Boron nitride-boron carbide-graphite composite heating element used for high temperature electric heating

A boron carbide and boron nitride technology, which is applied in the field of boron nitride (BN)-boron carbide (B4C)-graphite composite heating element, can solve the problem that the surface coating requirements of the ultra-high temperature heating element and the thermal expansion coefficient of the surface coating cannot be satisfied. Non-uniformity, unstable heating element resistivity, etc., to achieve good chemical stability, ensure electrical conductivity, and good high-temperature chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

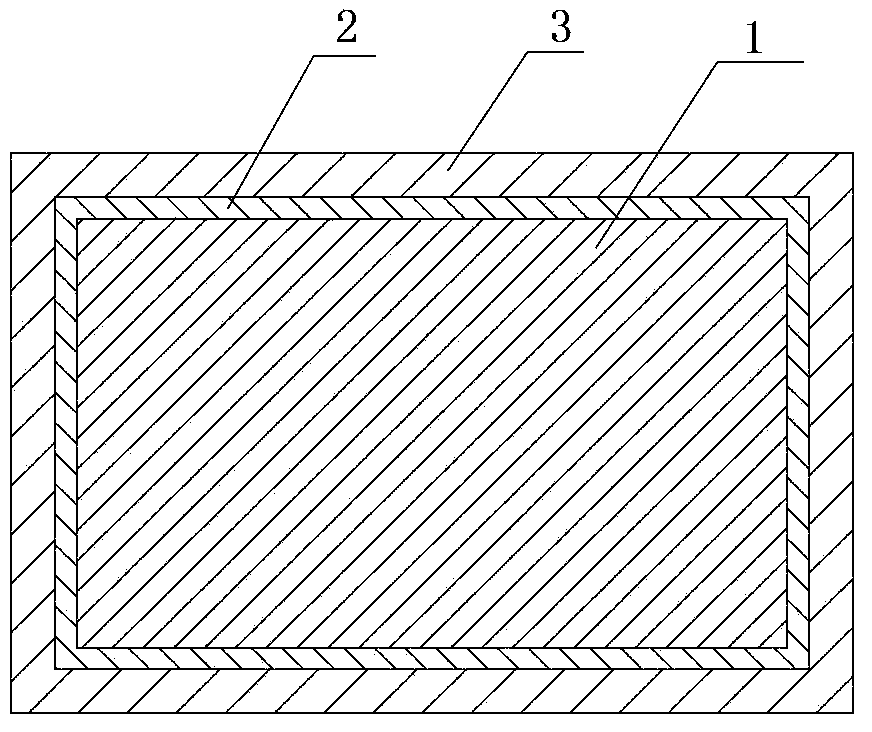

[0030] A graphite block with a size of 100mm×20mm×10mm at the hot end is prepared, and its surface is polished. The polished graphite was placed in a high-temperature vacuum furnace, heated to 2200° C., kept at a temperature of 60 hours, and subjected to high-temperature pretreatment to obtain graphite matrix 1 .

[0031] Place the graphite substrate after high temperature pretreatment in a high temperature atmosphere reaction furnace, and put C 3 h 6 Gas and BCl 3 The gas is mixed at a molar ratio of 1:12 and then passed into the high-temperature reaction furnace, and the gas flow rate is controlled at 1L / min. The temperature of the chemical vapor deposition is controlled at 2200° C., and the deposition time is 20 hours. After a chemical vapor phase reaction, a layer of boron carbide (B) with a thickness of 0.5 mm is formed on the surface of the graphite heating element. 4 C) Middle layer 2.

[0032] will be deposited with boron carbide (B 4 C) The graphite matrix of th...

Embodiment 2

[0036] A graphite block with a hot end size of 30mm×10mm×4mm was prepared, and its surface was polished. The polished graphite was placed in a high-temperature vacuum furnace, heated to 2300° C., kept for 100 hours, and subjected to high-temperature pretreatment to obtain graphite matrix 1 .

[0037] Place the graphite substrate after high temperature pretreatment in a high temperature atmosphere reaction furnace, and put C 3 h 6 Gas and BCl 3 The gas is mixed at a molar ratio of 1:10 and then passed into the high-temperature reaction furnace, and the gas flow rate is controlled at 5L / min. The temperature of the chemical vapor deposition is controlled at 2300° C., and the deposition time is 5 hours. After a chemical vapor phase reaction, a layer of boron carbide (B) with a thickness of 0.3 mm is formed on the surface of the graphite heating element. 4 C) Middle layer 2.

[0038] will be deposited with boron carbide (B 4 C) The graphite matrix of the middle layer is place...

Embodiment 3

[0042] A graphite block with a hot end size of 50mm×5mm×5mm was prepared, and its surface was polished. The polished graphite was placed in a high-temperature vacuum furnace, heated to 2000° C., kept for 80 hours, and subjected to high-temperature pretreatment to obtain graphite matrix 1 .

[0043] Place the graphite substrate after high temperature pretreatment in a high temperature atmosphere reaction furnace, and put C 3 h 6 Gas and BCl 3 The gas is mixed at a molar ratio of 1:15 and then passed into the high-temperature reaction furnace, and the gas flow rate is controlled at 8L / min. The temperature of the chemical vapor deposition is controlled at 2200° C., and the deposition time is 5 hours. After a chemical vapor phase reaction, a layer of boron carbide (B) with a thickness of 0.4 mm is formed on the surface of the graphite heating element. 4 C) Middle layer 2.

[0044] will be deposited with boron carbide (B 4 C) The graphite matrix of the middle layer is placed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com