Hydrophilic antistatic polypropylene composition and preparation method and application thereof

A polypropylene composition and antistatic technology, applied in the manufacture of conductive/antistatic filaments, single-component polyolefin rayon, non-woven fabrics, etc., can solve the problem of reducing the mechanical properties of products and adding a large amount of hydrophilic agent and other problems, to achieve the effects of accelerated diffusion performance, short penetration time, and good hydrophilicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

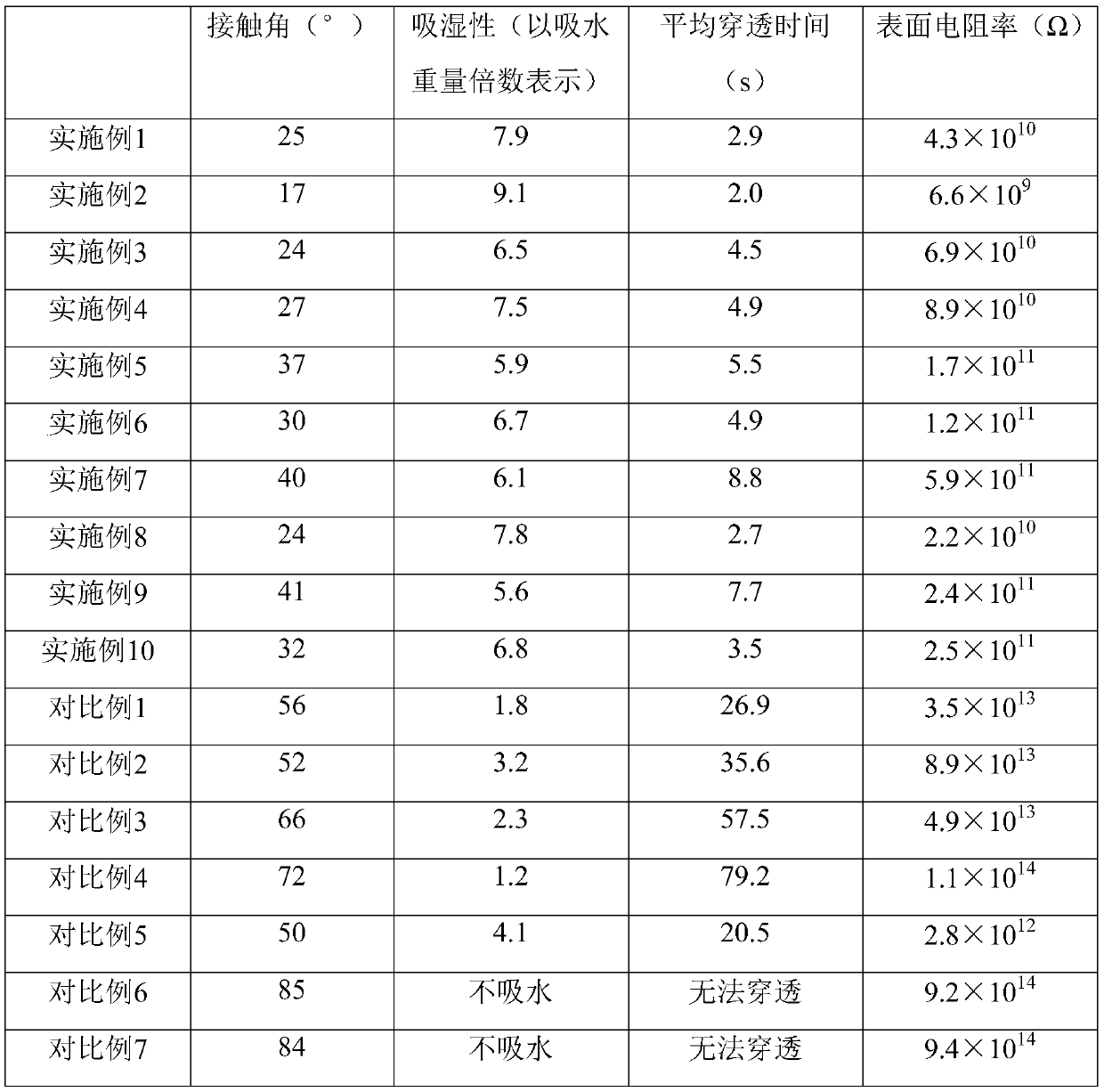

Examples

Embodiment 1

[0038] The raw material of the hydrophilic antistatic material includes the following components by weight:

[0039] Powder homopolymer polypropylene (MI=60g / 10min) 50 parts

[0040] Compatibilizer: 5 parts of ethylene-methyl acrylate-glycidyl methacrylate copolymer (Arkema AX8900, France)

[0041] Dispersant: 5 parts of silica

[0042] Lubricant: 0.8 parts of monoglyceride

[0043] Hydrophilic accelerator: dodecatriol (based on carbon chain distribution, the ratio of dodecanol to tetradecyl alcohol is 7:3) 5 parts

[0044] Non-ionic surfactant: isomeric tridecanol polyoxyethylene ether (average number of moles of EO is 5, HLB=11.5) 20 parts

[0045] Anionic surfactant: 14 parts of sodium secondary alkyl sulfonate

[0046] Antioxidant 168 0.1 parts

[0047] Antioxidant 1010 0.1 parts.

[0048] Preparation Process:

[0049] Mix polypropylene, dispersant and hydrophilic accelerator in a high-speed mixer. Add compatibilizer and hydrophilic agent (nonionic surfactant and anionic surfactant) durin...

Embodiment 2

[0052] The hydrophilic antistatic material is prepared according to the preparation method of Example 1, except that the following components are included in parts by weight:

[0053] Powder homopolymer polypropylene (MI=60g / 10min) 30 parts

[0054] Granular homopolymer polypropylene (MI=1200g / 10min) 20 parts

[0055] Compatibilizer: ethylene-methyl acrylate-glycidyl methacrylate copolymer (from French Arkema, model AX8900) 4 parts

[0056] Dispersant: 1 part of silica

[0057] Lubricant: Erucamide 0.8 parts

[0058] Hydrophilic accelerator: dodecatriol (based on carbon chain distribution, the ratio of dodecanol to tetradecanol is 7:3) 10 parts

[0059] Non-ionic surfactant: isomeric tridecanol polyoxyethylene ether (average number of moles of EO is 5, HLB=11.5) 20 parts

[0060] Anionic surfactant: 14 parts of sodium dodecylbenzene sulfonate

[0061] Antioxidant 168 0.1 parts

[0062] Antioxidant 1010 0.1 parts.

Embodiment 3

[0064] The hydrophilic antistatic material is prepared according to the preparation method of Example 1, except that the following components are included in parts by weight:

[0065] Powder homopolymer polypropylene (MI=60g / 10min) 30 parts

[0066] Granular homopolymer polypropylene (MI=800g / 10min) 10 parts

[0067] Compatibilizer: ethylene-acrylic acid copolymer (from DuPont, USA, model 2022) 10 parts

[0068] Dispersant: 1 part of sodium sulfate

[0069] Lubricant: Erucamide 0.8 parts

[0070] Hydrophilic accelerator: 10 parts of dibenzylidene sorbitol

[0071] Non-ionic surfactant: isomeric deca alcohol polyoxyethylene ether (average number of moles of EO is 5, HLB=13.2) 20 parts

[0072] Anionic surfactant: 18 parts of sodium secondary alkyl sulfonate

[0073] Antioxidant 412S 0.1 part

[0074] Antioxidant 245 0.1 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com