High-strength and wear-resistant castable for middle back section of blast furnace water slag punching groove

A blast furnace water slag and castable technology, applied in the field of high-strength wear-resistant castables, can solve problems such as difficult decomposition, and achieve the effects of low cost, cost reduction and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

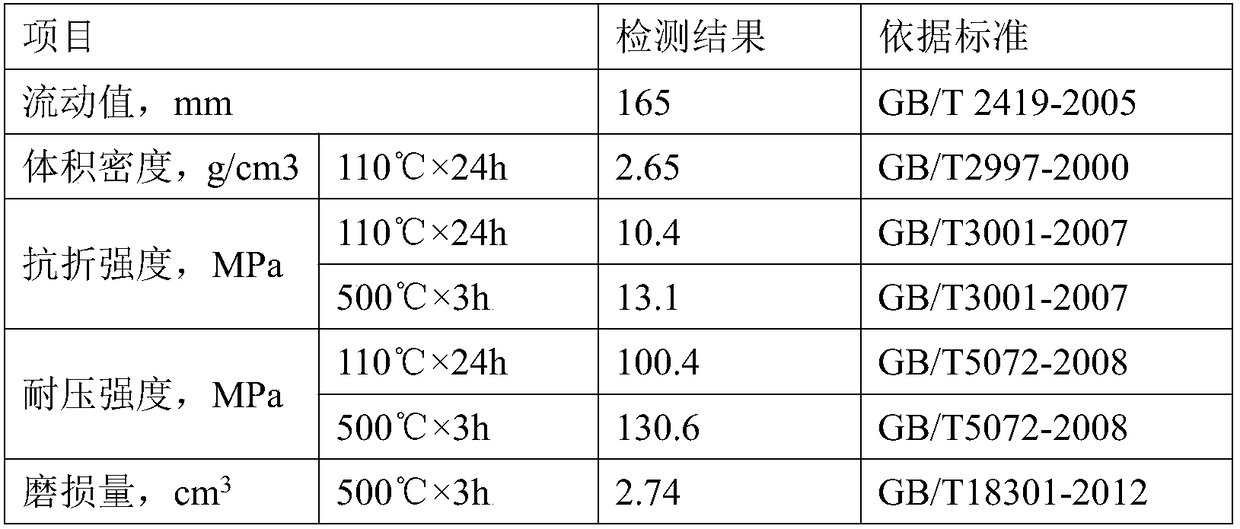

Embodiment 1

[0026] A high-strength wear-resistant castable used in the middle and back sections of the blast furnace slag punching tank, which is composed of main raw material components and external components; the main raw materials and their mass percentages are: waste ceramic aggregate 45%, brown corundum 25%, Silicon carbide fine powder 4.5%, calcium aluminate cement 16%, chromium trioxide fine powder 2%, heat-resistant steel fiber 3%, silicon dioxide fine powder 4%. The mass percentages of the added components and the total mass of the above-mentioned main raw materials are: 0.1% of organic explosion-proof fiber, 0.5% of boron carbide, 0.2% of water reducer (polycarboxylate water reducer FS65 added 0.05%, sodium hexametaphosphate Addition 0.15%), retarder 0.03% (citric acid addition 0, oxalic acid addition 0.03%).

[0027] Then add 5.5wt% water of the above mixture, stir evenly, vibrate and shape, and finally maintain at room temperature for 12-48 hours to release the mold.

[0028...

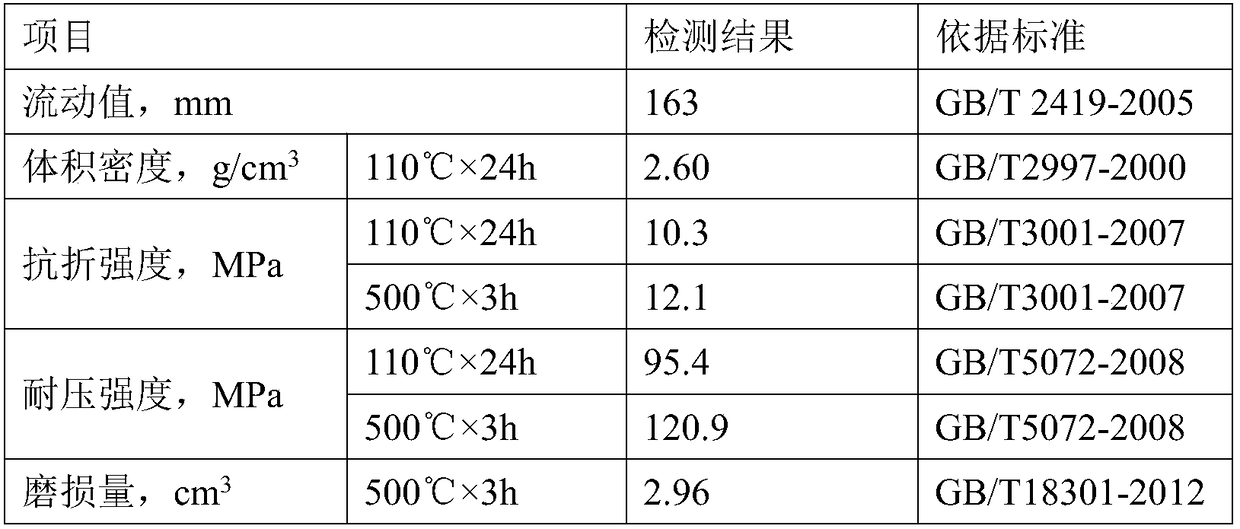

Embodiment 2

[0035] A high-strength wear-resistant castable used in the middle and back sections of blast furnace slag punching tanks, which is composed of main raw material components and external components; the main raw materials and their mass percentages are: waste ceramic aggregate 55%, brown corundum 13%, Silicon carbide fine powder 2%, calcium aluminate cement 20%, chromium trioxide fine powder 1.5%, heat-resistant steel fiber 2%, silicon dioxide fine powder 5%. The mass percentages of the added components and the total mass of the above-mentioned main raw materials are: 0.08% of organic explosion-proof fiber, 1.5% of boron carbide, 0.2% of water reducer (polycarboxylate water reducer FS65 added 0.1%, sodium hexametaphosphate Addition amount 0.1%), retarder 0.06% (citric acid addition amount 0.05%, oxalic acid addition amount 0.01%).

[0036] Then add 6.5wt% water of the above mixture, stir evenly, vibrate and form, and finally maintain at room temperature for 12-48 hours to demoul...

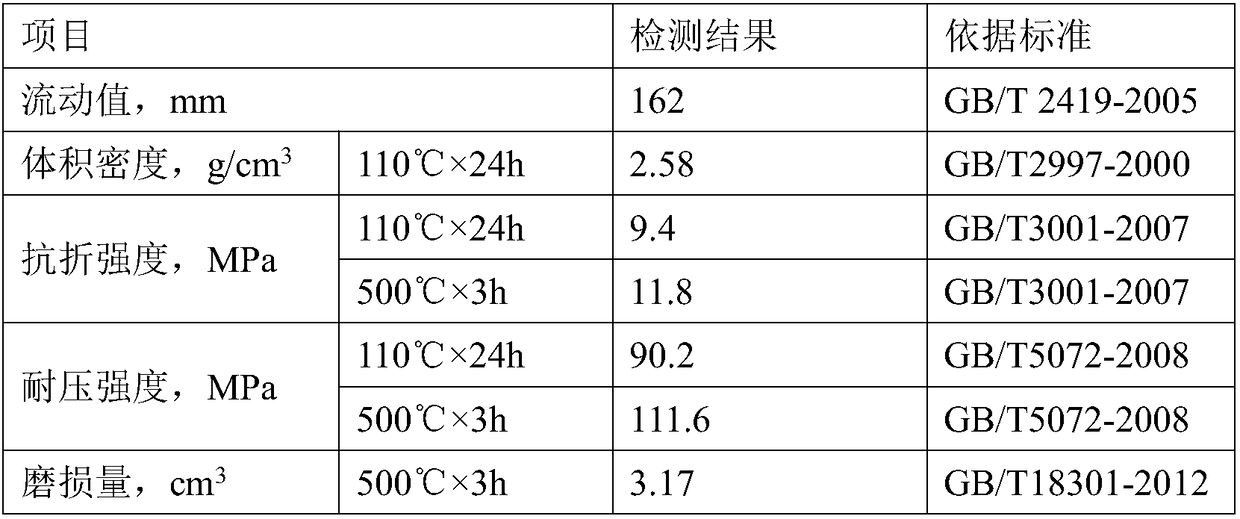

Embodiment 3

[0044]A high-strength wear-resistant castable for the middle and rear sections of the blast furnace slag punching tank, which is composed of main raw material components and external components; the main raw materials and their mass percentages are: waste ceramic aggregate 65%, brown corundum 3%, Silicon carbide fine powder 5%, calcium aluminate cement 18%, chromium trioxide fine powder 1%, heat-resistant steel fiber 1%, silicon dioxide fine powder 6%. The mass percentages of the added components and the total mass of the above-mentioned main raw materials are: 0.05% of organic explosion-proof fiber, 1% of boron carbide, 0.15% of water reducer (polycarboxylate water reducer FS65 added 0.15%, sodium hexametaphosphate Addition 0), retarder 0.04% (citric acid addition 0.04%, oxalic acid addition 0).

[0045] Then add 7.5wt% water of the above mixture, stir evenly, vibrate and shape, and finally maintain at room temperature for 12-48 hours to demould.

[0046] Al in used waste ce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com