Comprehensive anticorrosive method of metal pipe fitting

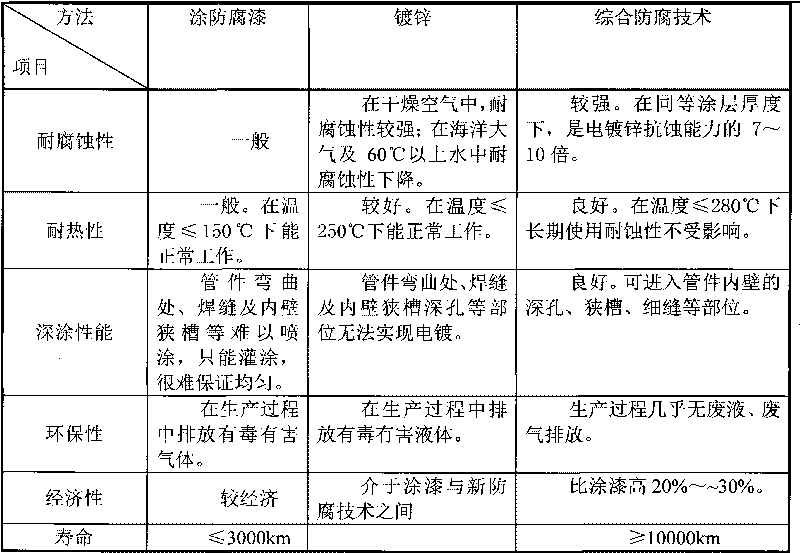

A metal pipe fitting and surface composite technology, applied in metal material coating process, coating, hot dip plating process, etc., can solve the problems of poor adhesion of anti-corrosion layer on the surface of vehicle pipeline, and achieve good generalizability and adhesion. Strong, economical and environmentally friendly results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] In the present invention, the metal pipe fittings that need to be processed are sequentially carried out in the following steps:

[0020] 1. Degreasing and rust removal;

[0021] (1) High-temperature sintering: put the metal pipe fittings in a zinc-chromium-coated baking furnace, adjust the furnace temperature to 300-320°C, and bake for 20 minutes.

[0022] (2) Mechanical shot blasting: Put the metal pipe fittings in the shot blasting machine for 5 minutes.

[0023] 2. Composite phosphating:

[0024] Put the metal pipe fittings after step 1 in the compound phosphating solution with a temperature of 90-98°C to carry out surface compound phosphating treatment for 15 minutes (the solution is no longer bubbling by visual inspection), and the coating thickness is 5-8 μm.

[0025] Formula of compound phosphating solution (both industrial grade chemical materials): 40-70g / l of Maziv salt, 4-7g / l of nickel nitrate, 40-70g / l of manganese nitrate, 2-5g / l of sodium fluoride.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com