Electroosmosis electrode and electroosmosis draining system thereof

A drainage system and electroosmosis technology, applied in soil protection, construction, infrastructure engineering, etc., can solve the problems of short-term horizontal seepage to vertical pipes, the stability of upper buildings, and steel pipes being easily corroded, etc. The effect of ensuring long-term stability and safety, avoiding impact damage and simplifying construction procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

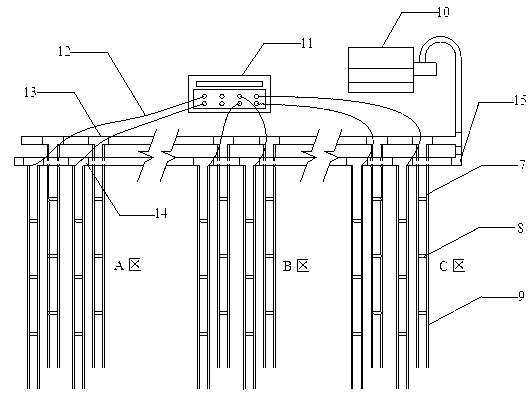

[0023] The present invention will be further described below in conjunction with the accompanying drawings.

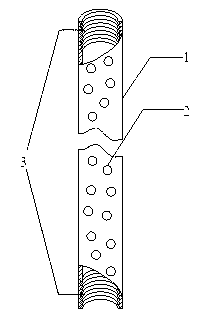

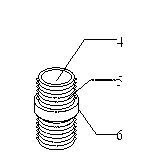

[0024] like figure 1 and figure 2As shown, the electroosmotic electrode of the present invention includes a segmented drainage electrode tube 7 , a flexible conductive joint 8 and a conductive filter cloth 9 . The segmented drainage electrode tube 7 is made of graphite material with excellent corrosion resistance and reasonable price. Considering the requirements for the strength and toughness of electroosmotic electrodes in engineering practice, as well as the high strength, poor toughness and plasticity of graphite materials, etc. performance, the electroosmotic electrode 7 is made into sections with a length ranging from 2 to 4 m to meet the requirements of transportation and construction. At the same time, the sectioned drainage electrode tube 7 is coated with graphite electrode antioxidant 1 to further improve the electrode quality. corrosion resistance...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com