A kind of preparation method of perovskite type high emissivity spherical agglomerated powder

A high-emissivity, perovskite-type technology, applied in chemical instruments and methods, manganate/permanganate, cobalt compounds, etc., can solve the problem of irregular powder shape, limited application fields, uneven particle size, etc. problem, to achieve the effect of high sphericity, process safety, and uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

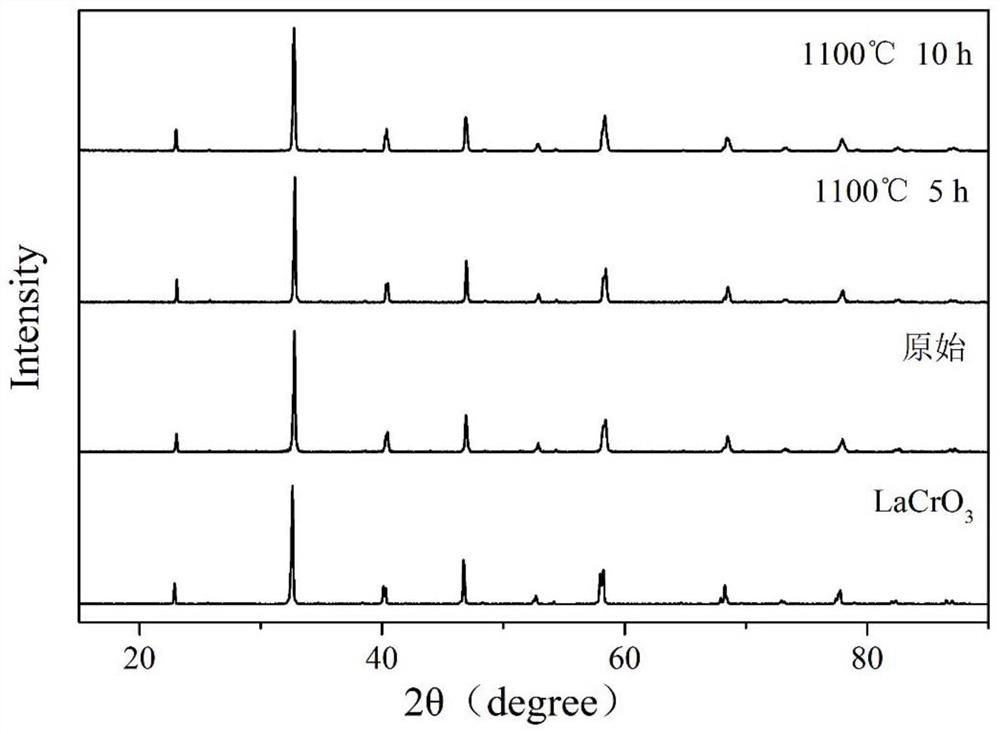

[0029] (1) Select analytically pure La 2 o 3 、Cr 2 o 3 and MnO 2 The powder is used as a raw material, and it is kept in an oven at 100°C for 18 hours to remove crystal water, and immediately after the powder is cooled, the LaCr 0.8 mn 0.2 o 3 Weigh the required raw materials; put the weighed raw materials into the ball mill tank, add absolute ethanol, select zirconia as the grinding balls, the diameters of the grinding balls are 10mm, 5mm, 2mm, and the mass ratio is 2: 2:1, the mass ratio of balls to materials is 4:1, ball milled in a planetary ball mill at a speed of 300r / min for 5h, and the obtained slurry is subjected to rotary steaming, the rotating speed of which is 30r / min, the temperature of the water bath is 70°C, and then put Dry in an oven at 80°C for 12 hours to remove residual absolute ethanol to obtain a powder.

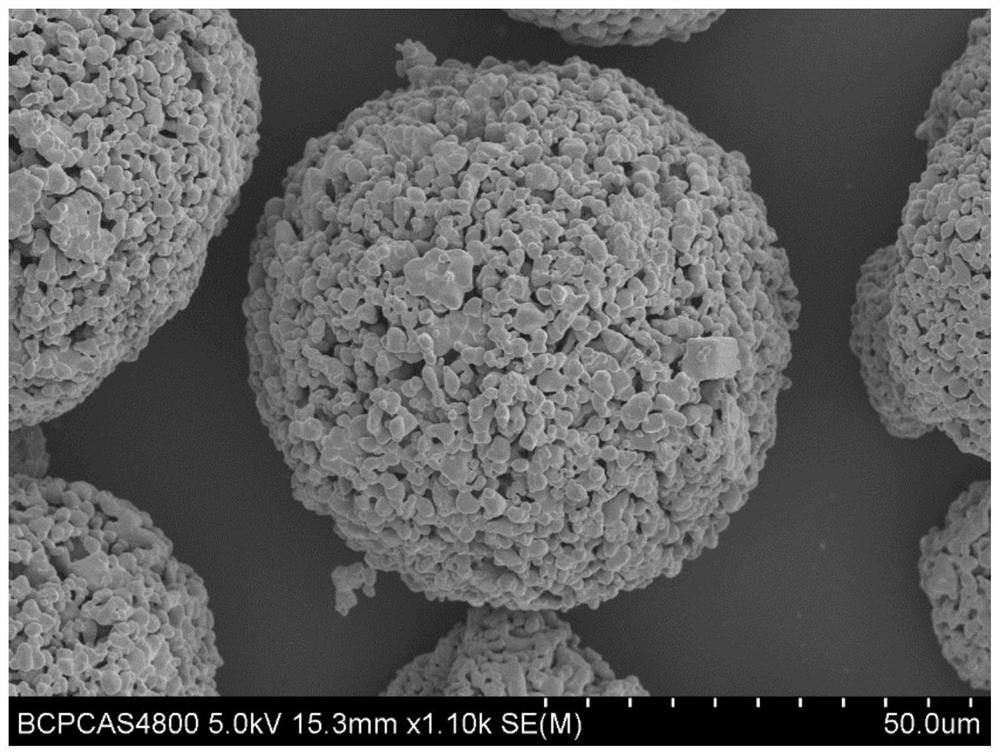

[0030] (2) the powder obtained in step (1) and deionized water, and the binding agent PVA are put into a ball mill jar, and the total mass of th...

Embodiment 2

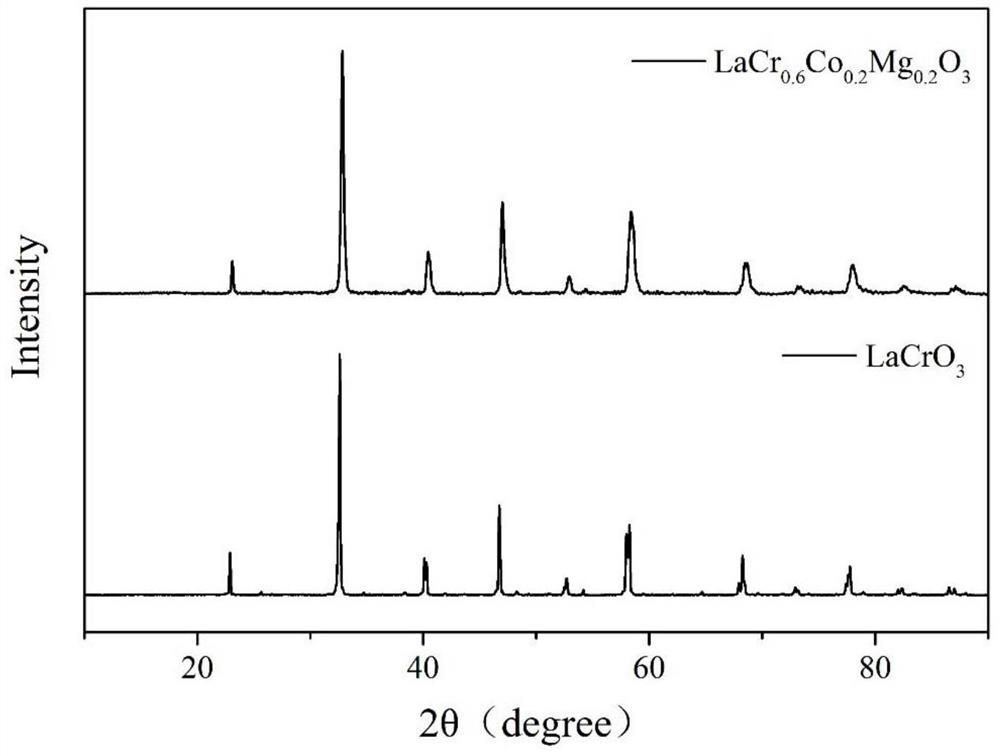

[0048] (1) Select analytically pure La 2 o 3 、Cr 2 o 3 , MgO and Co 2 o 3 The powder is used as a raw material, and it is kept in an oven at 150°C for 12 hours to remove crystal water, and immediately after the powder is cooled according to LaCr 0.6 co 0.2 Mg 0.2 o 3 The proportioning ratio weighs the required raw materials; puts the weighed raw materials into the ball mill tank, adds absolute ethanol, selects zirconia as the grinding balls, the diameters of the grinding balls are 10mm, 5mm, 2mm, and the mass ratio is 2: 2:1, the mass ratio of ball to material is 4:1, ball milled in a planetary ball mill at a speed of 500r / min for 3h, and the obtained slurry was subjected to rotary steaming, the rotating speed of which was 60r / min, the temperature of the water bath was 80°C, and then put Dry in an oven at 120°C for 6 hours to remove residual absolute ethanol to obtain a powder.

[0049] (2) the powder obtained in step (1) and deionized water, and the binding agent PVA...

Embodiment 3

[0062] (1) Select analytically pure La 2 o 3 、Cr 2 o 3 and Co 2 o 3 The powder is used as a raw material, and it is kept in an oven at 120°C for 12 hours to remove crystal water, and immediately after the powder is cooled, according to LaCr 0.7 co 0.3 o 3 The proportioning ratio weighs the required raw materials; puts the weighed raw materials into the ball mill tank, adds absolute ethanol, selects zirconia as the grinding balls, the diameters of the grinding balls are 10mm, 5mm, 2mm, and the mass ratio is 2: 2:1, the mass ratio of the ball to the material is 4:1, ball milled in a planetary ball mill at a speed of 500r / min for 3h, and the obtained slurry was subjected to rotary steaming at a speed of 45r / min, the temperature of the water bath was 70°C, and then put Dry in an oven at 120°C for 6 hours to remove residual absolute ethanol to obtain a powder.

[0063] (2) the powder obtained in step (1) and deionized water, and the binding agent PVA are put into a ball mil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

| fluidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com