drilling, drilling equipment, etc., can solve the problems of reducing the operating intensity of mechanical cavitation tools, so as to reduce operational risks and meet high-efficiency mining , Operational safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

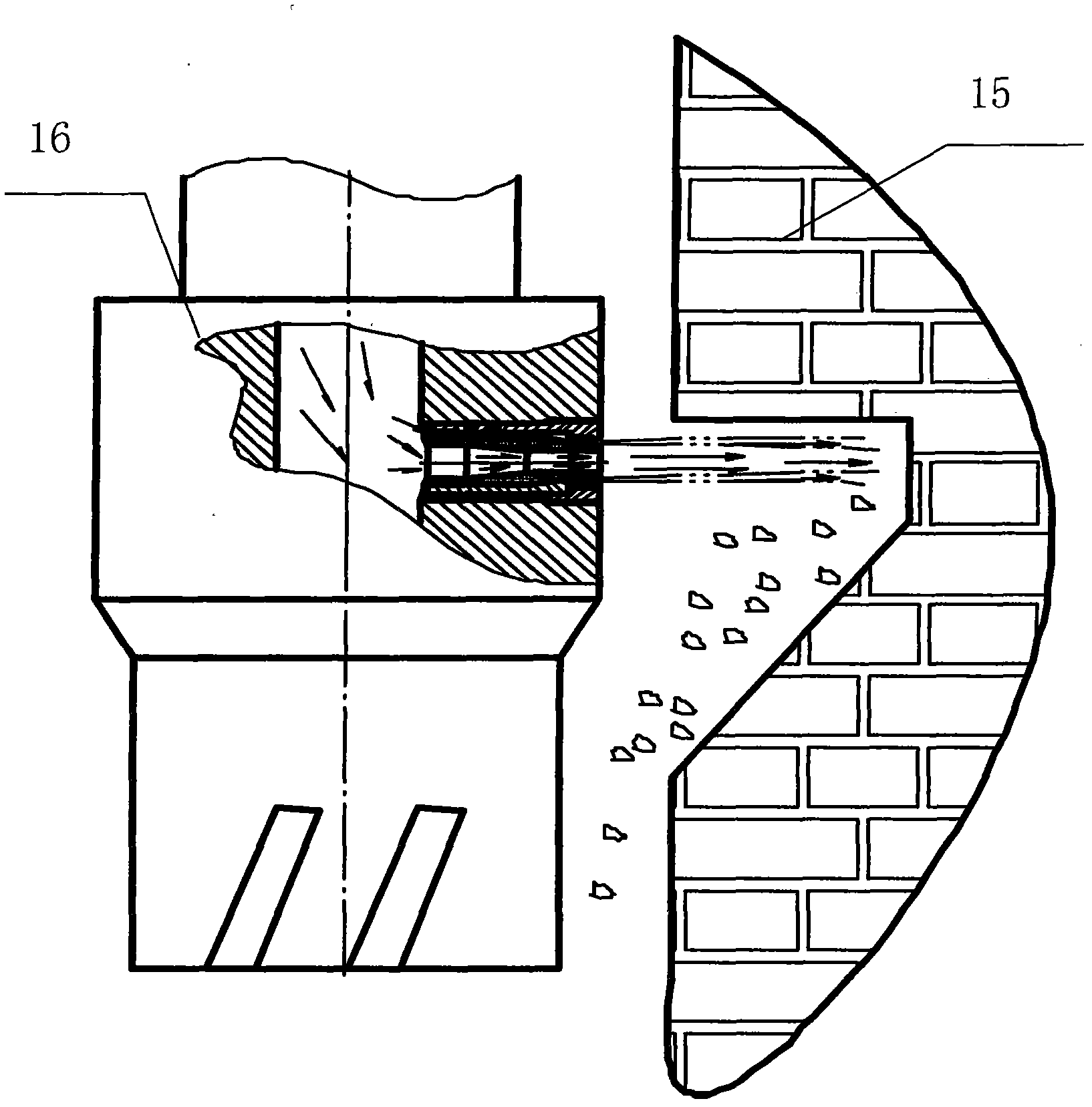

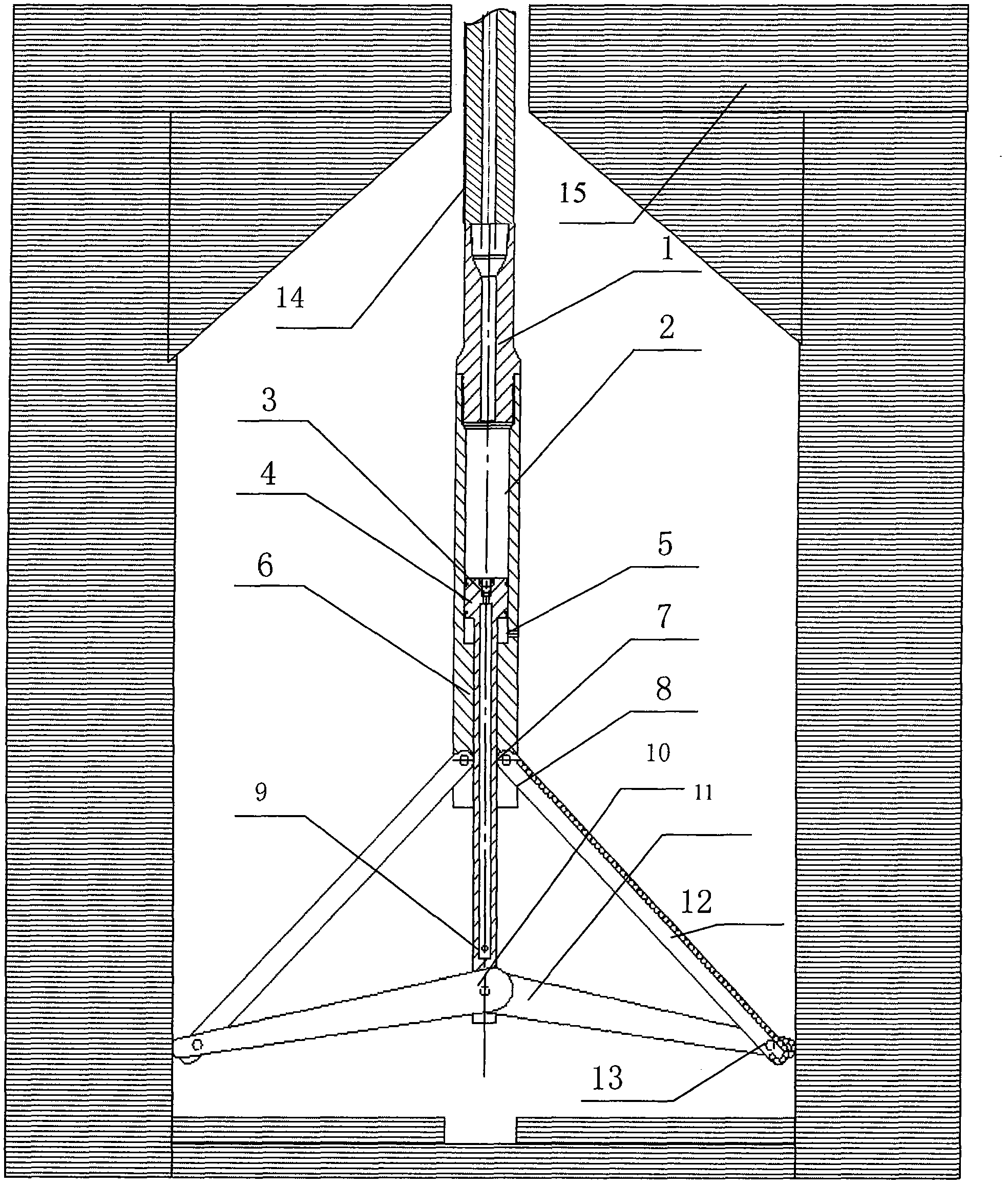

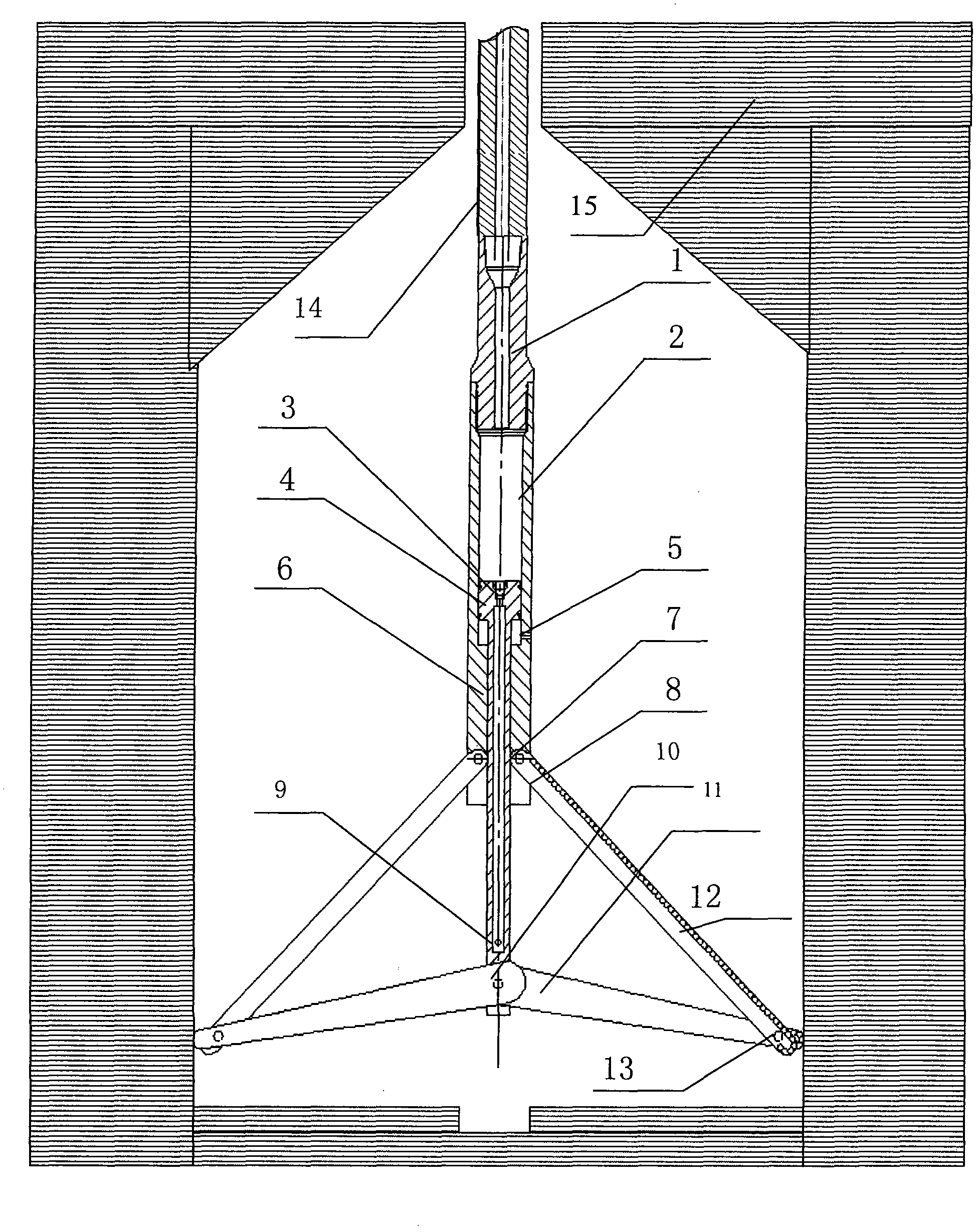

[0028] Taking the D 152 main wellbore as an example below, the open-hole composite cavitation method for coalbed methane wells of the present invention will be further described in conjunction with the accompanying drawings, which mainly includes the following steps:

[0029] The first step, preparation, cleaning and testing of hydrojet tools in the open hole section of coalbed methane well

[0030] Determine the depth and location of the cave in the open hole section of the coal seam, that is, the top and bottom positions of the cave section; use the conventional coal seam drilling method to drill through the coal seam, and the casing is lowered to the top of the open hole section where the coal seam section is made, and the coal seam borehole is drilled by circulation. The cuttings and coal cuttings are cleaned up, the wellbore is smooth and free of falling objects, and there is no plugging of cuttings and sand to ensure that the cavitation tool can reach the bottom of the we...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com