Inorganic film tube and making method thereof

An inorganic membrane and inorganic additive technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve problems such as unsatisfactory effect of dust removal and purification in environmental protection sewage treatment, difficult manufacturing technology, and difficulty in forming and processing. , to achieve the effect of rapid purification operation, smooth surface and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

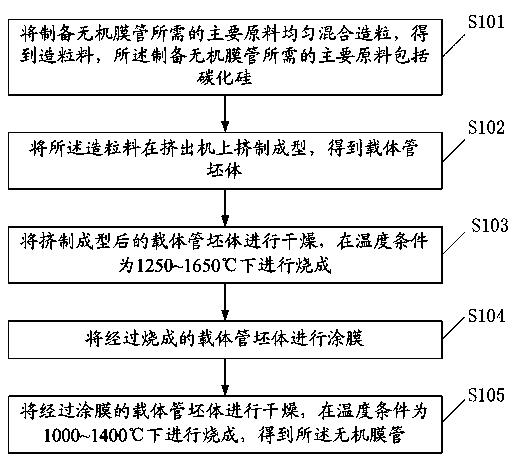

[0096] Correspondingly, as figure 1 As shown, the embodiment of the present invention provides a method for preparing an inorganic membrane tube, which includes the following steps in sequence:

[0097] S101, uniformly mixing and granulating main raw materials required for preparing inorganic membrane tubes to obtain granulated material, wherein the main raw materials required for preparing inorganic membrane tubes include silicon carbide.

[0098] It should be noted that the granulated material is a plastic material.

[0099] Wherein, the main raw material formula of the inorganic membrane tube in weight percentage is as follows:

[0100] Silicon carbide 45~90%;

[0101] Inorganic additives 0~85%;

[0102] Binder 0~6%;

[0103] Plasticizer 0~2%;

[0104] Porogen 0~7%;

[0105] Water 5~25%;

[0106] The inorganic additive is SiO 2 、Al 2 o 3 , one or a combination of kaolin;

[0107] The binder is one or a combination of carboxymethyl cellulose, polyvinyl alcohol, ...

Embodiment 1

[0137] Selected raw material formula: wt%

[0138] SiC 70;

[0139] SiO 2 10;

[0140] Al 2 o 3 10;

[0141]Kaolin 10 .

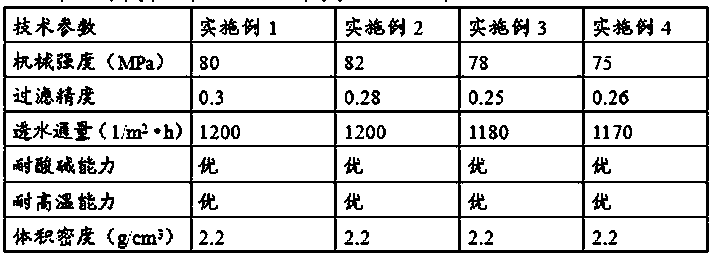

[0142] After mixing evenly, add 1-2wt% carboxymethyl cellulose, 1-2wt% modified starch, 0.5wt% glycerin, 1-5wt% sawdust, 20-25wt% water and stir evenly, and granulate into plastic material on the granulator , and then extruded on an extrusion molding machine into a 19-hole channel carrier tube blank with an outer diameter of Ф30mm and an inner diameter of Ф4mm. After drying, it is fired in a gas shuttle kiln at a firing temperature of 1350~1450°C The back carrier tube body is coated with 0.2μm Al 2 o 3 After the membrane is dried, the membrane is fired at a temperature of 1100-1300°C to obtain an inorganic membrane tube.

[0143] This product is suitable for sewage treatment and filtration in the field of environmental protection.

Embodiment 2

[0145] Selected raw material formula: wt%

[0146] SiC 80 ;

[0147] SiO 2 5;

[0148] Al 2 o 3 5;

[0149] Kaolin 10.

[0150] After mixing, add 1-2wt% carboxymethyl cellulose, 1-2wt% modified starch, 0.5wt% glycerin, 1-5wt% sawdust, 20-25wt% water and stir evenly, then granulate into plastic material on the granulator , and then extruded on an extrusion molding machine into a single-hole channel carrier tube body with an outer diameter of Ф40mm and an inner diameter of Ф30mm. After drying, it is fired in a gas shuttle kiln at a firing temperature of 1350~1450°C Afterwards, the carrier tube body is coated with a 1 μm SiC film, and the film is fired at a temperature of 1100-1300 ° C to obtain an inorganic film tube.

[0151] This product is suitable for the filtration and separation of high-temperature flue gas, the purification and purification of air in certain specific environments, etc.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com