Method for generating A2B2O7 type thermal barrier coating material by laser-induced high-temperature solid-phase reaction

An A2B2O7, high-temperature solid-phase reaction technology, applied in heating inorganic powder coating and other directions, can solve the problems of high raw material requirements, high equipment energy consumption requirements, low safety performance, etc., to avoid high reaction temperature and high raw material requirements. , to avoid the effect of high equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

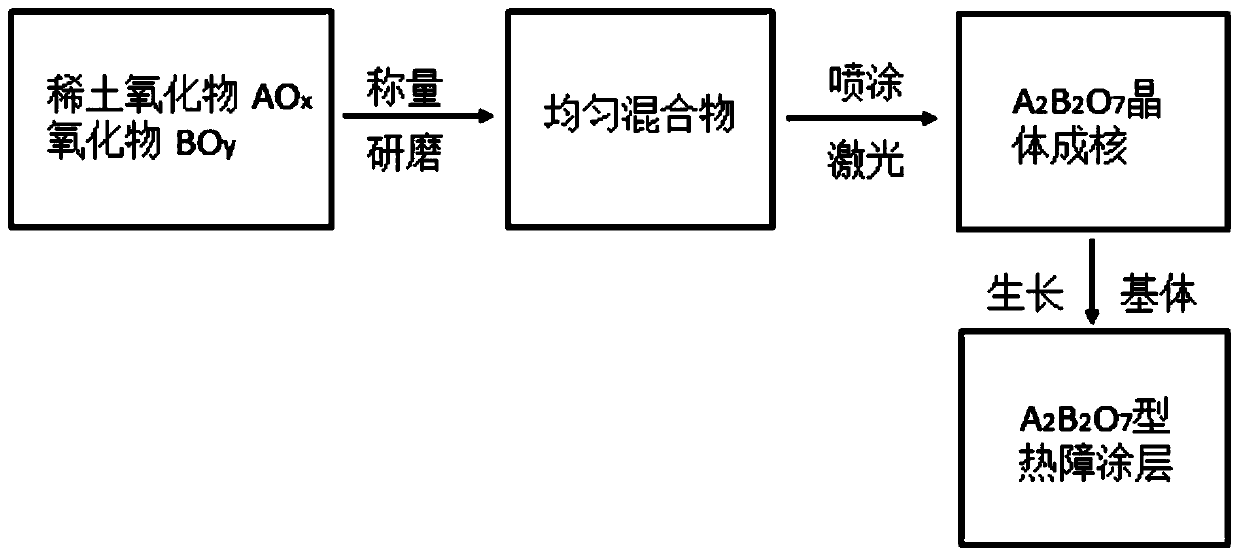

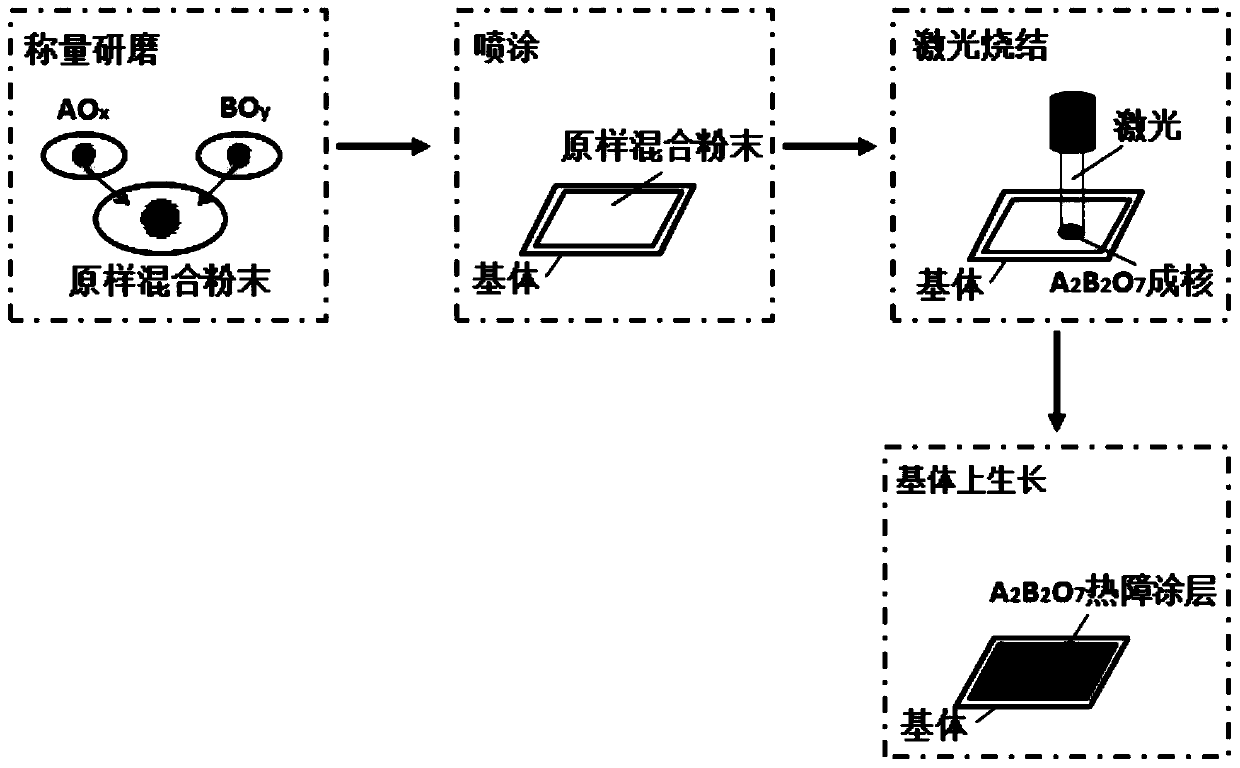

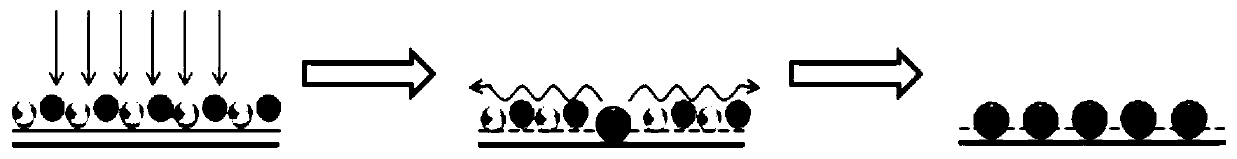

[0040] Such as Figure 1-3 As shown, a laser-induced high-temperature solid-state reaction to generate Yb 2 Zr 2 o 7 A method for a type thermal barrier coating material, comprising the steps of:

[0041] (1), get the Yb that purity is 99.9% 2 o 3 and ZrO with a purity of 99.9% 2 , whose molar ratio Yb 2 o 3 : ZrO 2 1:2, ball milled for 2 hours under the condition of ball-to-material ratio of 5:1 and rotating speed of 300r / s to obtain mixed powder;

[0042] (II), the mixed powder of step (I) is evenly distributed on the surface of the substrate, the substrate is a copper metal plate, the mixed powder is evenly distributed, the surface is smooth, and the thickness of the mixed powder is 0.5mm;

[0043] (III), irradiating the laser light on the surface of the substrate in step (II), under the action of continuous laser light with a wavelength of 980nm, the optical power density of the control laser light is 500W / cm 2 , the duration of the laser action is 5s, and the hi...

Embodiment 2

[0045] Such as Figure 1-3 As shown, a laser-induced high-temperature solid-state reaction to generate Yb 2 Zr 2 o 7 -Y 2 Zr 2 o 7A method for a type composite thermal barrier coating material, comprising the steps of:

[0046] (1), get the Yb that purity is 99.9% 2 o 3 , Y with a purity of 99.9% 2 o 3 and ZrO with a purity of 99.9% 2 , whose molar ratio Yb 2 o 3 : Y 2 o 3 : ZrO 2 0.5:0.5:2, ball milling for 2 hours at a ball-to-material ratio of 5:1 and a rotational speed of 300r / s to obtain a mixed powder;

[0047] (II), the mixed powder of step (I) is evenly distributed on the surface of the substrate, the substrate is a copper metal plate, the mixed powder is evenly distributed, the surface is smooth, and the thickness of the mixed powder is 0.5mm;

[0048] (III), irradiating the laser light on the surface of the substrate in step (II), under the action of continuous laser light with a wavelength of 980nm, the optical power density of the control laser ligh...

Embodiment 3

[0050] Such as Figure 1-3 As shown, a laser-induced high-temperature solid-state reaction to generate Gd 2 Zr 2 o 7 A method for a type thermal barrier coating material, comprising the steps of:

[0051] (1), get the Gd that purity is 99.9% 2 o 3 and ZrO with a purity of 99.9% 2 , whose molar ratio Gd 2 o 3 : ZrO 2 1:2, ball milling for 2 hours at a ball-to-material ratio of 5:1 and a rotational speed of 300r / s to obtain a mixed powder;

[0052] (II), the mixed powder of step (I) is evenly distributed on the surface of the substrate, the substrate is a copper metal plate, the mixed powder is evenly distributed, the surface is smooth, and the thickness of the mixed powder is 0.5mm;

[0053] (III), laser irradiation on the surface of the substrate of step (II), under the action of continuous laser light with a wavelength of 980nm, the optical power density of the control laser is 400W / cm 2 , the laser scans the surface of the matrix in a "bow" shape at a scanning spee...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com