Geopolymer-based mold-proof antibacterial interior wall coating and preparation method thereof

An anti-mildew and antibacterial, interior wall coating technology, used in anti-fouling/underwater coatings, coatings, paints containing biocides, etc. Odor and other problems, to improve the anti-sag performance, reduce pollution, prevent water loss and cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

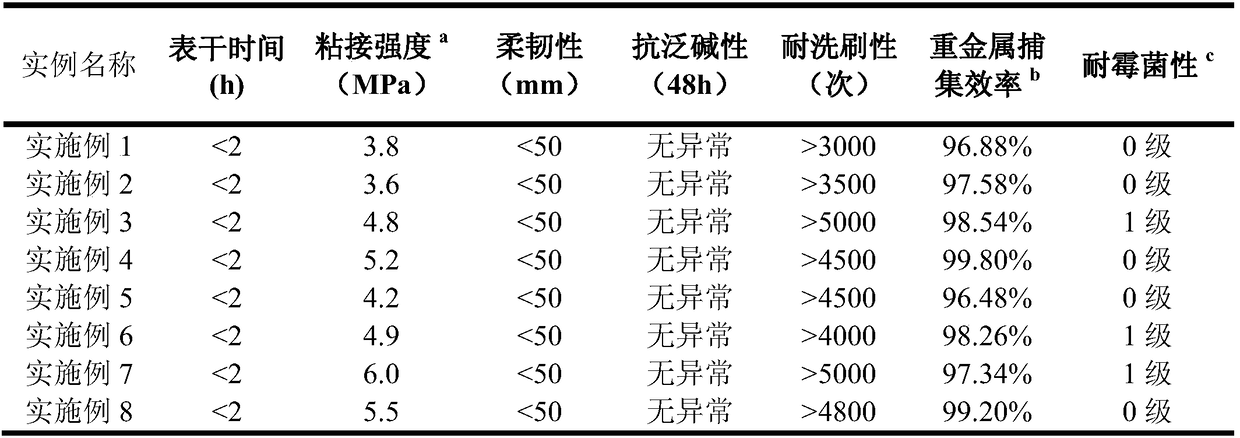

Examples

Embodiment 1

[0041] 10 parts by weight of metakaolin, 2 parts by weight of nano-zinc, 2.5 parts by weight of nano-silver, 0.5 parts of nano-titanium dioxide, 2 parts by weight of titanium dioxide, 71 parts by weight of quartz powder, 3 parts by weight of sodium polyacrylate, 1 part by weight of The sodium salicylate of 1 weight part, the sodium hypophosphite of 1 weight part, the chopped glass fiber of 2 weight parts, the carbon fiber of 2 weight parts, the boron fiber of 1 weight part, the fumed silica R812 of 2 weight parts mix and stir to obtain Solid phase S: 20 parts by weight of sodium water glass (modulus 1.0), 0.5 parts by weight of lithium oxide, 0.5 parts by weight of lithium hydroxide, 1 part by weight of guar gum, 3 parts by weight of nonylphenol Oxyethylene ether and 75 parts by weight of water were mixed and stirred uniformly to obtain a liquid phase L. When in use, mix and stir the solid phase S and the liquid phase L in a weight ratio of 100:40 to obtain a geopolymer-base...

Embodiment 2

[0043] With the metakaolin of 10 parts by weight, the fly ash of 1 part by weight, the chitosan of 2 parts by weight, the lithopone of 5 parts by weight, the ground calcium carbonate powder of 80 parts by weight, the vinylsulfonic acid of 0.1 part by weight Sodium, the basalt fiber of 0.5 weight part, the silica fiber of 1 weight part, the fumed silica R812 of 0.4 weight part are mixed and stirred to obtain solid phase S; The sodium water glass (modulus 1.5) of 5 weight parts, 0.5 weight part The sodium oxide of part, the sodium hydroxide of 0.5 part by weight, the guar gum of 3 parts by weight, the carrageenan of 0.8 part by weight, the polydimethylsiloxane of 0.2 part by weight, the water mixing and stirring of 90 parts by weight obtains liquid phase L. When in use, mix and stir the solid phase S and the liquid phase L in a weight ratio of 100:80 to obtain a geopolymer-based anti-mildew and antibacterial interior wall coating.

Embodiment 3

[0045]With the kaolin of 80 parts by weight, the slag of 7 parts by weight, the thymol of 1 part by weight, the salicylanilide of 1 part by weight, the strontium yellow of 1 part by weight, the ground calcium carbonate of 5 parts by weight, the Secondary sodium alkyl sulfonate, 1.5 parts by weight of tetrasodium edetate, 1 part by weight of boron carbide fiber, 0.5 part by weight of boron nitride fiber, and 1 part by weight of fumed silica R812 are mixed and stirred evenly to obtain a solid phase S; With 90 parts by weight of potassium silicate (modulus 1.5), the potassium oxide of 1 part by weight, the potassium hydroxide of 0.5 parts by weight, the sodium polystyrene sulfonate of 3 parts by weight, the sodium polyacrylate of 3 parts by weight, 0.5 parts by weight of polyoxyethylene polyoxypropanolamine ether and 2 parts by weight of water were mixed and stirred uniformly to obtain a liquid phase L. When in use, mix and stir the solid phase S and the liquid phase L in a weigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com